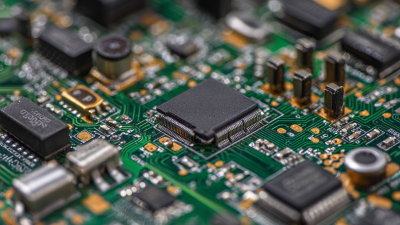

Exploring the Future of Printed Circuit Boards: Trends and Innovations in PCB Technology

The printed circuit board (PCB) industry is at the forefront of technological advancement, driving innovation in various sectors, including consumer electronics, automotive, and telecommunications. According to a recent report by Market Research Future, the global PCB market is expected to reach approximately $90 billion by 2025, growing at a compound annual growth rate (CAGR) of 4.5% from 2019. This growth is attributed to the rising demand for smart devices and the increasing complexity of electronic systems, which necessitate advanced PCB designs. Additionally, trends such as the miniaturization of components and the integration of flexible and high-density interconnect (HDI) boards are shaping the future of PCB technology. As industries seek to enhance performance and reduce manufacturing costs, exploring innovative materials and processes becomes critical, paving the way for the next generation of printed circuit boards.

Emerging Materials in PCB Manufacturing: Enhancing Performance and Sustainability

Recent advancements in PCB manufacturing are leaning heavily towards sustainability and the incorporation of eco-friendly materials. As the chemical industry is projected to grow by 3.5% starting in 2025, many manufacturers are seeking ways to align with emerging eco-conscious standards. This growth has led automotive engineers to explore sustainable interiors that utilize recyclable materials, a trend that is expected to ripple through various sectors including electronics.

Innovations such as bio-based materials are paving the way for new types of printed circuit boards that not only enhance performance but also reduce environmental impact. Research indicates that sustainable PCB manufacturing practices are becoming more prevalent, with a notable shift towards regulatory compliance that emphasizes environmental responsibility. The push for sustainability also aligns with the increasing focus on e-waste recycling, where valuable materials such as rare earth elements can be reclaimed, further supporting the circular economy within the tech industry. These developments underscore a transformative period for PCB technology, where material innovation goes hand in hand with sustainable practices, shaping a greener future for electronics.

Trends and Innovations in PCB Technology

This chart illustrates the projected market growth percentages for various emerging technologies in printed circuit boards (PCBs). As PCB manufacturing evolves, new materials and designs are enhancing both performance and sustainability, with flexible and 3D printed PCBs showing significant growth potential.

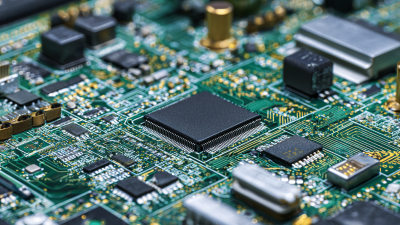

The Rise of Flexible PCBs: Adapting to Wearable and IoT Technologies

The rise of flexible printed circuit boards (PCBs) marks a significant shift in the electronics industry, especially in response to the increasing demand for wearable devices and Internet of Things (IoT) technologies. Unlike traditional rigid circuit boards, flexible PCBs can bend, fold, and conform to various shapes, providing innovative solutions in product design. This adaptability makes them ideal for wearables such as smartwatches and fitness trackers, which require compact, lightweight, and durable circuit solutions that can withstand motion and physical stress.

Moreover, flexible PCBs play a critical role in the expansion of IoT applications. As devices become smaller and more interconnected, the need for efficient, space-saving circuitry has never been more pronounced. Flexible PCBs facilitate this by enabling intricate designs that support multiple functionalities in a small footprint. This trend not only enhances device performance but also opens avenues for new applications in smart homes, healthcare monitoring, and beyond, ultimately driving forward the future of electronics in a rapidly evolving technological landscape.

Advancements in PCB Design Software: Streamlining the Development Process

The landscape of printed circuit board (PCB) technology is rapidly evolving, driven by advancements in design software that significantly enhance the development process.

Modern PCB design tools now incorporate features such as real-time collaboration, artificial intelligence-assisted design suggestions, and automated routing capabilities. These innovations not only streamline the workflow but also reduce the time to market for new electronic products.

Moreover, the integration of simulation and modeling tools allows engineers to test and validate their designs virtually before any physical prototypes are created. This minimizes costly errors and accelerates the iterative design process. Additionally, cloud-based platforms enable teams to work seamlessly across different locations, facilitating a more flexible and productive work environment. The continual evolution of PCB design software is crucial in meeting the increasing demands for smaller, more efficient, and more complex electronic devices in today's tech-driven world.

Innovative Thermal Management Solutions in PCB Technology

The future of printed circuit boards (PCBs) is poised for exciting advancements, particularly in the realm of thermal management solutions. As electronic devices become increasingly compact and powerful, effective heat dissipation is critical to maintain performance and reliability. Innovative approaches, such as advanced thermal interface materials and embedded passive cooling systems, are emerging to tackle the challenges posed by higher operational temperatures. These technologies not only enhance thermal conductivity but also contribute to the overall longevity of the PCB.

**Tips:** When selecting thermal management materials, consider their thermal conductivity and adhesive properties. Ensure compatibility with the specific PCB materials to avoid any adverse reactions. Additionally, keep an eye on the latest developments in nano-cooling technology, which promises improved performance in managing heat in densely packed circuits.

Moreover, the integration of active cooling solutions, like micro fans and electrostatic devices, is gaining traction. These innovations allow for dynamic responses to thermal loads, adjusting cooling efforts based on real-time temperature data. This adaptive performance can significantly enhance the reliability of high-performance electronics, paving the way for superior device efficiency.

**Tips:** Regular thermal performance testing can help identify potential issues early. Invest in temperature monitoring solutions to gather data on PCB performance, enabling proactive maintenance strategies that ensure optimal functionality in demanding applications.

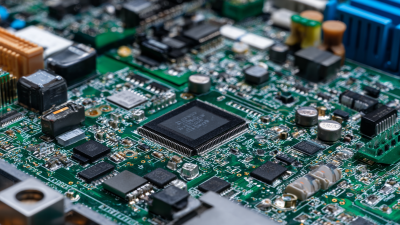

Automating PCB Production: The Impact of AI and Robotics on Efficiency

The advent of artificial intelligence (AI) and robotics is revolutionizing the production of printed circuit boards (PCBs), enhancing efficiency and precision in manufacturing processes. Automated systems can now perform tasks previously reliant on human labor, such as soldering, inspection, and assembly. This shift not only speeds up production cycles but also minimizes human error, leading to higher quality outputs. AI-driven algorithms analyze data in real-time to adapt processes and increase yield, allowing for more consistent and reliable products.

Moreover, the integration of robotics in PCB production facilitates a more streamlined workflow. Collaborative robots, or cobots, are designed to work alongside human operators, taking over repetitive or physically demanding tasks. This synergy allows workers to focus on more complex issues that require critical thinking, thereby fostering innovation within manufacturing environments. As companies adopt these technologies, they are positioned to respond swiftly to market demands, making the PCB sector both agile and competitive in an increasingly fast-paced industry.

Related Posts

-

Benefits of Enhanced Durability in Circuit Board Manufacturing for Electronics

-

How to Design and Manufacture a High-Quality Printed Circuit Board from Scratch

-

Addressing Common Challenges in Sourcing the Best PCB Circuits for Global Buyers

-

Leading the Way: Unmatched Export Strength of China’s Top PCB Circuit Boards

-

Exploring Unique Features and Applications of the Best Electronic Board Alternatives for Global Buyers

-

10 Smart Tips for Mastering PCB Circuit Design in the Digital Era