Exploring the Future of PCB Ways: Trends and Innovations in Circuit Board Design for 2024

In 2024, the landscape of PCB ways is anticipated to undergo significant transformations, driven by advancements in technology and increasing demand for more efficient electronic solutions. According to a report from ResearchAndMarkets, the global PCB market is projected to reach USD 100 billion by 2027, growing at a CAGR of 4.9% from 2020. This growth is fueled by innovations such as IoT integration, flexible circuit designs, and the rising complexity of electronic devices. As industries continue to adopt more compact and highly functional PCB ways, design methodologies will need to adapt, incorporating techniques like advanced materials and enhanced fabrication processes. Embracing these trends not only positions companies to meet consumer expectations but also drives sustainability through optimized material usage and energy efficiency. The future of PCB design is not just about performance; it is also about creating smarter, more environmentally friendly solutions for the next generation of electronics.

Emerging Technologies Shaping PCB Design: A Glimpse into 2024

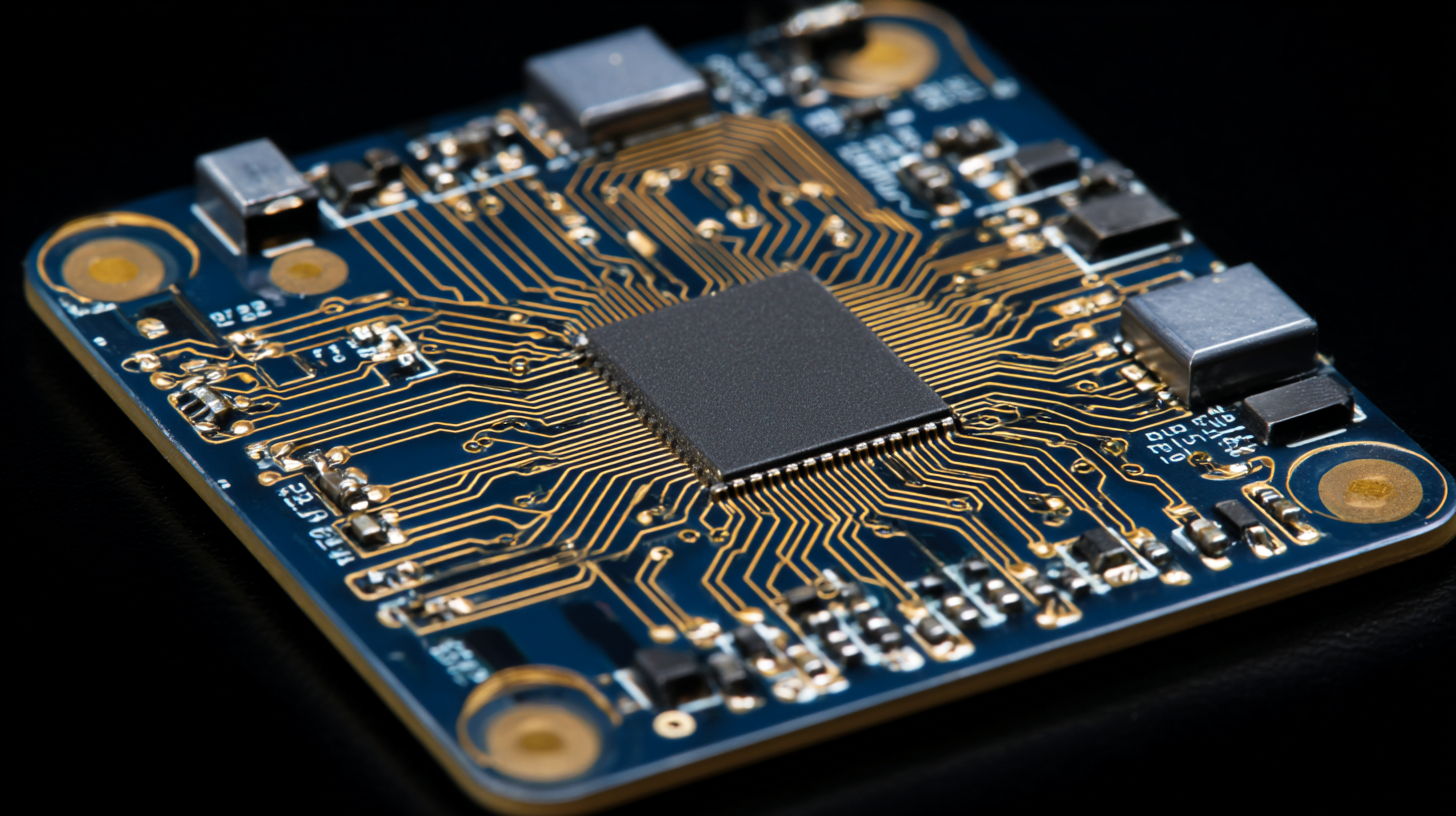

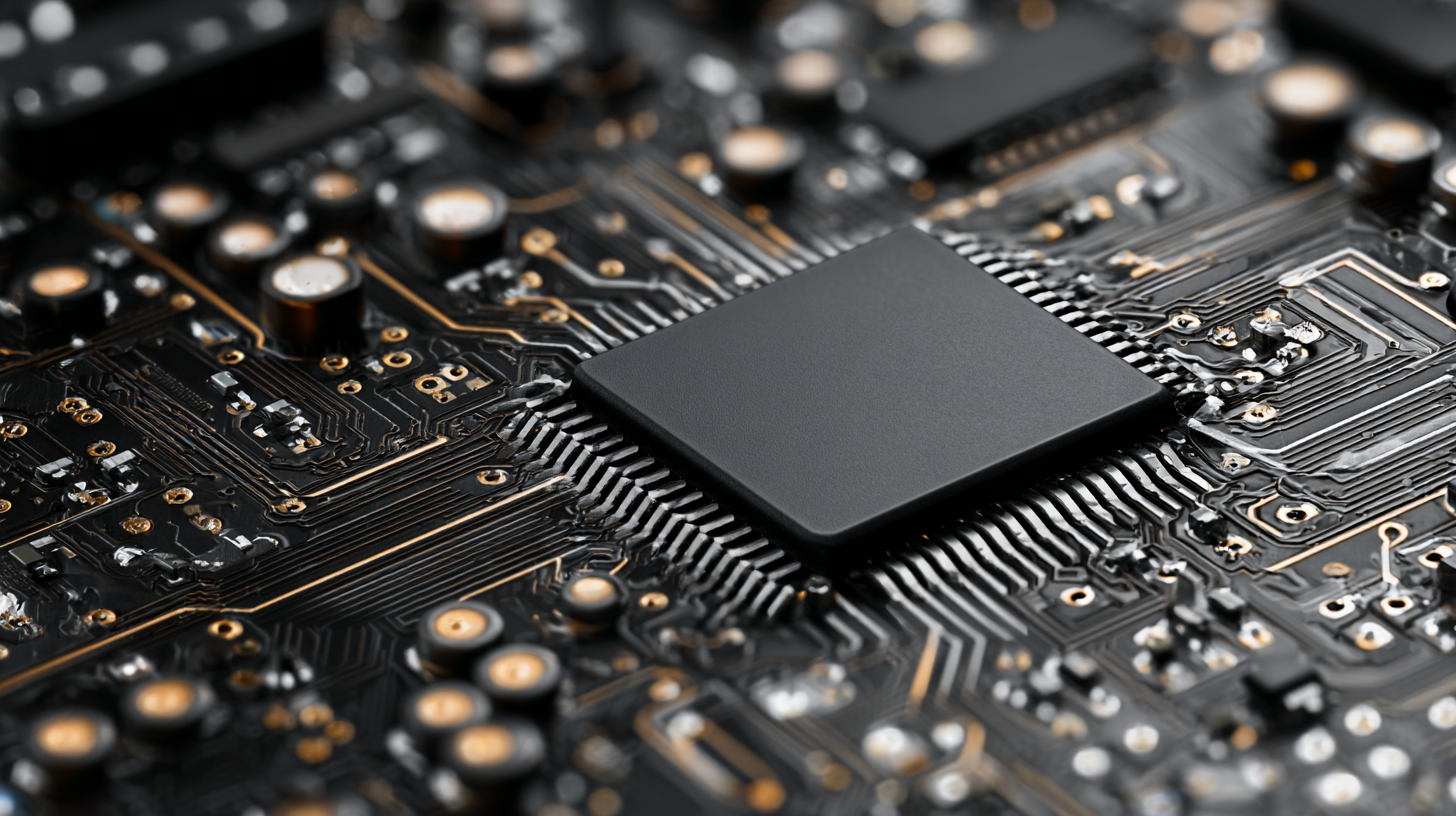

As we look ahead to 2024, several emerging technologies are poised to revolutionize the landscape of printed circuit board (PCB) design. One of the most significant trends is the integration of artificial intelligence (AI) in the design process. AI algorithms