Benefits of Enhanced Durability in Circuit Board Manufacturing for Electronics

In the rapidly evolving electronics industry, the durability of circuit boards has become a critical factor in determining the performance and lifespan of electronic devices. According to a report by IPC, the global market for printed circuit boards is anticipated to reach $82.27 billion by 2026, driven by the increasing demand for consumer electronics and automotive applications. Enhanced durability in circuit board manufacturing not only mitigates the risk of failures caused by environmental stressors but also improves the overall reliability of electronic products. Industry studies show that durable circuit boards can reduce maintenance costs by up to 30% and extend product lifecycles significantly. As manufacturers strive to meet these heightened demands, understanding the benefits of enhanced durability in circuit board design and production is essential for sustaining competitiveness in the market.

Understanding Enhanced Durability in Circuit Board Design and Manufacturing

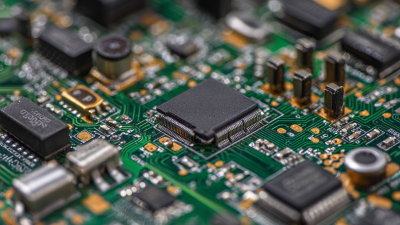

Enhanced durability in circuit board design and manufacturing is a crucial factor that significantly impacts the overall performance and lifespan of electronic devices. As electronic applications grow increasingly complex and demanding, circuit boards must withstand various environmental stressors, including temperature fluctuations, moisture, and mechanical stress. By incorporating advanced materials and design techniques, manufacturers can improve the resilience of circuit boards, ensuring they operate effectively in diverse conditions.

Enhanced durability in circuit board design and manufacturing is a crucial factor that significantly impacts the overall performance and lifespan of electronic devices. As electronic applications grow increasingly complex and demanding, circuit boards must withstand various environmental stressors, including temperature fluctuations, moisture, and mechanical stress. By incorporating advanced materials and design techniques, manufacturers can improve the resilience of circuit boards, ensuring they operate effectively in diverse conditions.

One major aspect of enhanced durability is the use of high-quality substrates and coatings that protect against corrosion and wear. These improvements not only extend the lifespan of the circuit boards but also enhance their functionality and reliability. For instance, adopting flexible printed circuit boards (PCBs) can offer greater durability by accommodating dynamic movements and vibrations common in electronic products. As a result, devices equipped with durable circuit boards tend to exhibit fewer failures and maintenance requirements, leading to increased customer satisfaction and reduced lifecycle costs.

Moreover, enhanced durability supports sustainability initiatives in electronics manufacturing. By reducing the frequency of component replacement and waste generation, manufacturers contribute to a more environmentally friendly production model. This focus on longevity and performance not only benefits end-users but also aligns with a growing demand for eco-conscious manufacturing practices in the electronics industry.

Key Materials and Techniques for Increasing Circuit Board Longevity

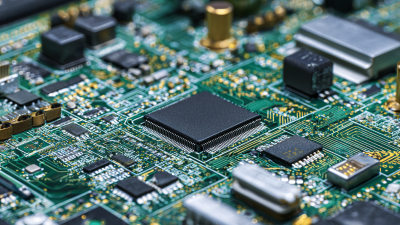

Enhancing the longevity of circuit boards is critical in meeting the ever-increasing demands of modern electronics. The utilization of advanced materials plays a pivotal role in extending the life of these vital components. For instance, the incorporation of high-performance substrates like polyimide and thermally stable epoxy has been shown to significantly withstand thermal cycling and mechanical stress. These materials not only improve thermal conductivity but also reduce the risk of delamination, making them ideal for high-reliability applications such as aerospace and automotive industries.

In addition to superior materials, innovative manufacturing techniques contribute to increased circuit board durability. Techniques like surface mount technology (SMT) and advanced soldering methods improve component adhesion and minimize solder joint fatigue. Moreover, conformal coatings offer an extra layer of protection against moisture, dust, and chemicals, enhancing the board's resistance to environmental factors. By integrating these materials and methods, manufacturers can create circuit boards that not only meet rigorous performance standards but also ensure reliable operation throughout their intended lifespan.

Impact of Enhanced Durability on Electronics Performance and Reliability

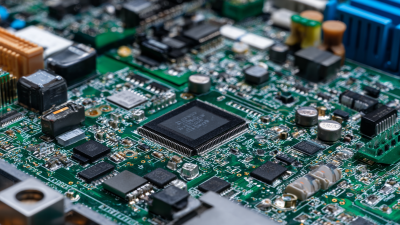

Enhanced durability in circuit board manufacturing significantly influences the performance and reliability of electronic devices. When circuit boards are built with improved materials and processes, they exhibit greater resistance to environmental stresses such as temperature fluctuations, humidity, and mechanical shock. This resilience not only extends the lifespan of the electronics but also ensures that they function optimally under varying conditions. As a result, manufacturers and consumers alike can benefit from reduced failure rates and maintenance costs, which are critical factors in both consumer and industrial applications.

