Top 5 Best Circuit Board Manufacturing Techniques Explained?

In the ever-evolving world of circuit board manufacturing, innovation plays a critical role. Experts emphasize the importance of understanding various techniques that can enhance production quality and efficiency. John Smith, a well-respected figure in the circuit board industry, once stated, "The right manufacturing technique can significantly reduce costs while improving reliability."

Many techniques exist, but not all are created equal. Each method has its own strengths and weaknesses. For instance, traditional methods may provide stability but lack the agility of modern processes. On the other hand, newer techniques could risk inconsistent quality if not implemented properly. This balance is vital for any manufacturer aiming for success.

Circuit board manufacturing requires constant reflection and adaptation. Making informed choices is essential. Evaluating the pros and cons of each technique helps prevent costly mistakes. In this article, we delve into the top five manufacturing techniques that can elevate your production capabilities and drive your success.

Overview of Circuit Board Manufacturing Techniques

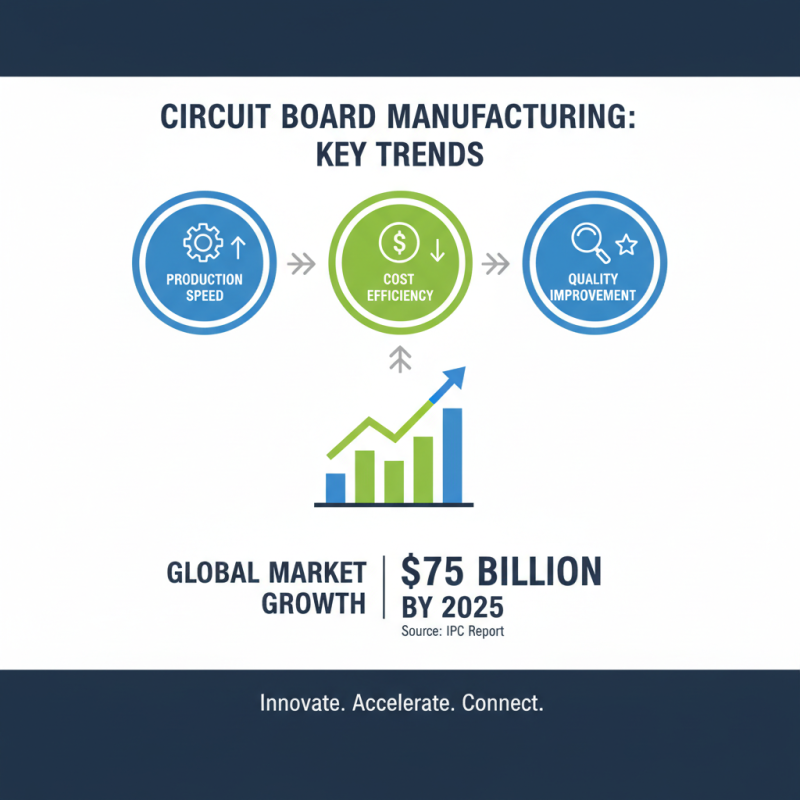

In the world of electronics, circuit board manufacturing techniques play a crucial role. Various methods influence production speed, cost, and quality. According to a report by IPC, the global circuit board market is projected to reach $75 billion by 2025. This rapid growth emphasizes the need for efficient manufacturing processes.

One common method is subtractive manufacturing. This involves removing copper from a substrate to create the desired circuit pattern. While effective, it often results in material waste. Studies indicate that around 50% of the material can be lost during the process. Companies face the challenge of balancing quality with environmental concerns.

Another approach is additive manufacturing, which builds circuits layer by layer. This method reduces waste but can be complex and costly. Some manufacturers report that setup times can be significantly longer compared to traditional methods. As the industry evolves, refining these techniques remains essential. The quest for better efficiencies continues, paralleling the demand for high-performance electronics.

PCB Design and Layout Fundamentals

When designing and laying out PCBs, attention to detail is crucial. Proper layout enhances functionality and performance. Start with a clear schematic to guide your design. Don’t forget to consider the size and shape of your circuit board early in the process. Amateur mistakes often arise from hurried measurements or overlooked spacing.

Tips: Always double-check dimensions. Use grid setup tools to ensure alignment. Minor errors can lead to significant issues later on.

Routing traces requires careful planning. Keep traces as short as possible to reduce resistance. Pay attention to capacitor and resistor placement as they can affect signal integrity. Avoid running traces parallel to one another over long distances, as this can create interference.

Tips: Utilize vias wisely. Too many can weaken the board structure. Focus on creating a balanced layout, as an uneven design can cause manufacturing and handling problems.

