Understanding the Benefits and Applications of Flexible PCB Boards in Modern Electronics

In today's fast-paced technological landscape, the demand for compact, lightweight, and efficient electronic components has led to remarkable innovations in circuit design. Among these advancements, the flexible PCB board stands out as a pivotal solution that addresses the need for versatility and adaptability in modern electronics. Unlike traditional rigid circuit boards, flexible PCBs can be bent, twisted, and shaped to fit into diverse applications, making them ideal for a range of devices from smartphones to medical equipment. Their unique properties not only facilitate space-saving designs but also enhance durability and performance in environments where conventional boards may fail. As industries continue to explore novel ways to integrate technology into everyday objects, understanding the benefits and applications of flexible PCB boards will be crucial for engineers and designers aiming to push the boundaries of electronic functionality and design.

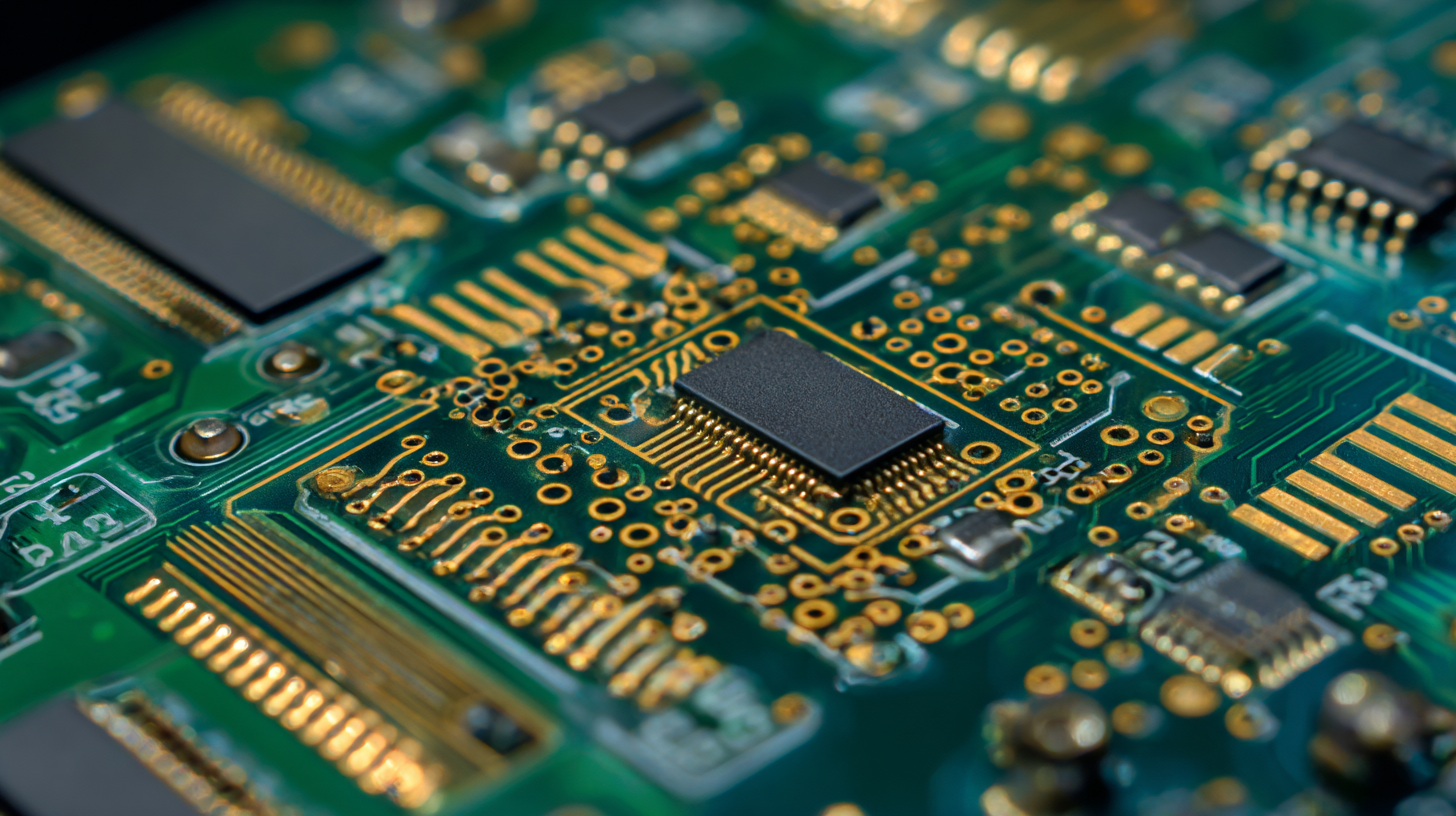

Benefits of Flexible PCB Boards in High-Density Interconnect Applications

Flexible PCB (Printed Circuit Board) boards have become integral to high-density interconnect (HDI) applications due to their unique advantages in modern electronics. One of the primary benefits of flexible PCBs is their ability to conform to complex shapes and designs, which allows for efficient use of space and weight reduction. This characteristic is essential in HDI applications where maximizing real estate on a circuit board is crucial. By facilitating tightly packed components and connections, flexible PCBs enable more intricate designs and higher performance.

Moreover, flexible PCBs offer enhanced durability and reliability in challenging environments. Their ability to bend and flex without damaging the circuit makes them ideal for devices that experience regular movement or vibration. In HDI applications, these properties ensure that the intricate interconnections remain intact, reducing the likelihood of failure and minimizing maintenance costs over the product's lifecycle. Overall, the integration of flexible PCBs into high-density interconnect designs not only supports more advanced technology but also provides a robust solution that meets the demands of modern electronic devices.

Key Applications of Flexible PCBs in Consumer Electronics and Wearable Devices

