Top 10 Benefits of Printed Circuit Board Assembly for Your Projects?

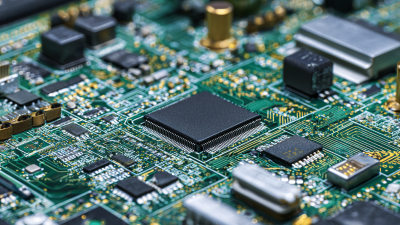

In the rapidly evolving world of technology, printed circuit board assembly plays a crucial role. Industry expert Dr. Emily Thompson states, “Effective PCB assembly can transform your project’s potential.” This highlights the growing importance of PCB assembly in diverse applications.

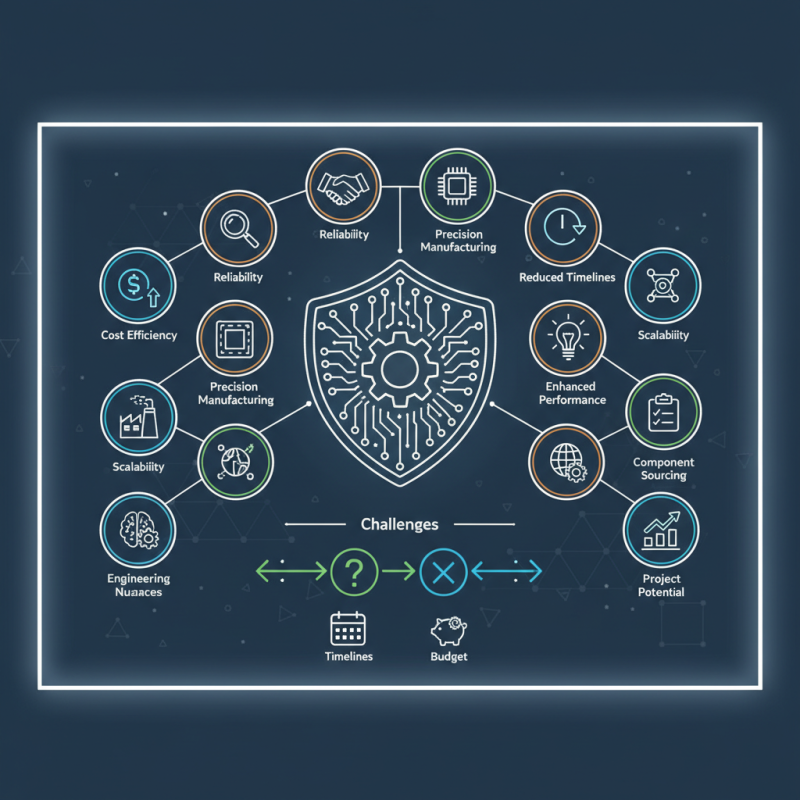

The benefits of printed circuit board assembly are numerous. From cost efficiency to reliability, each advantage builds a strong case for its use. For instance, precision in manufacturing reduces errors, ensuring high-quality outcomes. However, it’s essential to recognize that not all assembly processes are the same. Some projects might face unexpected challenges, such as component sourcing. These hurdles can impact timelines and budget considerations.

A well-executed printed circuit board assembly can significantly enhance performance. Yet, it's vital to remain mindful of the nuances involved. As projects scale, the complexity of assembly increases. Balancing quality control with efficiency remains a key reflection point for many engineers. Embracing these factors is crucial for a successful assembly experience.

Overview of Printed Circuit Board Assembly (PCBA)

