Exploring Unique Alternatives to Flexible PCB Board Solutions

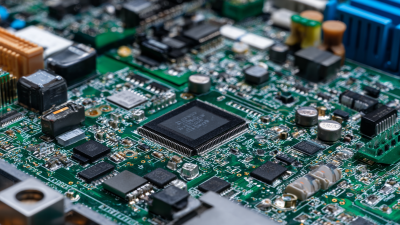

As the demand for compact and lightweight electronic devices continues to rise, flexible PCB boards have emerged as a revolutionary solution in circuit design, enabling manufacturers to meet the growing needs of various industries, including telecommunications, automotive, and medical devices. However, recent industry reports indicate that while flexible PCB boards offer advantages such as improved space utilization and adaptability, they also come with significant challenges, including higher costs and material limitations. According to a market analysis by Research and Markets, the global flexible printed circuit board market is expected to reach $25.71 billion by 2025, underscoring the necessity for alternative solutions that address these problems. As we explore unique alternatives to flexible PCB board solutions, this blog will delve into innovative materials and design approaches that can provide similar benefits with fewer drawbacks, paving the way for the next generation of electronic applications.

Emerging Technologies Revolutionizing Flexible PCB Alternatives

As the demand for wearable technology continues to soar, the shift toward innovative materials and advanced fabrication techniques is ushering in a new era for electronics. Recent advancements in bio-microsystem integration and the development of Lab-on-PCB technology showcase the potential of micro-total analysis systems (µTAS) to integrate multiple functions in a compact form. These innovations support the need for body-conformable electronics that can improve user experience and accessibility across various health monitoring applications.

Moreover, the exploration of alternative materials beyond traditional silicon is revolutionizing electronic device design. Emerging recyclable materials for printed circuit boards (PCBs) not only address sustainability concerns but also enhance the performance and flexibility of future electronics. Reports indicate that the electronic waste from conventional PCB manufacturing is projected to reach a staggering 60 million tons by 2030, highlighting the urgency for eco-friendly solutions. By leveraging environmentally conscious techniques and transformative materials, the industry is poised to reshape how portable electronic devices are built, fostering a greener and more connected future.

Exploring Unique Alternatives to Flexible PCB Board Solutions

| Alternative Technology | Key Features | Advantages | Potential Applications |

|---|---|---|---|

| Hybrid Printed Circuits | Combines organic and inorganic materials | Enhanced durability and flexibility | Wearable electronics, automotive systems |

| 3D Printed Electronics | Directly prints conductive layers | Rapid prototyping and customization | IoT devices, custom sensors |

| Circuit Scribe Technology | Uses conductive ink for drawing circuits | User-friendly and interactive | Education, prototypes for art projects |

| Flexible Hybrid Electronics | Combines rigid and flexible components | Increased functionality in compact formats | Medical devices, smart textiles |

| Organic Electronics | Utilizes organic semiconductors | Eco-friendly and lightweight | Displays, lighting solutions |

Advantages of Non-Flexible Circuit Board Solutions in Modern Applications

In recent years, as the aerospace and defense sectors advance, the demand for reliable and durable electronics has driven innovation beyond traditional flexible PCB board solutions. Non-flexible circuit board solutions have emerged as a strong alternative, offering unique advantages that cater to the evolving needs of modern applications. These rigid boards often provide superior thermal management, enhanced structural integrity, and a more stable platform for high-frequency components, making them ideal for mission-critical systems.

The projected growth of the U.S. and U.K. aerospace and defense PCB market, from $2.23 billion in 2025 to $2.96 billion by 2032, underscores the increasing adoption of these non-flexible solutions. With a compound annual growth rate (CAGR) of 4.1%, industry stakeholders are recognizing the importance of robust circuit designs that can withstand harsh environmental conditions. This shift not only fosters innovation but also enhances reliability, ensuring that systems perform optimally in critical situations, further solidifying the role of non-flexible circuit boards in the future of aerospace and defense technology.

Comparative Analysis: Traditional PCBs vs. Innovative Alternatives

In the rapidly evolving world of electronics, the demand for flexibility in design and function has led to a critical examination of traditional printed circuit boards (PCBs) compared to innovative alternatives. Traditional PCBs, while reliable and widely used, often lack the ability to adapt to the complex geometries required in modern devices. Their rigid construction limits integration into compact spaces or conformable surfaces, which is increasingly necessary in wearables, IoT devices, and automotive applications. As a result, designers are compelled to explore alternatives that offer greater adaptability without compromising performance.