can analyze vast amounts of data, predict potential design flaws, and optimize layouts for performance and manufacturability. This not only accelerates the design cycle but also enhances the reliability of PCBs, a crucial factor in an era where electronic devices demand higher functionality in smaller packages.

Additionally, advancements in materials science are reshaping PCB capabilities. Novel materials, such as flexible substrates and high-frequency laminates, are allowing designers to create more compact and efficient circuits. These materials not only enable the production of lighter and more adaptable devices but also enhance thermal management and signal integrity. As industries evolve, the demand for PCBs that can accommodate rapid changes in technology will continue to soar, urging designers to embrace these innovations for more sophisticated, future-ready circuit boards.

Sustainable Materials and Eco-Friendly Practices in Circuit Boards

The shift towards sustainable materials and eco-friendly practices in circuit board design is gaining momentum as we approach 2024. Manufacturers are increasingly prioritizing the use of biodegradable substrates and non-toxic laminates that reduce the environmental footprint of printed circuit boards (PCBs). Innovative materials such as hemp fiber composites and recycled plastics are emerging, allowing for the creation of high-performance boards without compromising ecological integrity. This transition not only addresses the growing consumer demand for sustainability but also aligns with global efforts to reduce electronic waste.

In addition to material innovation, eco-friendly practices in PCB manufacturing are becoming more prevalent. Companies are adopting greener production techniques that minimize energy consumption and reduce harmful emissions. Techniques like water-based soldering and the use of renewable energy sources during manufacturing processes are examples of how the industry is evolving. As designers and engineers incorporate these sustainable practices into their workflows, they contribute to a more responsible electronics sector, fostering a culture of mindfulness towards the environment while still meeting the high standards of performance and reliability expected from modern circuit boards.

Exploring the Future of PCB Ways: Trends and Innovations in Circuit Board Design for 2024 - Sustainable Materials and Eco-Friendly Practices in Circuit Boards

| Material | Type | Sustainability Rating | Applications | Innovative Features |

|---|---|---|---|---|

| Biodegradable Plastics | Polymers | A+ | Consumer Electronics | Compostable and recyclable |

| Recycled Copper | Conductive Material | A | Automotive | Reduced environmental impact |

| Eco-Friendly Laminates | Composite | A+ | Telecommunications | Lower energy consumption |

| Bio-based Epoxy Resins | Resins | A | Industrial Equipment | Improved performance with lower toxicity |

| Metalized Paper | Insulation | B+ | Consumer Goods | Lightweight and cost-effective |

