2025 Top 5 Circuit Board Assembly Trends You Can't Afford to Miss

As we look towards 2025, the landscape of circuit board assembly is poised for remarkable evolution, driven by technological advancements and growing industry demands. According to a recent market report by Market Research Future, the global circuit board assembly market is expected to reach approximately $80 billion by 2025, highlighting an annual growth rate of 4.5%. This growth underscores the critical importance of staying ahead of emerging trends in the sector.

Industry expert Dr. Lisa Chen, a leading voice in electronic manufacturing and circuit technologies, emphasizes the urgency of adaptation in this rapidly changing environment. She states, “The future of circuit board assembly will be shaped by innovative materials, automation, and sustainability practices that not only enhance production efficiency but also align with environmental standards.” As businesses strategize for the future, understanding these trends will be vital for maintaining competitive advantage and meeting evolving customer expectations.

In light of these insights, it is imperative to explore the top five circuit board assembly trends that industry stakeholders cannot afford to overlook. By doing so, manufacturers can harness new opportunities, optimize their processes, and ensure they are well-positioned to thrive in the foreseeable future.

Emergence of AI in Circuit Board Design and Production Efficiency

The emergence of artificial intelligence (AI) is set to revolutionize the circuit board design and production process, presenting opportunities for both innovation and efficiency. AI technologies are increasingly being integrated into design software, enabling engineers to automate repetitive tasks and optimize layout decisions. This advanced capability allows for more complex designs to be developed in a fraction of the time traditionally required, minimizing human error and enhancing overall product quality.

In the production phase, AI-driven systems are streamlining manufacturing processes by utilizing predictive analytics to anticipate equipment failures and optimize maintenance schedules. This predictive capability ensures minimal downtime and maximizes throughput, leading to a significant reduction in production costs. Furthermore, AI can analyze historical data to refine quality control measures, ensuring that each circuit board meets stringent industry standards. As companies embrace these AI advancements, they are poised to significantly improve production efficiency while pushing the boundaries of circuit board technology.

2025 Top 5 Circuit Board Assembly Trends

Sustainability Practices Transforming Circuit Board Materials and Manufacturing

Sustainability practices are poised to revolutionize the landscape of circuit board materials and manufacturing by 2025. As environmental concerns escalate, companies are increasingly prioritizing eco-friendly materials, such as biodegradable substrates and recycled components. The shift towards these sustainable materials not only helps reduce waste but also aligns with global initiatives aimed at minimizing environmental impact. By adopting greener alternatives, manufacturers can improve their brand image while appealing to eco-conscious consumers.

In addition to sustainable materials, innovative manufacturing processes are emerging that emphasize energy efficiency and waste reduction. Techniques like additive manufacturing and advanced chemical methodologies are now being employed to streamline production and reduce carbon footprints. These practices not only enhance the overall sustainability of circuit board assembly but also improve efficiency and reduce costs in the long run. As the industry embraces these trends, it sets a new standard for responsible production, ultimately contributing to a healthier planet.

2025 Top 5 Circuit Board Assembly Trends You Can't Afford to Miss

| Trend | Description | Impact on Sustainability | Future Outlook |

|---|---|---|---|

| Eco-friendly Materials | Use of biodegradable and recyclable materials in circuit board manufacturing. | Reduces plastic waste and increases product lifecycle. | Expected to be mainstream by 2025. |

| Energy-efficient Manufacturing | Implementing processes that reduce energy consumption during production. | Significantly lowers carbon footprint. | Increased adoption of renewable energy sources in factories. |

| Waste Reduction Practices | Strategies to minimize waste during production and assembly. | Enhances resource efficiency and reduces disposal costs. | Projected to improve by 30% by 2025. |

| Life Cycle Assessment | Analyzing the environmental impact of a product from creation to disposal. | Provides insights for sustainable product development. | Becoming a standard practice in the industry. |

| Circular Economy Initiatives | Emphasizing reuse and recycling in circuit board life cycles. | Helps close the loop on electronic waste. | Expected growth in circular economy models by 2025. |