Flexible PCB (Printed Circuit Board) technology plays a crucial role in the advancement of consumer electronics and wearable devices. One of the primary applications of flexible PCBs is in smartphones, where their lightweight and compact nature allows for intricate designs that fit within slim profiles. These boards can easily conform to the curved surfaces and varying shapes of modern smartphones, enabling designers to create more innovative and aesthetically pleasing devices.

In addition to smartphones, flexible PCBs are fundamental in the rapidly expanding wearable technology market. Devices such as smartwatches, fitness trackers, and health monitors benefit from flexible PCBs due to their ability to withstand motion and bending. This adaptability not only enhances comfort for users but also enables the integration of various sensors and components in limited space. As wearable devices continue to gain popularity, the demand for flexible PCBs will further drive innovation in this area, leading to the development of even more sophisticated and functional electronic products.

Cost Efficiency: Analyzing the Economic Advantages of Flexible PCB Manufacturing

Flexible PCB (Printed Circuit Board) manufacturing is increasingly recognized for its cost efficiency and economic advantages in modern electronics. This is particularly relevant given the rising energy prices in the European Union, which have posed challenges to competitiveness within the industry. By utilizing flexible PCB technology, manufacturers can reduce material waste and minimize production costs. A report indicates that flexible PCBs can lead to a 30% reduction in manufacturing costs due to streamlined processes and less material usage.

Tips: Consider the environmental impact of your manufacturing choices. Flexible PCBs not only offer cost advantages but also support sustainability efforts in the electronics sector by reducing the carbon footprint associated with traditional rigid PCBs.

Moreover, as industries explore cost-effective solutions to navigate high energy prices, investing in flexible PCB technology can provide a significant competitive edge. With advancements in additive manufacturing, the potential for flexible PCBs to integrate seamlessly with renewable energy sources is becoming more pronounced, helping to further stabilize energy costs. Embracing flexibility in PCB design and production can enhance supply chain performance and improve product lifecycles, ultimately resulting in better economic outcomes in a rapidly evolving market.