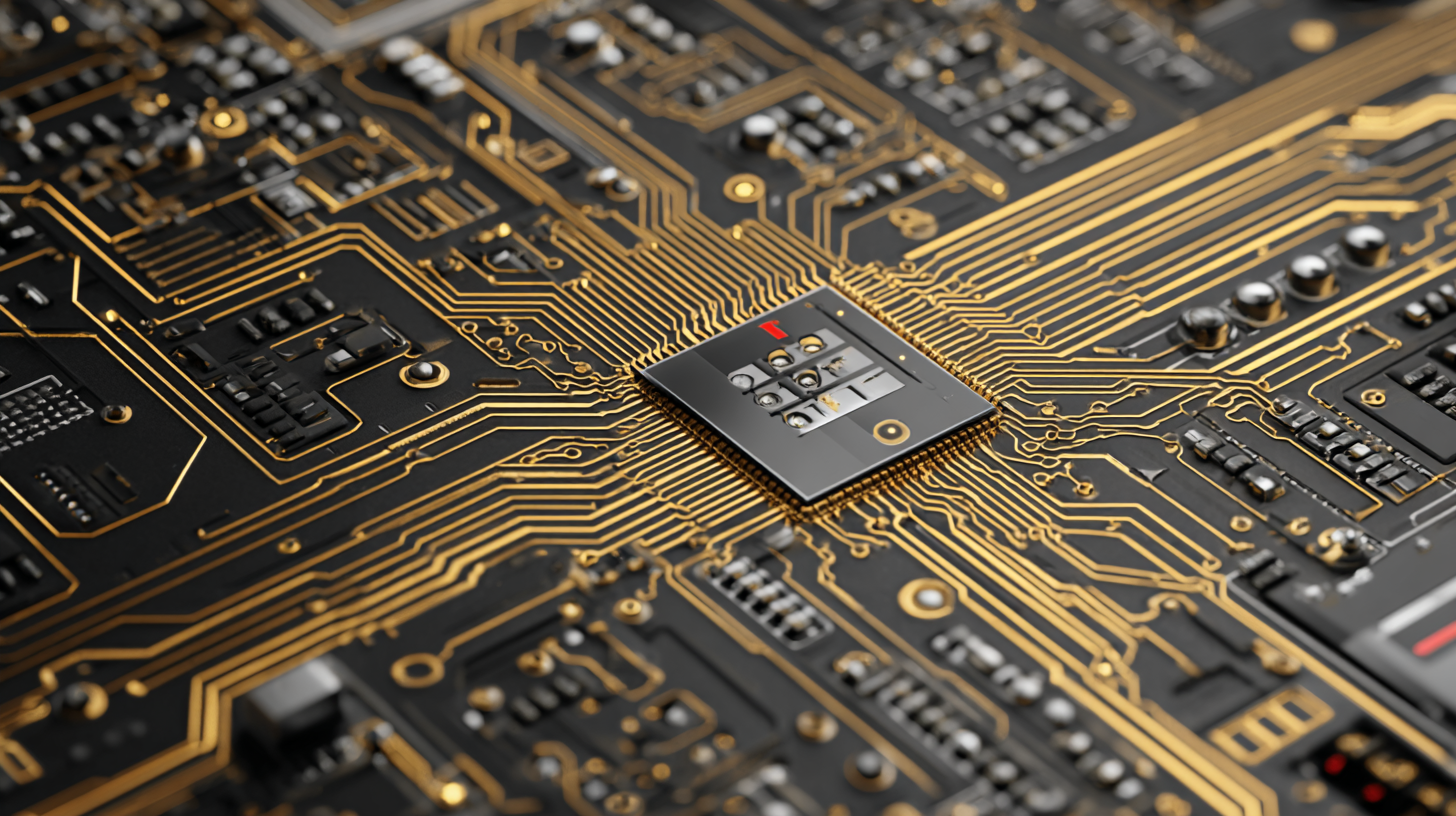

The Role of AI and Machine Learning in PCB Development

As we delve into the evolving landscape of printed circuit board (PCB) design, the integration of artificial intelligence (AI) and machine learning (ML) is poised to revolutionize the industry in 2024. According to a report from MarketsandMarkets, the global AI in the electronics market is expected to grow from $1.1 billion in 2021 to over $8 billion by 2026, demonstrating the rapid adoption of AI technologies across various sectors, including PCB development.