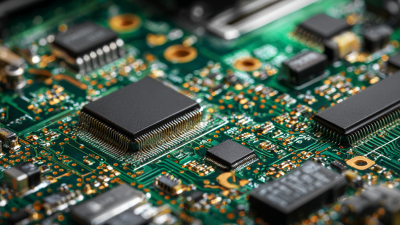

Substrate Materials and Their Impact on Performance

In circuit board manufacturing, substrate materials play a crucial role in overall performance. The choice of material impacts conductivity, thermal management, and mechanical strength. Common substrates like FR-4, polyimide, and ceramic each have distinct characteristics. For instance, FR-4 is widely popular for its balance between cost and performance. It operates efficiently up to 130°C and provides good electrical insulation. However, its limitations in high-frequency applications raise questions about its appropriateness for advanced electronics.

Ceramic substrates are used in high-performance applications. They excel in thermal management and offer better dielectric properties compared to FR-4. Studies show that ceramic substrates can withstand temperatures exceeding 200°C, making them ideal for high-power applications. However, they are more expensive and difficult to fabricate. These factors must be weighed carefully.

Tip: Consider your application’s demands. If high temperatures are expected, lean toward ceramic materials. In contrast, for standard applications, FR-4 might suffice.

Polyimide substrates offer flexibility and a wide temperature range, but they have lower thermal conductivity. Their use in flexible circuits is appealing, yet the challenge lies in their mechanical stability. Sometimes, the less conventional choices can yield surprising results. Be open to experimenting with different materials.

Fabrication Processes: From Printing to Etching

The fabrication of circuit boards is a complex process that involves various techniques. Among the core methods are printing, etching, and plating. Each of these steps plays a crucial role in creating reliable electronic circuits. In 2022, the global PCB market reached approximately $74 billion, highlighting the growing demand for advanced manufacturing processes.

Printing often involves using inks specifically designed for conductive pathways. These inks must adhere well to the substrate. A report from IPC estimates that printed circuits will witness a growth rate of 4.5% annually. However, challenges persist with the consistency of print quality. Variability can lead to weak connections or shorts between circuits.

Etching is another vital technique. It is used to remove unwanted copper from the surface layer. Chemical etching solutions must be carefully managed. Reports indicate that about 30% of etching processes result in defects. This can compromise the integrity of the circuit. Furthermore, laser etching is gaining traction, but it requires costly equipment that not all manufacturers can afford. Balancing cost and quality remains a pressing issue.

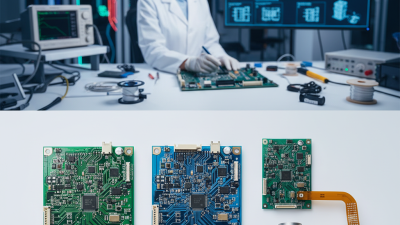

Assembly Techniques: Soldering and Component Placement

Soldering is a crucial part of circuit board assembly. It involves using heat to melt solder. This creates a bond between components and the board. Two common soldering techniques are through-hole and surface mount soldering. Each has its own characteristics.

Through-hole soldering is often considered traditional. It requires drilling holes into the circuit board. Components are inserted and then soldered onto the opposite side. This method is reliable but can be time-consuming. Surface mount soldering, however, places components directly on the board’s surface. It allows for smaller components and higher density. Yet, it can be tricky for beginners.

Component placement is equally important. Accurate placement affects the performance of the circuit. Misalignment can lead to circuit failure. Automated placement machines help improve precision. However, human error remains a risk. Even professionals can make mistakes in alignment. This highlights the need for careful checks in the process. Without attention, costly errors may occur.

Top 5 Circuit Board Manufacturing Techniques

This chart illustrates the popularity of various circuit board manufacturing techniques based on industry usage. The data represents the percentage of usage for each technique in 2023.

Conclusion

Circuit board manufacturing is a complex process that involves various techniques to ensure optimal performance and reliability. The article provides an overview of these methods, starting with PCB design and layout fundamentals, which lay the groundwork for efficient circuit functionality. The choice of substrate materials is also critical as they significantly influence the board's performance characteristics.

Fabrication processes are detailed, highlighting steps from printing to etching that create the intricate patterns necessary for electronic circuits. Additionally, assembly techniques such as soldering and component placement are examined to ensure that components are securely integrated into the boards. Finally, the article emphasizes the importance of testing and quality assurance in PCB manufacturing to guarantee that the finished products meet stringent standards before deployment. This comprehensive exploration of circuit board manufacturing techniques is essential for those looking to understand the intricacies of producing high-quality PCBs.

Related Posts

-

Innovative Uses in Aerospace and Challenges in Best Circuit Board Fabrication

-

How to Choose the Best Circuit Board Maker for Your DIY Electronics Project

-

Innovative Circuit Board Assembly Techniques Shaping the Future of Electronics

-

Exploring Innovative Alternatives in PCB Electronics for Modern Applications

-

10 Smart Tips for Mastering PCB Circuit Design in the Digital Era

-

What is a PCB Board? Understanding Types, Functions, and Applications