How to Choose the Right Flexible Circuit Board for Your Electronic Project Based on Industry Trends and Data

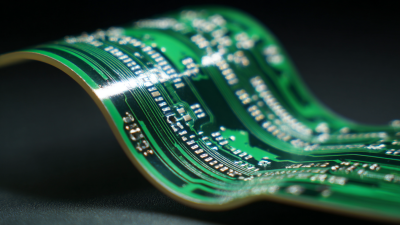

In the ever-evolving landscape of electronics, the importance of selecting the right flexible circuit board cannot be overstated. As devices become more compact and functionality increases, flexible circuit boards emerge as a pivotal element in modern electronic design. This introduction aims to guide engineers and project managers through the process of choosing the most suitable flexible circuit board, informed by current industry trends and data.

Flexible circuit boards offer unique advantages, such as lightweight design and adaptability to various shapes, making them ideal for applications ranging from consumer electronics to complex medical devices. However, with the rapid advancements in technology and manufacturing processes, the decision-making criteria for selecting a flexible circuit board have become more nuanced.

By analyzing recent trends and understanding how they influence the performance, reliability, and cost-effectiveness of flexible circuits, stakeholders can make informed choices that enhance their electronic projects. This article will delve into key factors to consider and provide insights into making the right selection amidst a landscape rich with options and innovations.

Understanding the Basics of Flexible Circuit Boards in Modern Electronics

Flexible circuit boards are becoming essential components in contemporary electronic designs due to their unique advantages over traditional rigid boards. These circuits utilize flexible substrates that can bend, twist, and conform to various shapes, allowing for innovative designs in compact spaces. As industries push the boundaries of technology, flexible circuit boards enable the integration of more functionality into smaller devices, which is particularly beneficial in sectors such as consumer electronics, medical devices, and automotive applications.

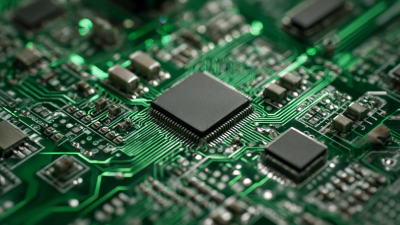

Understanding their construction is vital for leveraging the potential of flexible circuits. They typically consist of conductive traces made from materials like copper, layered on a flexible substrate such as polyimide or polyester. This construction not only provides electrical connections but also offers durability and resistance to stress, making them suitable for dynamic applications. Emerging trends indicate a growing demand for more complex circuit patterns and integration with advanced materials, further enhancing the performance and reliability of flexible circuit boards in the fast-evolving landscape of modern electronics.

Key Factors to Consider When Selecting Flexible Circuit Boards

When selecting the right flexible circuit board for your electronic project, several key factors must be considered to keep pace with current industry trends. One of the primary influences is the ongoing trend towards miniaturization in the electronics sector, which demands smaller, more efficient, and multifunctional devices. This shift necessitates the adaptation of flexible circuit boards that can be integrated into compact spaces while maintaining reliability and performance.

Another critical factor is material selection, as advancements in materials science can greatly enhance the capabilities of flexible circuits. The choice of dielectric materials, for example, affects both the flexibility and thermal management of the circuit boards. Additionally, it's essential to account for the specific application requirements and industry standards that may dictate certain design parameters. As the global printed circuit board market is projected to grow significantly in the coming years, aligning your project with these trends will ensure that the selected flexible circuit board optimally meets evolving technological demands.