These advancements empower designers to automate time-consuming tasks, optimize layouts, and enhance the performance of circuit boards.

Machine learning algorithms are increasingly being utilized to predict design failures and optimize manufacturing processes. A study by the International Journal of Electronics reports that companies utilizing AI-driven tools in their PCB design processes have noted a reduction in production time by up to 30%. This efficiency gain not only accelerates the time-to-market for new products but also significantly lowers costs associated with prototyping and testing. As we move into the next year, the synergy between AI and PCB design is set to unlock unprecedented capabilities, pushing the boundaries of innovation and operational efficiency in the electronics industry.

Machine learning algorithms are increasingly being utilized to predict design failures and optimize manufacturing processes. A study by the International Journal of Electronics reports that companies utilizing AI-driven tools in their PCB design processes have noted a reduction in production time by up to 30%. This efficiency gain not only accelerates the time-to-market for new products but also significantly lowers costs associated with prototyping and testing. As we move into the next year, the synergy between AI and PCB design is set to unlock unprecedented capabilities, pushing the boundaries of innovation and operational efficiency in the electronics industry.

Trends in Miniaturization and Integration for Future Circuit Boards

As we delve into the future of printed circuit board (PCB) design, miniaturization and integration stand out as defining trends for 2024. The relentless pursuit of smaller, more efficient circuit boards is revolutionizing the technology landscape. Engineers are increasingly employing advanced materials and innovative manufacturing techniques to achieve compact designs without compromising performance. This shift towards smaller form factors enhances the portability and functionality of devices, driving innovation across industries from consumer electronics to medical devices.

Simultaneously, integration plays a crucial role in the evolution of circuit boards. The trend is moving towards combining multiple functions onto a single board, reducing the need for discrete components. This not only saves space but also streamlines the manufacturing process, leading to cost savings and improved reliability. With the rise of IoT devices and the demand for smart technology, integrated solutions will become essential for meeting the growing need for connected, multifunctional devices. As we look to the future, the merging of miniaturization and integration will undoubtedly transform the way we design and utilize PCBs, paving the way for smarter, more efficient technology solutions.

Advancements in 3D Printing and Its Impact on PCB Fabrication

As the landscape of PCB fabrication continues to evolve, 3D printing stands at the forefront of innovation, revolutionizing how circuit boards are designed and produced. Recent advancements in additive manufacturing technologies are enabling the integration of multi-material 3D printing, which significantly enhances the functionality and performance of electronic components. Notably, the global PCB assembly market is anticipated to reach USD 161.6 billion by 2035, with a projected compound annual growth rate (CAGR) of 5.0% from now until then. This growth is driven by the increased adoption of sustainable and flexible materials that align with modern environmental standards.

In Thailand, investments are surging in AI-driven factories aimed at boosting PCB production capabilities, reflecting a broader trend towards smart manufacturing. These innovations not only streamline production but also elevate the potential for customized, on-demand circuit board solutions. As companies integrate AI with 3D printing technology, the design cycle can be significantly shortened, allowing businesses to respond swiftly to market changes and technological advancements. The ongoing exploration of Lab-on-PCB technology further exemplifies the potential uses of 3D printing in healthcare and biosystems, highlighting a future where circuit boards play a vital role in various cutting-edge applications.

Exploring the Future of PCB Ways: Trends and Innovations in Circuit Board Design for 2024

Related Posts

-

Unlocking Success: The Advantages of Advanced PCB Fabrication Techniques for Global Buyers

-

15 Essential Tips for Efficient Printed Circuit Board Assembly

-

Revolutionizing PCB Printing: Insights from the 138th China Import and Export Fair 2025

-

Unveiling PCB and Assembly Innovations at the 138th China Import and Export Fair 2025

-

Innovative Uses in Aerospace and Challenges in Best Circuit Board Fabrication

-

Leading the Way: Unmatched Export Strength of China’s Top PCB Circuit Boards