Top 5 Benefits of Using Flexible Printed Circuit Boards in Modern Electronics

In recent years, the electronics industry has witnessed a significant shift towards the adoption of flexible printed circuit boards (FPCBs), driven by the increasing demand for compact and lightweight devices. According to a report by MarketsandMarkets, the flexible printed circuit board market is projected to grow from $23.7 billion in 2021 to $35.8 billion by 2026, reflecting a compound annual growth rate (CAGR) of 8.8%. This growth is fueled by the need for innovations in mobile devices, automotive electronics, and other high-tech applications that require space-saving solutions.

FPCBs offer unique advantages that differentiate them from traditional rigid circuit boards. Their flexibility enables designers to create smaller, more adaptable, and lightweight electronic products that can easily fit into confined spaces. Additionally, the ability to bend and twist FPCBs without compromising functionality expands design possibilities, encouraging creativity in product engineering. The remarkable performance characteristics of flexible printed circuit boards, such as improved reliability and durability, further enhance their appeal in modern electronic applications.

As electronic devices continue to advance, the integration of flexible printed circuit boards is becoming increasingly crucial. With their ability to support the miniaturization of components while maintaining optimal performance, FPCBs play a vital role in the future of electronics, setting the stage for the next generation of innovative products.

The Increasing Demand for Compact Electronics and FPCBs

The increasing demand for compact electronics has driven innovation in the design and manufacturing of electronic components. Flexible printed circuit boards (FPCBs) have emerged as a vital solution, catering to this trend by allowing designers to optimize space without compromising functionality. As devices become smaller and more intricate, FPCBs offer a unique advantage—they can be bent, folded, and contoured to fit within the tiniest enclosures, enabling the development of sleeker and more portable gadgets.

Moreover, the lightweight nature of FPCBs contributes to the overall reduction in the weight of electronics. This is increasingly important in sectors like wearable technology and mobile devices, where both aesthetics and functionality play a crucial role in consumer preferences. As manufacturers strive to meet the ever-evolving demands for miniaturized products, the integration of FPCBs becomes essential for enhancing performance while maintaining a reduced footprint. With their capability to support multiple layers and complex designs, FPCBs not only comply with compact design requirements but also deliver high reliability and durability in modern electronics.

Top 5 Benefits of Using Flexible Printed Circuit Boards in Modern Electronics

| Benefit | Description | Impact on Electronics |

|---|---|---|

| Space Efficiency | FPCBs are thinner and lighter than traditional rigid PCBs, allowing for more compact designs. | Enables smaller devices, increasing portability and convenience for users. |

| Flexibility | These boards can bend and fold without damaging the circuitry, adapting to unique design requirements. | Facilitates innovative product designs in wearables, medical devices, and more. |

| Reduced Weight | FPCBs contribute to reducing the overall weight of electronic products. | Critical for mobile and aerospace industries where weight is a vital consideration. |

| Improved Reliability | They are less susceptible to damage from vibrations and impacts due to their flexibility. | Enhances durability and longevity of devices, especially in challenging environments. |

| Design Versatility | Allows for more intricate circuit designs and layouts compared to rigid boards. | Promotes innovation and creativity in product development, leading to more advanced features. |

Cost-Effectiveness: Reducing Production and Material Costs with FPCBs

Flexible Printed Circuit Boards (FPCBs) have become pivotal in modern electronics, offering a myriad of advantages, particularly in terms of cost-effectiveness. By utilizing FPCBs, businesses can significantly reduce both production and material costs. The lightweight and flexible nature of FPCBs allows for compact designs, minimizing the need for bulky components and extensive wiring. This not only lowers material expenses but also streamlines the assembly process, resulting in reduced labor costs and shorter production times.

When considering the implementation of FPCBs, here are a few tips to maximize their cost-saving benefits. First, assess whether your product design can truly benefit from flexibility; designs requiring intricate routing can greatly reduce waste and material costs. Second, collaborate closely with PCB manufacturers to optimize the layout and materials used, which can lead to even greater savings. Lastly, consider how the longevity and durability of FPCBs can contribute to lower maintenance and replacement costs in the long run.

Adopting FPCBs is a strategic move that can enhance not only the efficiency of production but also the overall cost management of electronic devices. By leveraging their inherent advantages, companies can stay competitive in a market that increasingly demands both quality and economy.

