How to Choose the Right Metal Core PCB for Your Project in 2025

As the demand for efficient thermal management in electronic devices continues to rise, selecting the right metal core PCB becomes increasingly crucial for engineers and designers in 2025. According to Dr. Emily Chen, a leading expert in the field of printed circuit board technology, "The choice of a metal core PCB can significantly impact both the performance and longevity of your product." This statement underscores the importance of understanding the specific requirements of your project, such as heat dissipation and mechanical stability, when considering various types of PCBs.

In a landscape where innovation is a key driver, the variety of metal core PCBs available can be overwhelming. Factors such as material composition, thickness, and design complexity must all be taken into account to ensure that the chosen PCB not only meets the technical specifications but also fits within budget constraints. As technology advances, metal core PCBs are becoming more sophisticated, offering enhanced thermal management capabilities that can lead to more reliable and efficient devices. By carefully evaluating these factors and leveraging expert insights, you can make informed decisions that will propel your project toward success.

In an era where performance is paramount, understanding how to navigate the options presented by metal core PCBs will be essential for any forward-thinking engineer.

Understanding Metal Core PCBs: Definition and Characteristics

Metal Core PCBs (MCPCBs) are a specialized type of printed circuit board designed to handle higher thermal loads than traditional PCBs. They are characterized by a metallic base, typically aluminum or copper, which effectively dissipates heat generated by high-power components. This feature makes them ideal for applications in LED lighting, power electronics, and automotive systems, where heat management is crucial for reliability and performance.

One of the primary characteristics of metal core PCBs is their ability to maintain a lower temperature threshold during operation, thus preventing performance degradation over time. The thermal conductivity of the metal substrate helps spread heat away from sensitive components, reducing the risk of thermal-related failures. Additionally, MCPCBs can support thicker copper traces compared to regular PCBs, further enhancing their capacity to conduct electricity efficiently while minimizing voltage drop. As electronic devices continue to evolve, understanding the unique properties of metal core PCBs will be essential for engineers to design effective and sustainable solutions for their projects in the coming years.

Understanding Metal Core PCB Performance Characteristics in 2025

Key Factors to Consider When Choosing a Metal Core PCB

When selecting the right metal core PCB (MCPCB) for your project, several key factors should be taken into consideration. First and foremost, the thermal conductivity of the metal core material is crucial. MCPCBs are specifically designed to manage heat better than traditional PCBs, making them suitable for applications with high thermal demands. Evaluating the thermal conductivity ensures that the PCB can effectively dissipate heat, thus preventing components from overheating and enhancing the performance and lifespan of the final product.

Another vital factor to consider is the dielectric layer's properties. The thickness and material of the dielectric layer play significant roles in the board's overall performance. A thicker dielectric can provide better insulation and improved thermal management, which is essential in high-power applications. Additionally, understanding the manufacturing tolerances and capabilities can help ensure that the MCPCB meets the required specifications for your project. Engaging with manufacturers early in the design phase allows for a better understanding of how various factors, like layer count and copper thickness, can impact both performance and cost efficiency.

Application Suitability: Identifying Your Project's Requirements

When selecting the right metal core PCB (MCPCB) for your project, understanding your specific application requirements is crucial. Different projects may demand different thermal management solutions, electrical properties, or structural integrity. Assessing the operational environment—such as temperature ranges, humidity levels, and potential mechanical stress—will guide you toward the appropriate material and design specifications to ensure reliability and performance.

**Tips:** Consider the heat dissipation needs of your project. If it involves high power output, choose an MCPCB with a higher thermal conductivity material to efficiently manage excess heat. Additionally, think about the longevity required for your application; some projects may benefit from enhanced durability features in the PCB design.

Another key factor is the complexity of your circuit design. More intricate designs may require multilayer options, while simpler applications may effectively perform with a single layer. Ensure to communicate specific electrical performance requirements, such as dielectric strength and thermal resistance, with your PCB manufacturer to avoid compatibility issues.

**Tips:** When defining your project’s requirements, make a checklist of essential features like size constraints, layer count, and any specific performance metrics needed, which will streamline the selection process. Moreover, early collaboration with your engineering team can prevent costly redesigns later in the development cycle.