Understanding the Benefits and Applications of Flexible PCB Boards in Modern Electronics - Cost Efficiency

| Dimension | Description | Economic Advantage |

|---|---|---|

| Material Cost | Flexible PCBs typically use less material compared to rigid boards, reducing expenses. | Lower initial material investments. |

| Production Yield | Higher yield rates due to fewer defects during manufacturing processes. | Reduced waste leads to cost savings. |

| Transportation Costs | Flexible boards are lighter and less bulky, which lowers shipping costs. | Decreased logistics expenses. |

| Assembly Efficiency | Easier integration in compact spaces, simplifying the assembly process. | Reduced labor costs during assembly. |

| Design Flexibility | Allows for innovative designs and configurations that rigid boards cannot provide. | Potential for higher market value due to unique product offerings. |

Impact of Flexible PCBs on Reducing Weight and Size in Modern Electronic Designs

Flexible PCBs (Printed Circuit Boards) have revolutionized the electronics industry by enabling the design of lighter and more compact devices. According to a recent report by ResearchAndMarkets, the global flexible PCB market is projected to grow from $12.5 billion in 2023 to $19.5 billion by 2028, reflecting a compound annual growth rate (CAGR) of 9.1%. This significant increase underscores the growing demand for lightweight electronic solutions across industries ranging from consumer electronics to automotive applications.

The ability of flexible PCBs to drastically reduce size and weight comes from their thin, lightweight materials, which can be easily bent and shaped to fit complex designs. In modern electronic devices, where space is premium, flexible PCBs can lead to a 50% reduction in weight compared to traditional rigid PCBs. For example, in smartphones, the integration of flexible PCBs allows manufacturers to create slimmer designs without sacrificing performance. Additionally, these boards facilitate innovative form factors, enabling new features such as foldable screens and wearable technology that further emphasize portability and user convenience. The shift to flexible PCB technology not only enhances product aesthetics but also optimizes manufacturing processes and scalability in electronic production.

This chart illustrates the various benefits of flexible PCB boards in modern electronics, focusing on how they contribute to weight and size reduction, cost efficiency, design flexibility, and ease of integration. The percentages indicate the significant advantages flexible PCBs offer compared to traditional rigid PCBs in contemporary electronic designs.

Future Trends: Innovations and Challenges in Flexible PCB Technology for IoT Devices

The rapid evolution of the Internet of Things (IoT) has necessitated innovations in various technological components, with flexible printed circuit boards (PCBs) emerging as a pivotal player. These versatile boards are designed to adapt to the compact and intricate demands of modern IoT devices. Unlike traditional rigid PCBs, flexible PCBs enable lighter, thinner, and more complex designs, paving the way for innovative applications in wearable technology, smart home devices, and automotive electronics. Their ability to conform to different shapes not only enhances aesthetics but also optimizes space within devices, allowing for greater functionality.

Despite the numerous benefits of flexible PCBs, such as increased durability and improved performance, challenges persist in their adoption. One major hurdle is the complexity of manufacturing processes, which often require specialized equipment and techniques. Additionally, ensuring reliability and quality control remains a concern, as the flexibility can lead to issues like material fatigue over time. As the industry continues to explore advancements in materials and production methods, addressing these challenges will be crucial for realizing the full potential of flexible PCB technology in future IoT applications.

Related Posts

-

Exploring Unique Alternatives to Flexible PCB Board Solutions

-

Digital Insights and Tips for Optimizing Your Flexible Printed Circuit Design Process

-

Benefits of Enhanced Durability in Circuit Board Manufacturing for Electronics

-

Solutions for Streamlined Best Circuit Board Assembly: Achieving Excellence in Production

-

How to Design and Manufacture a High-Quality Printed Circuit Board from Scratch

-

Exploring Innovative Alternatives in PCB Electronics for Modern Applications