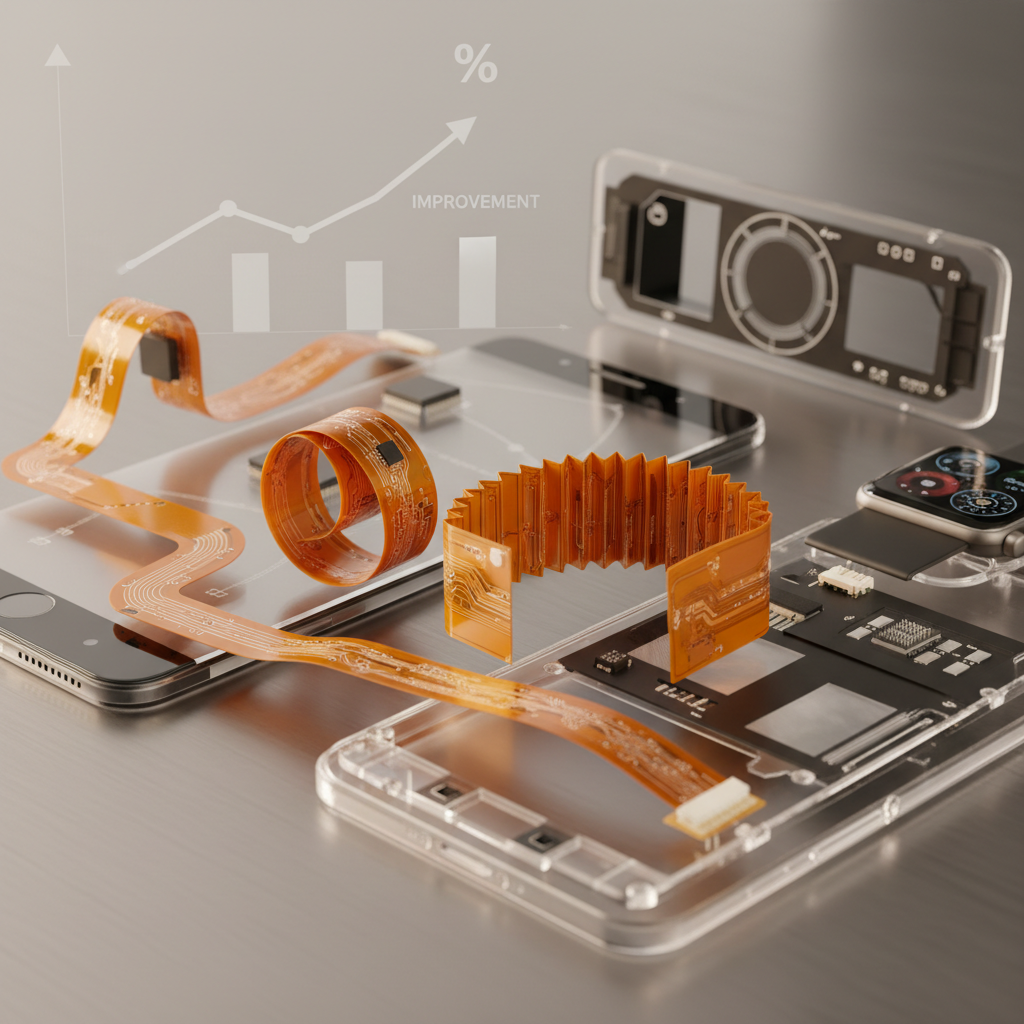

Enhanced Design Flexibility: Tailoring Circuit Layouts for Modern Devices

Flexible printed circuit boards (FPCBs) are revolutionizing modern electronics by offering enhanced design flexibility, which is increasingly crucial in today’s fast-paced technology landscape. As devices become smaller and more complex, the ability to tailor circuit layouts is essential. FPCBs allow for intricate designs that can easily conform to unique shapes and sizes, enabling manufacturers to optimize product performance while maximizing space efficiency. According to industry reports, the global automotive PCB market size is projected to reach approximately USD 18.14 billion by 2034, reflecting the increasing demand for adaptable and innovative circuit solutions.