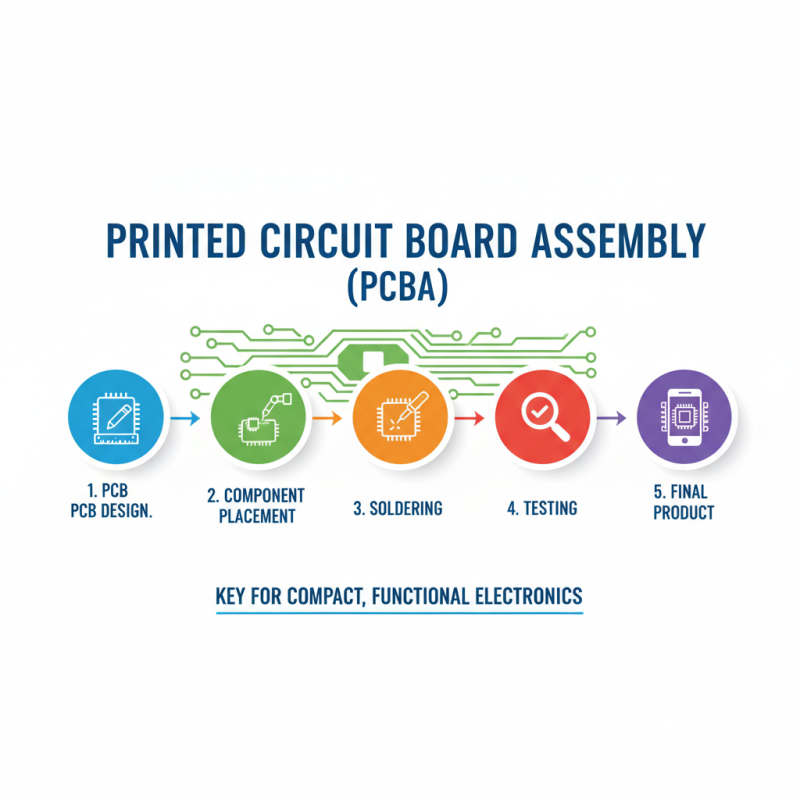

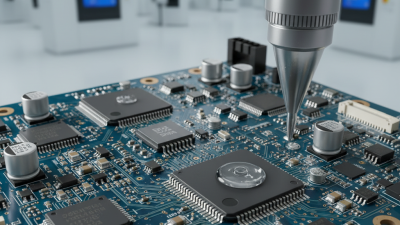

Printed Circuit Board Assembly (PCBA) is crucial for creating electronic devices. It combines multiple components into a single board, allowing for compact designs. This assembly process involves several steps, including PCB design, component placement, soldering, and testing. Each step is vital for ensuring quality and functionality.

When considering PCBA for your projects, pay attention to the design. A well-planned layout can reduce assembly errors and enhance performance. It's essential to select components wisely, as they affect reliability and cost. Always leave room for adjustments during design to accommodate unforeseen changes. Sometimes, designs come up short, leading to functionality issues. Make sure you conduct thorough testing of your assembled PCB.

**Tips:** Regular communication with your assembly team can prevent misunderstandings. Feedback loops help refine the assembly process. Document every revision for future reference to avoid repeating mistakes. Keeping track of errors and addressing them promptly can save time and money in the long run.

Cost Efficiency and Time Savings in PCB Assembly Projects

Cost efficiency and time savings are critical factors in printed circuit board (PCB) assembly projects. According to a recent industry report by IPC, companies that utilize automated PCB assembly techniques can see a reduction in assembly costs by up to 30%. This means more budget flexibility for additional project components. In fast-paced industries, every dollar counts.

Moreover, time savings can significantly impact overall project timelines. A survey from TechWatch indicated that companies reported a 40% decrease in lead time when switching to automated systems. Faster assembly translates to quicker product launches. It can provide a competitive edge in crowded markets. However, it’s essential to recognize potential pitfalls. Automation requires upfront investment and training. Each project’s complexity might dictate an entirely different approach.

Quality also deserves attention. While automation enhances efficiency, it can introduce challenges. The absence of human oversight may lead to undetected errors. A study highlighted that 5% of automated assemblies had quality issues. This reflects the balance needed in optimizing efficiency without sacrificing quality. Careful planning and continuous monitoring are necessary to mitigate such risks.

Top 10 Benefits of Printed Circuit Board Assembly for Your Projects

| Benefit | Description | Impact |

|---|---|---|

| Cost Efficiency | Reduction in manufacturing costs due to streamlined processes and bulk purchases of materials. | Lower project budget and higher profit margins. |

| Time Savings | Faster turnaround times as assembly processes are optimized. | Quicker project completion and faster time-to-market. |

| Quality Assurance | Rigorous testing and quality control leads to high reliability of PCBs. | Reduced failure rates and improved product durability. |

| Customization | Ability to design and produce boards tailored to specific project needs. | Greater flexibility in product design, meeting exact specifications. |

| Advanced Technology | Access to the latest PCB manufacturing technologies and materials. | Enhanced performance and functionality of electronic devices. |

| Scalability | Easy scaling of production to meet increasing demand. | Ability to grow business without concern for manufacturing limits. |

| Expert Support | Availability of expert advice and consultation during design and assembly. | Informed decision-making leading to better project outcomes. |

| Inventory Management | Efficient management of materials and components reduces wastage. | Lower costs and improved sustainability. |

| Regulatory Compliance | Manufacturing practices that adhere to industry standards and regulations. | Reduced legal risks and increased market acceptance. |

| Sustainability | Adoption of eco-friendly practices and materials in PCB production. | Positive impact on brand reputation and environmental responsibility. |

Improved Design Flexibility with Custom PCB Solutions

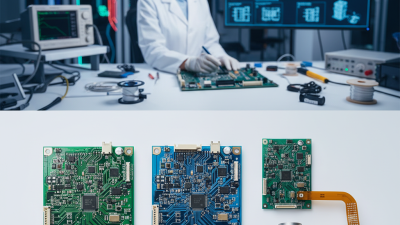

Printed Circuit Board (PCB) assembly plays a crucial role in modern electronics. One major benefit is improved design flexibility through custom PCB solutions. Designers can create unique layouts tailored to specific project needs. This flexibility allows for compact designs and optimized functionality.

Custom PCBs often lead to better performance. Tailored solutions can utilize advanced materials and techniques. However, some challenges may arise. Not every design will work flawlessly on the first attempt. Iteration is key to refining your PCB design.