Rise of Automation and Robotics in Assembly Processes

The rise of automation and robotics within the assembly processes is set to reshape the landscape of the global electronics manufacturing services market. By 2032, the market is projected to expand significantly, from an estimated $648.1 billion in 2025 to approximately $1,033.17 billion, marking a robust compound annual growth rate (CAGR) of 6.9%. This growth is propelled by advancements in robotic motor technology, which is also expected to grow at a CAGR of 3.8%, reaching a value of around $18.92 billion by 2032.

As developed nations increasingly adopt "lighthouse factories", the integration of digital technologies and the Industrial Internet of Things (IIoT) is driving automation upgrades. These factories emphasize artificial intelligence and are fundamentally changing manufacturing practices. For example, initiatives in construction automation—such as partnerships focused on utilizing robotics to expedite and reduce construction costs—illustrate the broader trend of employing automation to enhance efficiency. Statistics indicate that 81% of construction firms plan to incorporate robots over the next decade, primarily to address labor shortages while improving safety and environmental considerations.

Increasing Role of IoT in Smart Circuit Board Applications

The increasing role of the Internet of Things (IoT) is revolutionizing smart circuit board applications, making them more connected, intelligent, and efficient. As devices become more integrated into our daily lives, circuit boards must evolve to meet the demands of this interconnected landscape. IoT-enabled circuit boards are not just about basic connectivity; they are designed to facilitate real-time data exchange and perform complex computations at the edge, thereby enhancing functionality and performance.

Moreover, the incorporation of advanced sensors and communication technologies into circuit boards allows for unprecedented levels of automation and control. For instance, in sectors like healthcare, smart circuit boards can monitor patient vitals and communicate updates seamlessly to medical professionals through IoT networks. This seamless integration of IoT transforms traditional circuit board applications into robust, smart systems capable of adaptive responses and predictive maintenance, which are essential for modern industries seeking to leverage data-driven decisions for operational efficiency. As these trends continue to develop, businesses must prioritize adopting smart circuit board solutions to remain competitive in the evolving market.