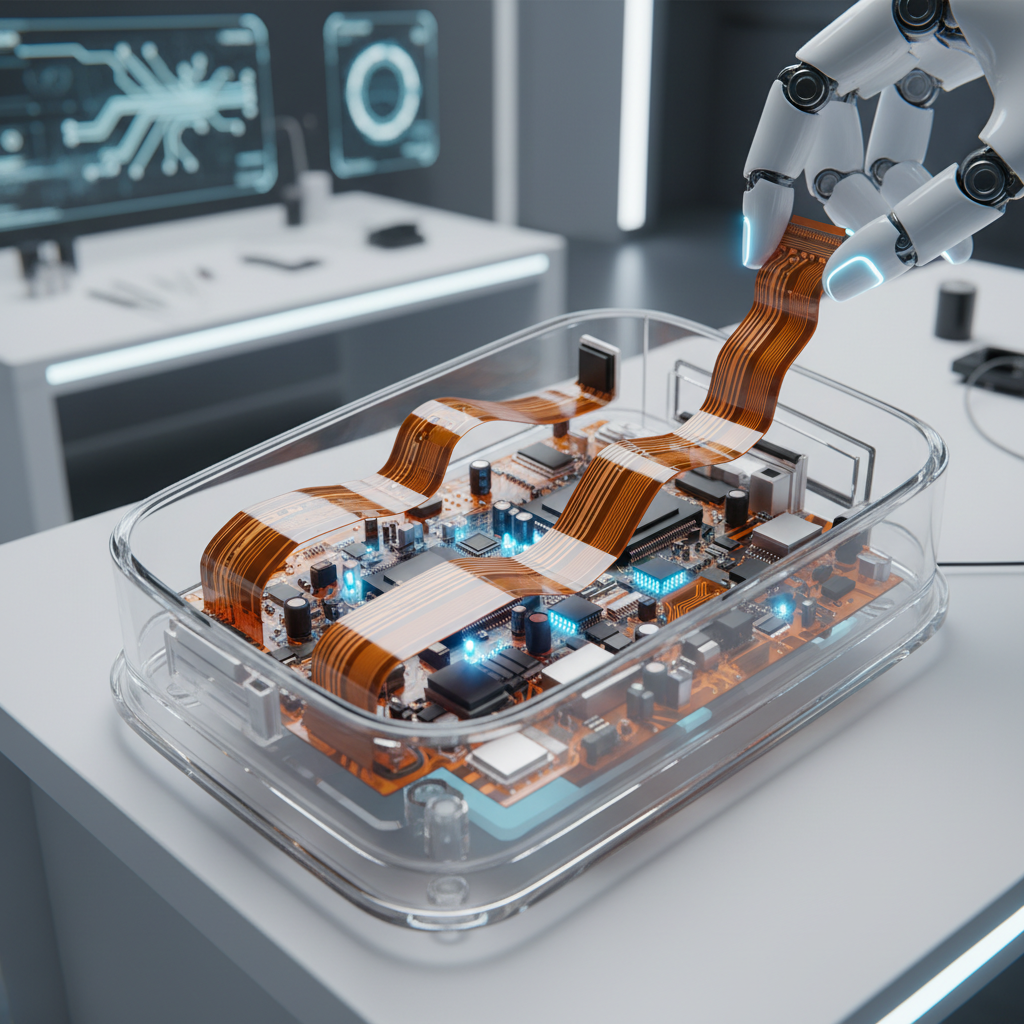

Moreover, the integration of AI-driven design optimization is transforming how engineers create FPCBs. This cutting-edge technology not only streamlines the design process but also enhances performance by reducing errors and improving layout efficiency. The recent innovation in flexible materials further supports this trend, allowing for circuits that can withstand bending and flexing without compromising functionality. As we move towards an era characterized by wearable technology and advanced electronic devices, the role of FPCBs in creating compact, high-performance designs will only continue to grow, paving the way for future advancements in the electronics field.

Top 5 Benefits of Using Flexible Printed Circuit Boards

Improved Reliability: The Impact of FPCBs on Device Longevity

Flexible Printed Circuit Boards (FPCBs) have

revolutionized modern electronics by offering enhanced reliability,

which significantly contributes to device longevity. According to industry reports, FPCBs can

improve fatigue resistance by up to 50%

compared to traditional rigid boards. This increased durability is essential in applications

where devices experience constant movement, such as in smartphones, wearables, and automotive electronics.

The flexibility of these circuits allows them to adapt to various shapes and sizes, reducing the

risk of mechanical failures caused by vibration and bending.

Moreover, the use of FPCBs is linked to a lower rate of thermal cycling failures,

with studies indicating a reduction in failure rates by as much as 30% in harsh

environments. This is particularly critical for devices operating in extreme temperatures, where

the thermal expansion of materials can lead to cracks and other forms of degradation. By minimizing

these risks, manufacturers can enhance the longevity of their products, resulting in reduced warranty

claims and improved customer satisfaction. Embracing FPCBs not only leads to more reliable devices

but also contributes to overall cost savings in production and maintenance.

Lightweight Solutions: How FPCBs Contribute to Portable Electronics Trends

Flexible Printed Circuit Boards (FPCBs) have become a pivotal component in the evolution of portable electronics, significantly contributing to trends in lightweight design. Their ability to bend and twist allows designers to create compact and ergonomic devices that can fit seamlessly into various applications. This flexibility is particularly advantageous for smartphones, wearables, and medical devices, where space is at a premium and user comfort is paramount. By reducing the weight of electronic assemblies, FPCBs enhance the overall portability of devices, making them more appealing to tech-savvy consumers seeking convenience and efficiency.

Moreover, the lightweight nature of FPCBs does not compromise their performance. In fact, they enable better thermal management and resistance to vibrations, which are essential for the durability of portable electronics. As manufacturers strive to develop sleeker and more efficient products, FPCBs offer a robust solution that supports advanced functionalities while minimizing weight. This balance between form and function is increasingly important in a market that demands innovative designs without sacrificing quality, propelling the industry towards greater advancements in portable technology.

Related Posts

-

The Definitive Handbook to Finding the Best Flexible Printed Circuit Board for Your Needs

-

Exploring Unique Features and Applications of the Best Electronic Board Alternatives for Global Buyers

-

Benefits of Enhanced Durability in Circuit Board Manufacturing for Electronics

-

Solutions for Streamlined Best Circuit Board Assembly: Achieving Excellence in Production

-

How to Choose the Right Flexible Circuit Board for Your Electronic Project Based on Industry Trends and Data

-

2025 Top 5 Circuit Board Assembly Trends You Can't Afford to Miss