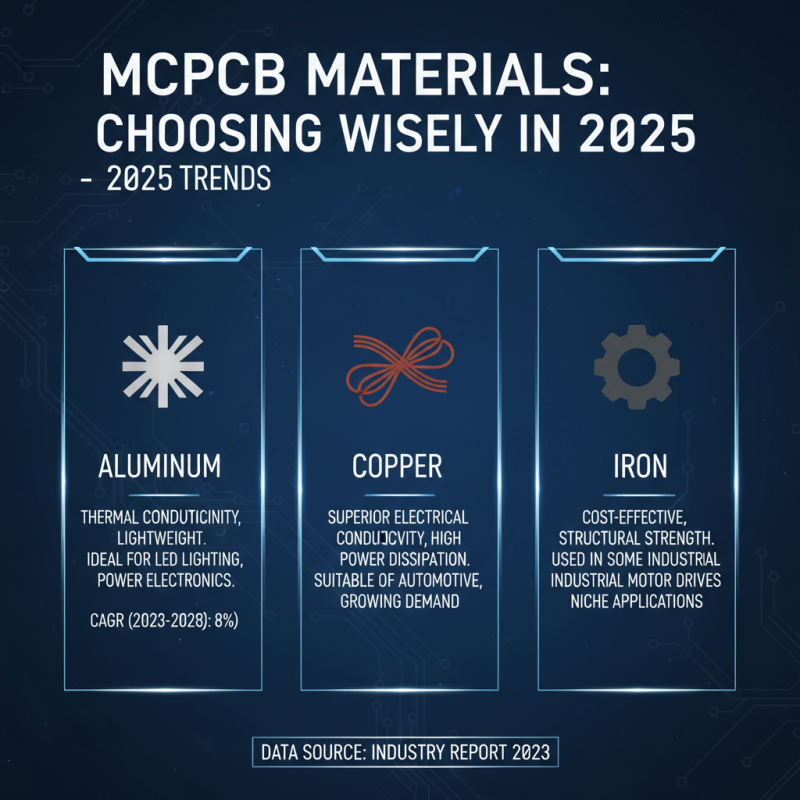

Comparing Common Metals Used in PCB Construction

When selecting the right metal core PCB (MCPCB) for your project in 2025, it is crucial to understand the metallic materials used in their construction. Currently, aluminum, copper, and iron are among the most commonly utilized metals in PCB manufacturing, each offering distinct advantages depending on the application requirements. For instance, aluminum is favored for its excellent thermal conductivity and lightweight properties, making it ideal for LED lighting and high-power electronic applications. According to a recent industry report, the aluminum segment is projected to witness a CAGR of 8% from 2023 to 2028, driven by increasing demand in various sectors.

Copper, while more expensive than aluminum, is renowned for its superior electrical conductivity, making it an optimal choice for high-frequency applications. Its high thermal performance is critical in ensuring efficient heat dissipation, which is especially important for power electronics. Industry analysis indicates that the adoption of copper-based MCPCBs is expected to grow significantly in sectors such as telecommunications and automotive, where reliability and efficiency are paramount. In contrast, iron core PCBs are generally used in less demanding applications due to their reduced conductivity and heavier weight, although they provide adequate performance for more basic electronic devices.

Ultimately, the choice of metal core not only influences the thermal and electrical performance of the PCB but also impacts cost and manufacturing complexity. For designers and engineers, weighing these factors against the project’s specific requirements will be vital for optimizing performance and efficiency in 2025 and beyond.

Cost vs. Performance: Making the Right Trade-Offs for Your Project

When selecting a metal core PCB for your project, one of the most critical considerations is the balance between cost and performance. Metal core PCBs (MCPCBs) offer improved thermal management and durability, making them ideal for high-power applications. However, they often come with a higher initial investment compared to traditional PCBs. To ensure that your project remains within budget while achieving optimal performance, it’s essential to assess your specific requirements. This involves identifying the thermal dissipation needs of your components and evaluating how much you can spend without compromising on reliability and efficiency.

In many cases, performance enhancements such as better heat dissipation and increased lifespan can justify the additional costs associated with MCPCBs. Nevertheless, it’s crucial to conduct a thorough analysis of your project’s goals. If your application demands only moderate performance, opting for a less expensive solution might be more appropriate. Conversely, if failure due to overheating could lead to significant costs or safety concerns, investing in a high-performance metal core PCB could be the right choice. Ultimately, understanding your project’s needs and aligning them with the appropriate PCB option will enable you to make informed trade-offs that meet both budgetary and performance criteria.

Related Posts

-

The Future of Aluminum PCB: Innovations Driving Sustainable Electronic Design

-

Solutions for Streamlined Best Circuit Board Assembly: Achieving Excellence in Production

-

Leading the Way: Unmatched Export Strength of China’s Top PCB Circuit Boards

-

Benefits of Enhanced Durability in Circuit Board Manufacturing for Electronics

-

Exploring Innovative Alternatives in PCB Electronics for Modern Applications

-

Exploring Unique Alternatives to Flexible PCB Board Solutions