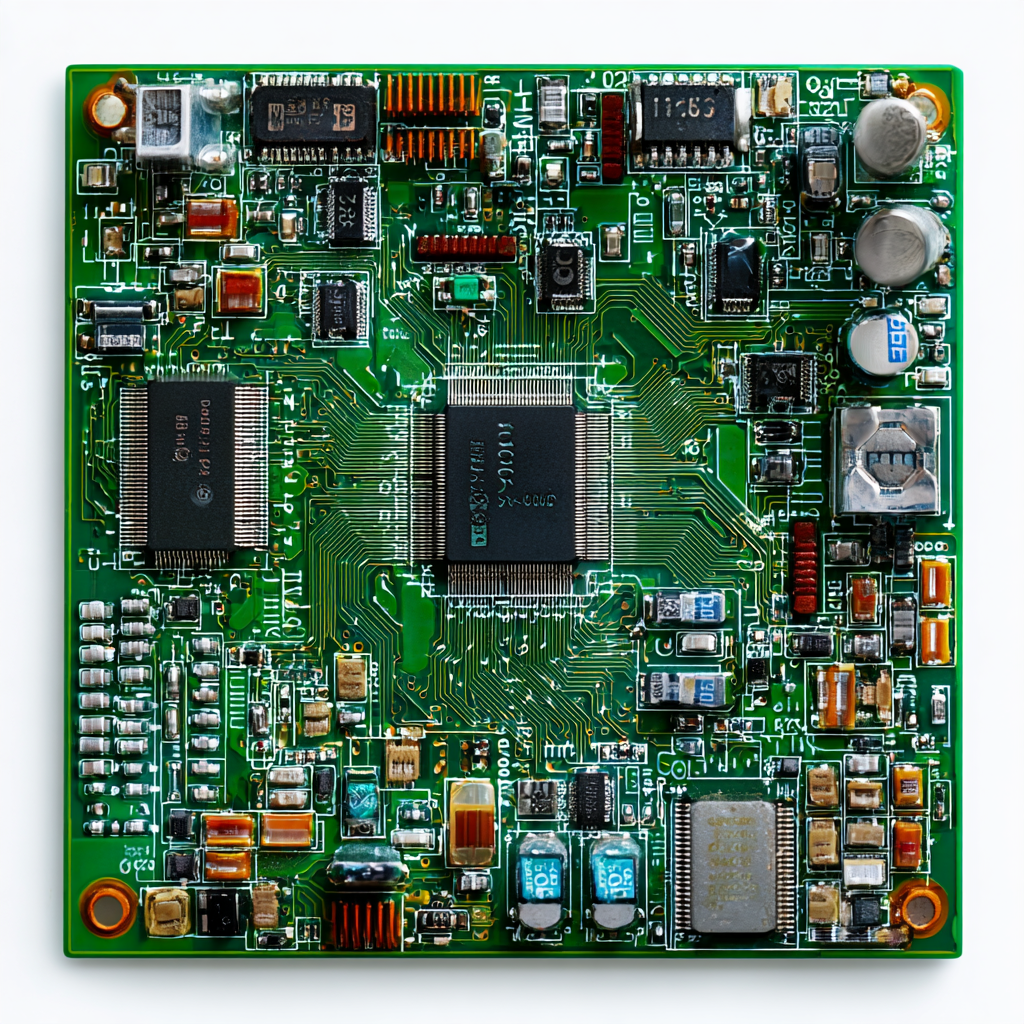

Advancements in PCB Testing Technologies for Quality Assurance

Advancements in PCB testing technologies have become crucial for ensuring quality assurance in circuit board assembly as we approach 2025. The rise of automated testing processes has significantly enhanced the accuracy and efficiency of PCB inspections.

Automated Optical Inspection (AOI) systems, for instance, can quickly identify defects in both surface-mount and through-hole components, reducing human error and streamlining production times.

Automated Optical Inspection (AOI) systems, for instance, can quickly identify defects in both surface-mount and through-hole components, reducing human error and streamlining production times.

Tips: Embrace the integration of AI in testing procedures. AI-driven software can analyze test data more precisely, predicting potential failures before they occur. Implementing machine learning algorithms can optimize inspection processes, allowing for real-time adjustments based on previous performance metrics.

Additionally, the utilization of innovative testing methods such as thermal imaging and X-ray inspection has gained traction. These technologies can uncover hidden issues within multilayer boards that traditional methods may miss. As manufacturers increasingly rely on these advanced techniques, the overall reliability of circuit boards is set to improve, ultimately leading to higher customer satisfaction and lower return rates.

Tips: Regularly train your quality assurance team on the latest testing technologies. Keeping your staff updated on emerging tools can maximize the effectiveness of your quality control processes, ensuring that your products consistently meet industry standards.

Related Posts

-

Exploring Innovative Alternatives in PCB Electronics for Modern Applications

-

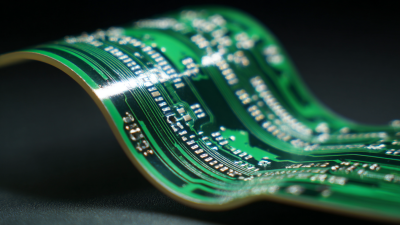

Innovative Applications of Flexible PCB Boards in Modern Electronics

-

Unlocking Success: The Advantages of Advanced PCB Fabrication Techniques for Global Buyers

-

How to Design and Manufacture a High-Quality Printed Circuit Board from Scratch

-

Addressing Common Challenges in Sourcing the Best PCB Circuits for Global Buyers

-

Digital Insights and Tips for Optimizing Your Flexible Printed Circuit Design Process