2025 Top PCB Printing Trends: What You Need to Know for Success

As we approach 2025, the landscape of PCB printing is rapidly evolving, driven by technological advancements and increasing demands for more efficient manufacturing processes. Understanding the latest trends in PCB printing is essential for businesses seeking to maintain a competitive edge in the electronics industry. This comprehensive overview highlights the critical developments and innovations that are shaping the future of PCB printing, ensuring that companies are well-prepared to adapt and thrive in a changing marketplace.

The trends we will explore encompass a variety of factors including advancements in printing technology, evolving materials, and shifts in consumer demands. Emphasizing the importance of sustainability and automation, these developments not only enhance the quality and reliability of printed circuit boards but also streamline production processes, reduce waste, and lower costs. Staying informed about these key trends will empower businesses to make strategic decisions, thus ensuring their success in the dynamic realm of PCB printing.

Emerging Technologies Driving PCB Printing Advancements in 2025

As we approach 2025, the realm of PCB printing is witnessing significant advancements driven by emerging technologies. Innovations such as 3D printing, advanced materials, and automation are reshaping how PCBs are designed and manufactured. These technologies not only enhance the efficiency of production processes but also enable manufacturers to deliver highly customized and intricate designs that meet the ever-evolving demands of the electronics industry.

Tips: Stay updated with industry trends by subscribing to relevant journals and attending conferences. Networking with professionals can provide insights into new technologies that can be incorporated into your workflow.

Moreover, the rise of IoT and smart devices has created a growing need for flexible and high-density PCBs. The adoption of smart manufacturing techniques is crucial in addressing these needs, making it essential for companies to invest in data analytics and machine learning. Leveraging these technologies will facilitate predictive maintenance and optimize production schedules, ultimately leading to cost reductions and improved product quality.

Tips: Implementing collaborative tools can enhance communication among teams, ensuring that everyone is informed about the latest technology integrations and project updates.

2025 Top PCB Printing Trends: What You Need to Know for Success

| Trend | Description | Impact | Technologies Involved | Potential Market Growth (%) |

|---|---|---|---|---|

| Automated PCB Design | Increase in automation tools for PCB design processes. | Improves efficiency and reduces time to market. | AI, Machine Learning | 15% |

| Flexible and Printed Electronics | Growing trend in creating flexible circuits using printing technology. | Enables new applications in wearables and IoT devices. | Inkjet Printing, 3D Printing | 20% |

| 3D PCB Printing | Advances in 3D printing technology for faster prototyping. | Reduces prototyping costs and speeds up design iterations. | Additive Manufacturing | 25% |

| Sustainable Materials | Shift towards using eco-friendly materials in PCB production. | Addresses environmental concerns and regulations. | Biodegradable Substrates | 10% |

| High-Frequency PCBs | Increased demand for high-frequency applications, such as 5G. | Enhanced performance in telecommunications and electronics. | Material Advancements, RF Technologies | 30% |

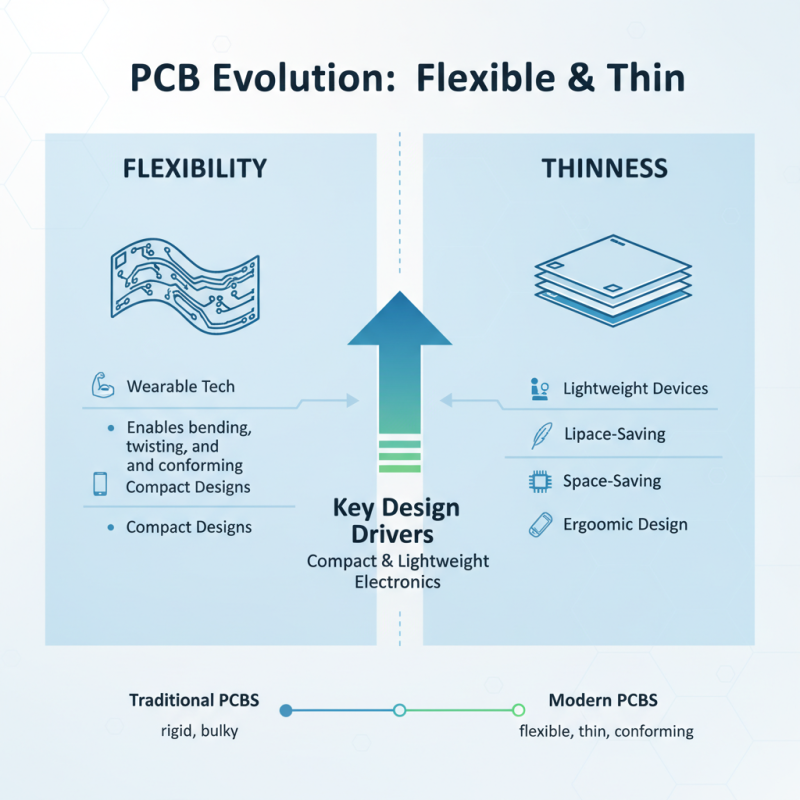

The Impact of Flexibility and Thinness on PCB Design Trends

The evolution of printed circuit boards (PCBs) is significantly influenced by the trends of flexibility and thinness, which have become essential design elements in various applications. Flexibility in PCB design addresses the growing demand for compact and lightweight electronic devices. Engineers are increasingly adopting flexible materials that allow PCBs to bend, twist, and conform to the contours of other components or packaging. This capability not only enhances the ergonomic design of products but also enables innovative applications in areas such as wearable technology and automotive interfaces, where space and weight are critical considerations.