Tips: When designing, think about component placement. Ensure that the thermal management is effective. Pay attention to trace width and spacing. These details matter. Testing prototypes can reveal issues early in the process. Don't shy away from making changes based on feedback. Learning from mistakes can lead to better results.

Enhanced Product Reliability through Quality PCB Assembly

Printed Circuit Board (PCB) assembly plays a crucial role in enhancing product reliability. High-quality PCB assembly reduces failure rates significantly. According to industry reports, reliable PCBs can improve device longevity by up to 30%. This reliability is driven by precise manufacturing practices and rigorous quality control processes that help prevent common issues such as solder joint failures and thermal fatigue.

Quality assurance in PCB assembly involves multiple testing phases. Automated optical inspection (AOI) is used to identify defects early in the production line. Research indicates that a 1% reduction in defects can increase overall product reliability by 15%. However, not all manufacturers utilize these advanced techniques. Some still rely on outdated processes that can lead to inconsistent quality and performance issues. This discrepancy highlights the importance of choosing manufacturers that prioritize quality in their assembly practices.

Moreover, investing in high-quality assembly can prevent costly recalls. A study found that recalls can cost companies over $10 million on average. This financial strain can be avoided by ensuring that PCBs meet stringent quality standards. The risk of failure is low when quality is prioritized, yet many projects still overlook this aspect. Keeping up with advancements in technology and process optimization can further enhance product reliability, ensuring a better user experience.

Top 10 Benefits of Printed Circuit Board Assembly for Your Projects

This chart illustrates the top benefits of using Printed Circuit Board (PCB) Assembly in projects, reflecting enhanced product reliability and efficiency.

Scalability Options for Growing Project Needs in PCB Manufacturing

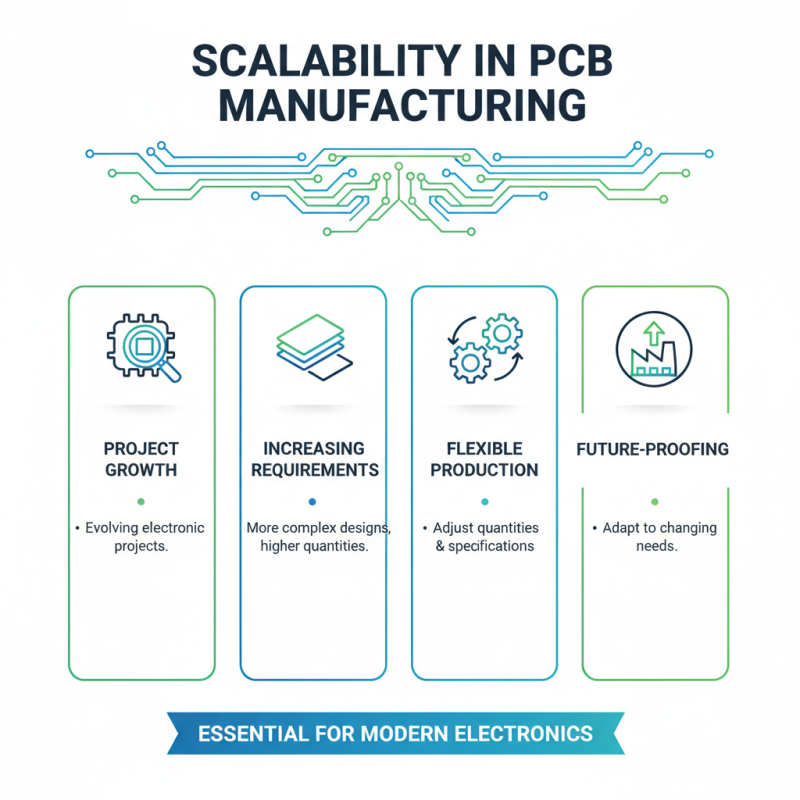

Printed circuit boards (PCBs) are essential for modern electronics. As projects grow, so do their requirements. Scalability in PCB manufacturing becomes crucial for meeting these evolving needs. Choosing scalable options allows for flexibility in production. You may need to adjust quantities or specifications as your project develops.

Consider your project’s lifespan. Some projects may start small but quickly expand. This is where scalable PCB assembly shines. You can begin with a limited run and increase as demand grows. This adaptability ensures you don't overproduce or underproduce. Adjust your orders based on real-time feedback. That way, you can minimize waste and costs.

Tips to consider: Always communicate your expectations with manufacturers. Share your projected growth to explore options. Research multiple companies offering scalable solutions. Assess their capacity to meet changing needs. Ultimately, being proactive about scalability can enhance project efficiency. Make thoughtful decisions as you refine your production process. Adaptability is key in today’s fast-paced market.

Related Posts

-

How to Choose the Best Circuit Board Maker for Your DIY Electronics Project

-

Top PCB Printing Trends to Watch in 2025 for Innovative Electronics

-

Leading the Way: Unmatched Export Strength of China’s Top PCB Circuit Boards

-

How to Optimize Printed Circuit Board Assembly for Better Performance?

-

Top PCB Printing Techniques That Improve Quality and Efficiency Guess Why

-

What is a PCB Board? Understanding Types, Functions, and Applications