Moreover, the impact of enhanced durability transcends mere longevity; it also translates into improved performance metrics. Durable circuit boards can support higher data transmission speeds and increased functionality without compromising on stability. This means that devices can execute more complex tasks and integrate advanced features, ultimately leading to a better user experience. In industries where reliability is paramount—such as aerospace, automotive, and medical devices—enhanced durability becomes a critical factor that determines not just performance but also safety and effectiveness in real-world applications.

Benefits of Enhanced Durability in Circuit Board Manufacturing for Electronics - Impact of Enhanced Durability on Electronics Performance and Reliability

| Feature | Description | Impact on Performance | Reliability Improvement |

|---|---|---|---|

| Material Quality | Use of high-grade materials that resist environmental stress. | Improves signal integrity and reduces noise. | Significantly extends the operational lifespan of the circuit board. |

| Thermal Management | Advanced designs that dissipate heat efficiently. | Enhances performance under high-load conditions. | Reduces the risk of thermal fatigue and failure. |

| Surface Finish | Use of durable surface coatings to prevent corrosion and wear. | Maintains clean connections for better electrical performance. | Enhances reliability by preventing surface degradation over time. |

| Mechanical Strength | Improved rigidity and flexibility in design to withstand physical stress. | Ensures consistent performance in mobile and rugged applications. | Decreases likelihood of board cracking or damage during use. |

| Moisture Resistance | Implementation of moisture-resistant coatings and sealants. | Protects sensitive electronic components from damage. | Boosts reliability in humid or wet environments. |

Cost-Benefit Analysis: Investing in Durable Circuit Board Solutions

Investing in durable circuit board solutions not only enhances product longevity but also offers a strategic edge in today's competitive electronics market. As investors increasingly prioritize sustainability, the business case for durable manufacturing becomes clearer. Cost-benefit analysis plays a crucial role here, allowing companies to weigh the long-term savings from reduced failure rates against the initial investment. Sustainable circuit boards can lead to lower maintenance costs, decreased electronic waste, and improved brand reputation, making them a wise choice for manufacturers concerned about both the environment and their bottom line.

**Tips:** Consider evaluating the lifecycle of your circuit boards to understand maintenance costs and durability impacts better. Collaborating with suppliers focused on sustainability can also streamline this process and enhance your product's market appeal. Finally, introducing durability as a key performance indicator can help align your manufacturing goals with investor expectations.

Moreover, as emerging technologies like AI continue to reshape the electronics landscape, investing in durable solutions is increasingly seen as a proactive measure against risks associated with rapid technological changes. Adopting durable circuit board strategies today can set the stage for future growth and resilience in an unpredictable market.

Future Trends in Circuit Board Manufacturing for Enhanced Durability

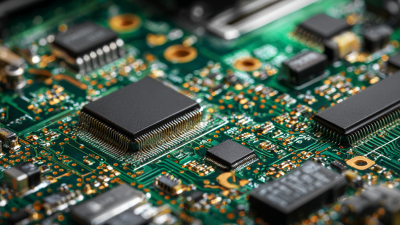

The future of circuit board manufacturing is increasingly focused on enhancing durability, a trend driven by advancements in material science, particularly through the application of nanotechnology. By manipulating materials at the nanoscale, manufacturers can significantly improve the mechanical properties and thermal resistance of circuit boards. Reports indicate that materials enhanced with nanotechnology show a 40% increase in tensile strength and can withstand temperatures exceeding 250°C, making them ideal for demanding applications in automotive and aerospace industries.

Additionally, the integration of bio-microsystems with circuit boards—often referred to as Lab-on-PCB technology—has revolutionized the ability to miniaturize health monitoring devices. A recent survey found that 75% of industry leaders believe that this technology will enable real-time diagnostics, leading to a more efficient healthcare system. As the demand for reliable, durable electronics continues to rise, the intersection of nanotechnology and advanced manufacturing processes will likely define the next generation of circuit boards, ensuring they meet the rigorous standards required in an ever-evolving market.

Benefits of Enhanced Durability in Circuit Board Manufacturing for Electronics

This chart illustrates the percentage improvement level in various aspects of durability for circuit boards, showcasing the importance of enhanced durability in electronic manufacturing.

Related Posts

-

Addressing Common Challenges in Sourcing the Best PCB Circuits for Global Buyers

-

Leading the Way: Unmatched Export Strength of China’s Top PCB Circuit Boards

-

Exploring Unique Features and Applications of the Best Electronic Board Alternatives for Global Buyers

-

Innovative Circuit Board Assembly Techniques Shaping the Future of Electronics

-

The Future of Aluminum PCB: Innovations Driving Sustainable Electronic Design

-

Digital Insights and Tips for Optimizing Your Flexible Printed Circuit Design Process