Moreover, the trend toward thinner PCBs complements the push for more efficient designs. As consumer electronics continue to shrink in size, the thickness of PCBs is also reducing, leading to more streamlined devices. This shift to ultra-thin designs presents challenges, particularly in maintaining durability and electrical performance. Manufacturers continue to explore advanced materials and fabrication techniques that cater to these needs. The focus on thinness further promotes miniaturization, allowing for intricate designs packed with features, thereby enhancing overall functionality while meeting consumer expectations for sleek, modern aesthetics. As these trends unfold, they represent an exciting frontier in PCB design, pushing the boundaries of innovation and usability across various industries.

Sustainability Practices Reshaping the PCB Printing Industry

The PCB printing industry is undergoing a significant transformation driven by sustainability practices. As environmental concerns grow, companies are increasingly adopting eco-friendly materials and processes. This shift not only addresses regulatory demands but also meets the expectations of consumers who prioritize sustainable practices. From utilizing biodegradable substrates to implementing energy-efficient manufacturing techniques, the industry is working towards reducing its ecological footprint while maintaining high-quality standards.

Moreover, the integration of circular economy principles is becoming pivotal in PCB printing. Manufacturers are exploring ways to recycle and repurpose materials, thereby minimizing waste and maximizing resource efficiency. Innovations such as closed-loop systems, which ensure that production waste is reintegrated into the manufacturing process, are gaining traction. This approach not only enhances sustainability but can also lead to cost savings, making it an attractive option for businesses aiming to remain competitive in the market. As the industry moves forward, these practices will likely become essential components of successful PCB printing strategies.

Market Growth Projections for PCB Printing: A 2025 Outlook

The PCB printing market is expected to experience significant growth by 2025, driven by the increasing demand for advanced electronic devices and the rise of smart technologies. As industries such as automotive, telecommunications, and consumer electronics embrace miniaturization and connectivity, PCB printing processes will need to adapt to accommodate more complex designs and higher quality standards. Analysts project a considerable market expansion, with innovations in materials and techniques enhancing production efficiency and product performance.

Tips for Success in PCB Printing by 2025:

- Embrace Automation: Integrating automated processes can reduce human error and increase production speed. Companies should invest in smart manufacturing technologies that allow for real-time monitoring and adjustments.

- Focus on Sustainability: As environmental concerns continue to rise, adopting eco-friendly materials and practices will not only meet regulatory requirements but also appeal to environmentally conscious consumers. Consider implementing recycling practices for waste materials generated during the PCB manufacturing process.

Staying ahead in PCB printing requires a proactive approach to these trends. By aligning strategies with market projections and innovating around sustainability and automation, businesses can position themselves for success in the competitive landscape of 2025.

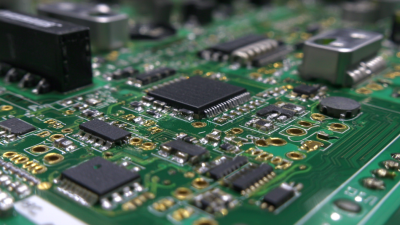

Innovative Materials Transforming PCB Printing Techniques in 2025

The landscape of PCB printing is rapidly evolving, with innovative materials leading the way toward more efficient and versatile manufacturing techniques in 2025. A recent industry report indicates that the global market for advanced PCB materials is projected to reach $20 billion by 2025, driven by the growing demand for high-performance electronics and miniaturization. These materials enhance thermal conductivity, reduce weight, and improve overall reliability, which is crucial for modern applications in sectors like telecommunications, automotive, and consumer electronics.

One of the most notable trends is the increasing use of additive manufacturing techniques, such as 3D printing. This method allows for greater design flexibility and reduced waste, which not only streamlines production but also supports sustainability initiatives. Furthermore, the integration of flexible and printed electronics is expanding the horizons of PCB applications. According to recent studies, the market for flexible PCBs is expected to grow at a CAGR of 10.1% through 2025, underscoring the necessity for manufacturers to adapt to these emerging technologies.

Tip: Consider investing in research and development to explore new materials that can enhance your PCB products. Collaborating with suppliers who specialize in innovative materials can provide a competitive edge in the ever-evolving landscape. Additionally, staying updated on industry trends and best practices will be crucial for keeping pace with advancements in PCB printing technologies.

2025 Top PCB Printing Trends: What You Need to Know for Success

This chart illustrates the projected growth of various innovative materials used in PCB printing techniques by 2025. The data outlines the increasing adoption rates of advanced materials like flexible substrates, high-frequency laminates, and eco-friendly inks.

Related Posts

-

Revolutionizing PCB Printing: Insights from the 138th China Import and Export Fair 2025

-

Unlocking Success: The Advantages of Advanced PCB Fabrication Techniques for Global Buyers

-

Unveiling PCB and Assembly Innovations at the 138th China Import and Export Fair 2025

-

Innovative Uses in Aerospace and Challenges in Best Circuit Board Fabrication

-

Leading the Way: Unmatched Export Strength of China’s Top PCB Circuit Boards

-

Innovative Circuit Board Assembly Techniques Shaping the Future of Electronics