How to Choose the Right Flexible Circuit Board for Your Electronic Project Based on Industry Trends and Data - Key Factors to Consider When Selecting Flexible Circuit Boards

| Key Factor | Description | Industry Trend | Data |

|---|---|---|---|

| Material Type | Choose the right flexible substrate material based on project requirements. | Increased demand for high-performance materials. | 65% preference for high-thermal performance materials. |

| Layer Count | Determine the number of layers based on complexity and design. | Trend towards multilayer designs in compact applications. | 40% growth in demand for 4-6 layer flexible circuits. |

| Production Method | Select between manual, semi-automated, or fully automated production methods. | Shift towards automation for efficiency and scalability. | 70% of manufacturers now prefer automated processes. |

| Thickness | Consider the overall thickness of the circuit for flexibility needs. | Trend towards thinner circuits for enhanced flexibility. | 85% of new designs prefer circuits under 0.5 mm. |

| Environmental Compliance | Ensure materials and processes adhere to environmental regulations. | Increasing regulations on electronics manufacturing sustainability. | 60% of companies report higher compliance costs. |

Latest Industry Trends Impacting Flexible Circuit Board Design

The flexible circuit board market is witnessing significant growth driven by evolving industry trends, particularly in sectors like automotive and consumer electronics. As the global automotive PCB market is projected to expand from $9.15 billion in 2023 to $15.1 billion by 2032, with a compound annual growth rate (CAGR) of 5.9%, it highlights the accelerating demand for advanced electronic solutions that incorporate flexible circuits. This trend underscores the need for innovative circuit designs that can meet the rigid performance standards within automotive applications, where reliability and compactness are paramount.

Adapting to these trends, manufacturers are increasingly focusing on developing flexible circuit boards that offer enhanced durability and tensile strength while remaining lightweight and cost-effective. The push towards electric vehicles and smart technologies further necessitates the integration of flexible circuitry, as these applications often require complex layouts to optimize space and performance.

Therefore, understanding market dynamics and aligning circuit board designs with these industry advancements is essential for engineers and designers working on electronic projects. This strategic approach will ensure compatibility with new technologies and will anticipate future market needs.

Analyzing Performance Data to Inform Your Material Choices

When selecting a flexible circuit board for your electronic project, analyzing performance data is crucial in informing your material choices. Performance data provides insights into the durability, thermal stability, and electrical conductivity of different materials, allowing designers to make informed decisions that align with project requirements. For instance, polyimide materials outperform others in high-temperature applications due to their excellent thermal resistance, making them ideal for industries like aerospace and automotive where heat management is critical.

Additionally, understanding the specific performance metrics related to bending and flexing capabilities can direct your selection process. Data on cycle life and fatigue resistance highlight how well a circuit board can withstand repeated movements without failure, which is essential for wearable devices or any product emphasizing mobility. By consulting up-to-date industry trends and leveraging empirical data, engineers can optimize the performance and longevity of their flexible circuit boards, ensuring that they meet both current challenges and future advancements in electronic design.

Best Practices for Integrating Flexible Circuit Boards into Your Projects

Integrating flexible circuit boards into electronic projects requires a deep understanding of both industry trends and practical applications. A recent report from the Flexible Electronics and Displays (FED) Association highlights that the flexible circuit board market is projected to reach $25 billion by 2026, fueled by advancements in consumer electronics and automotive applications. To successfully implement flexible circuits, designers should focus on selecting the right materials, understanding manufacturing processes, and incorporating reliability testing into their projects.

Practical application of knowledge in real-world settings is essential. As a quote goes, "To know is not enough; we must apply. Wishing is not enough; we must do." By engaging in hands-on projects, engineers can better comprehend the unique properties of flexible circuits, such as their bendability and lightweight characteristics which are crucial for modern applications. The best practice often involves iterative testing and refinement based on feedback from prototyping stages, allowing for optimal performance and integration into final products.

Incorporating industry-standard practices, such as IPC-A-600 for printed circuit boards, ensures adherence to reliability and quality benchmarks that are vital in today’s competitive landscape.

Related Posts

-

Understanding the Benefits and Applications of Flexible PCB Boards in Modern Electronics

-

Digital Insights and Tips for Optimizing Your Flexible Printed Circuit Design Process

-

Innovative Applications of Flexible PCB Boards in Modern Electronics

-

Unlocking Success: The Advantages of Advanced PCB Fabrication Techniques for Global Buyers

-

How to Design and Manufacture a High-Quality Printed Circuit Board from Scratch

-

Benefits of Enhanced Durability in Circuit Board Manufacturing for Electronics