Innovative alternatives like flexible circuit boards (FPCs), rigid-flex circuits, and 3D printed circuits are stepping into the spotlight. FPCs provide enhanced flexibility, allowing for intricate designs that can bend and fit into unconventional spaces. Meanwhile, rigid-flex circuits combine the best of both worlds, offering the reliability of traditional PCBs with the added versatility needed for dynamic applications.

Additionally, advancements in 3D printing technology have paved the way for creating bespoke circuit solutions, enabling rapid prototyping and customization. This comparative analysis highlights a vital shift in the industry, emphasizing the growing preference for innovative alternatives that enhance functionality, streamline production processes, and meet the rising demands of modern electronics.

Sustainability in the Future of PCB Manufacturing Alternatives

As the demand for sustainable solutions continues to rise in the electronics industry, exploring alternatives to traditional flexible PCB manufacturing becomes increasingly essential. A recent report by Research and Markets indicates that the global flexible PCB market is expected to reach USD 25 billion by 2026, highlighting the urgency for more eco-friendly production methods. Sustainable alternatives not only address environmental concerns but can also enhance product lifecycle and reduce waste, offering a path towards greener electronics.

As the demand for sustainable solutions continues to rise in the electronics industry, exploring alternatives to traditional flexible PCB manufacturing becomes increasingly essential. A recent report by Research and Markets indicates that the global flexible PCB market is expected to reach USD 25 billion by 2026, highlighting the urgency for more eco-friendly production methods. Sustainable alternatives not only address environmental concerns but can also enhance product lifecycle and reduce waste, offering a path towards greener electronics.

When considering alternatives to flexible PCBs, companies should focus on materials that prioritize recyclability and lower environmental impact. For instance, biodegradable substrates and organic materials are gaining traction, as they can significantly reduce electronic waste. According to a study by the International Journal of Environmental Science and Technology, using these materials can lower emissions during production by up to 30%.

Tip: Implementing eco-design principles early in the development process can lead to more sustainable products. Assessing supply chain impacts and opting for renewable energy sources during manufacturing can further improve the sustainability credentials of PCB alternatives. Adopting these practices not only meets regulatory demands but also appeals to environmentally conscious consumers.

Case Studies: Successful Implementations of Unique PCB Solutions

In recent years, the demand for flexible printed circuit boards (PCBs) has surged, driven by innovations in consumer electronics, automotive, and medical devices. According to a report by MarketsandMarkets, the flexible PCB market is projected to reach $30 billion by 2026, highlighting its growing significance. However, some manufacturers are exploring unique alternatives to conventional flexible PCB solutions that can offer enhanced performance and reduced costs.

For example, companies are adopting rigid-flex circuits, which combine the best features of rigid PCBs and flexible substrates. A case study involving a leading smartphone manufacturer showcased how rigid-flex designs improved device durability while minimizing space, enabling slimmer profiles without compromising functionality. Another example is the application of printed electronics technology in wearable devices, which allows for lightweight and highly customizable forms that traditional PCBs cannot achieve. This innovative approach resulted in a 25% reduction in production costs for the featured company.

Tips for organizations considering unique PCB solutions include performing a thorough cost-benefit analysis to determine long-term savings, evaluating the reliability and performance benchmarks of alternative materials, and collaborating with design engineers early in the development phase to maximize the benefits of new technologies. Such careful planning can pave the way for successful implementation in diverse applications.

Related Posts

-

Innovative Uses in Aerospace and Challenges in Best Circuit Board Fabrication

-

Solutions for Streamlined Best Circuit Board Assembly: Achieving Excellence in Production

-

The Definitive Handbook to Finding the Best Flexible Printed Circuit Board for Your Needs

-

Unlocking Success: The Advantages of Advanced PCB Fabrication Techniques for Global Buyers

-

Ultimate Guide to Choosing the Best Flexible Printed Circuit Board for Your Project

-

Exploring Unique Features and Applications of the Best Electronic Board Alternatives for Global Buyers