How to Choose the Best Circuit Board Maker for Your DIY Electronics Project

When embarking on a DIY electronics project, one of the most critical decisions you'll face is choosing the right circuit board maker. The quality of the circuit boards you use can significantly impact the functionality and longevity of your final product. With a plethora of options available in the market, it can be overwhelming to sift through them and identify which maker aligns best with your specific needs. This guide aims to simplify that process by providing insights into what characteristics to look for in a circuit board maker, from manufacturing capabilities and material quality to cost-effectiveness and customer support.

Understanding the nuances of different circuit board makers can be the key to a successful project. Whether you are a seasoned engineer or a DIY enthusiast, grasping the essential factors—such as turnaround times, design specifications, and technological advances—will help you make an informed choice. In this article, we will explore the top 10 circuit board makers, evaluating their strengths and weaknesses to help you find the best fit for your next electronics endeavor. By the end of this guide, you will be equipped with the knowledge necessary to select a circuit board maker that meets both your technical requirements and budget constraints, paving the way for successful and innovative projects.

Factors to Consider When Selecting a Circuit Board Maker for DIY Projects

When selecting a circuit board maker for your DIY electronics project, there are several crucial factors to consider. First and foremost, assess the manufacturer's capabilities regarding the type of PCB you need. Different projects have varying specifications, such as the number of layers, types of materials, and size constraints. Identifying a manufacturer that specializes in your specific requirements can significantly enhance the efficiency and quality of your prototype.

Another important aspect to evaluate is the lead time and production speed. For DIY enthusiasts working on prototyping runs, timely delivery can be critical. Look for makers that provide transparent timelines and reliable service, as delays can hinder your development process. Additionally, consider the cost-effectiveness of their services; balancing quality with your budget will ensure that you get the best value without compromising your project's integrity. By focusing on these factors, you can make an informed decision that aligns with your project goals and enhances your overall experience with PCB fabrication.

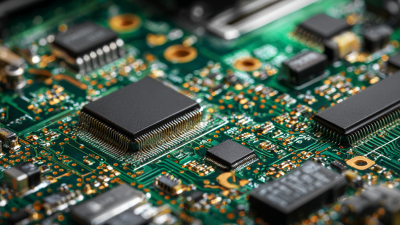

Understanding the Importance of PCB Material Quality in Electronics Manufacturing

The miniaturization of printed circuit boards (PCBs) is driving significant transformations in the electronics industry, enhancing both efficiency and reliability. As the demand for smaller, more powerful, and feature-rich devices rises, the quality of PCB materials has become increasingly crucial. Recent market analyses suggest that the demand for silicon chips will continue to surge, reflecting a projected growth in the electronics chemicals and materials sector until 2032. This growth is particularly vital for applications in implantable devices, wearables, and flexible displays.

When selecting a PCB maker, it's essential to prioritize the quality of materials used. High-quality substrates can significantly influence the performance, durability, and reliability of your electronics.

Tips:

- Always inquire about the PCB manufacturer's sourcing of raw materials and their adherence to industry standards.

- Look for makers who employ advanced manufacturing technologies to ensure consistent quality and innovation in PCB design.

The evolving landscape of the SMT industry indicates a focus on high multi-layer boards, indicating a shift towards more intricate designs that cater to the demand for enhanced functionalities in a connected world.

Evaluating Turnaround Time: How Speed Affects Your DIY Projects

When embarking on a DIY electronics project, one crucial factor to consider is the turnaround time provided by circuit board makers. Fast processing speeds matter significantly in ensuring that your project stays on track. If your circuit boards take too long to manufacture, it can delay your experimentation and final product. In a world where agility is vital—evidenced by the increasing impact of technologies like artificial intelligence on productivity—having quick access to essential components can make or break your project timeline.

**Tips for Evaluating Turnaround Time:**

1. **Set Clear Deadlines:** Before choosing a circuit board maker, establish a timeline for your project. Discuss the urgency of your needs with potential manufacturers to gauge their capability to meet your deadlines.

2. **Review Customer Feedback:** Check for reviews or testimonials focusing specifically on the turnaround time. Insights from previous customers can give you a better understanding of the reliability and speed of service.

3. **Request Samples:** If time allows, request samples from a few makers to compare their processing speeds. This hands-on approach can help you make an informed decision based on your project requirements.

Choosing the right circuit board maker based on turnaround time ensures that you remain competitive and efficient in your DIY endeavors, ultimately leading to successful and timely project completions.

Turnaround Time for Circuit Board Makers

Assessing the Cost-Effectiveness of Different Circuit Board Makers

When embarking on a DIY electronics project, choosing the right circuit board maker is crucial for balancing quality and cost-effectiveness. A recent industry report indicated that the average cost of manufacturing a printed circuit board (PCB) can range from $200 to $2,000, depending on volume, materials, and complexity. For small-scale projects, opting for a maker that supports low-volume production can significantly reduce costs. Companies like PCBWay and JLCPCB have emerged as leaders in the market, offering competitive pricing structures with options for expedited services that can meet tight deadlines without breaking the bank.

Moreover, the trade-off between price and quality is a vital consideration. According to a survey by PCBReview, over 60% of designers prefer makers that offer at least a one-year warranty on their products, highlighting the importance of reliability alongside affordability. Additionally, onboard capabilities such as advanced testing and prototyping services can justify a higher price point, ensuring the final product meets expected performance standards. Choosing a maker that excels in both cost-effectiveness and quality assurance measures can ultimately lead to a more successful and satisfying DIY electronics experience.

The Role of Customer Support and Communication in Choosing PCB Suppliers

When selecting a PCB supplier for your DIY electronics project, customer support and communication should be at the forefront of your decision-making process. Effective communication can streamline the design process, allowing you to clarify specifications and avoid costly mistakes. A PCB maker that provides responsive customer service can help answer any technical questions and support troubleshooting, enhancing your project experience and ensuring timely delivery of your boards.

Furthermore, robust customer support often reflects a supplier's commitment to quality and customer satisfaction. When potential issues arise during production or shipping, a responsive support team can provide updates and solutions, minimizing disruptions to your project timeline. It's essential to consider how a supplier engages with its clients; reliable communication channels can make the difference between a smooth project and a frustrating experience. Ultimately, the right PCB maker should not only meet your technical needs but also foster a collaborative relationship that enhances the overall success of your electronics project.

How to Choose the Best Circuit Board Maker for Your DIY Electronics Project - The Role of Customer Support and Communication in Choosing PCB Suppliers

| Criteria | Rating (1-5) | Comments |

|---|---|---|

| Quality of Boards | 4 | Consistently good quality, minimal defects. |

| Customer Support | 5 | Responsive and helpful with inquiries. |

| Communication | 4 | Clear updates throughout the process. |

| Turnaround Time | 3 | Generally on time but sometimes delays. |

| Pricing | 4 | Competitive pricing for quality offered. |

| User Reviews | 5 | Mostly positive feedback from users. |

Related Posts

-

Benefits of Enhanced Durability in Circuit Board Manufacturing for Electronics

-

How to Design and Manufacture a High-Quality Printed Circuit Board from Scratch

-

Innovative Uses in Aerospace and Challenges in Best Circuit Board Fabrication

-

Leading the Way: Unmatched Export Strength of China’s Top PCB Circuit Boards

-

Solutions for Streamlined Best Circuit Board Assembly: Achieving Excellence in Production

-

Innovative Circuit Board Assembly Techniques Shaping the Future of Electronics