Innovative Applications of Flexible PCB Boards in Modern Electronics

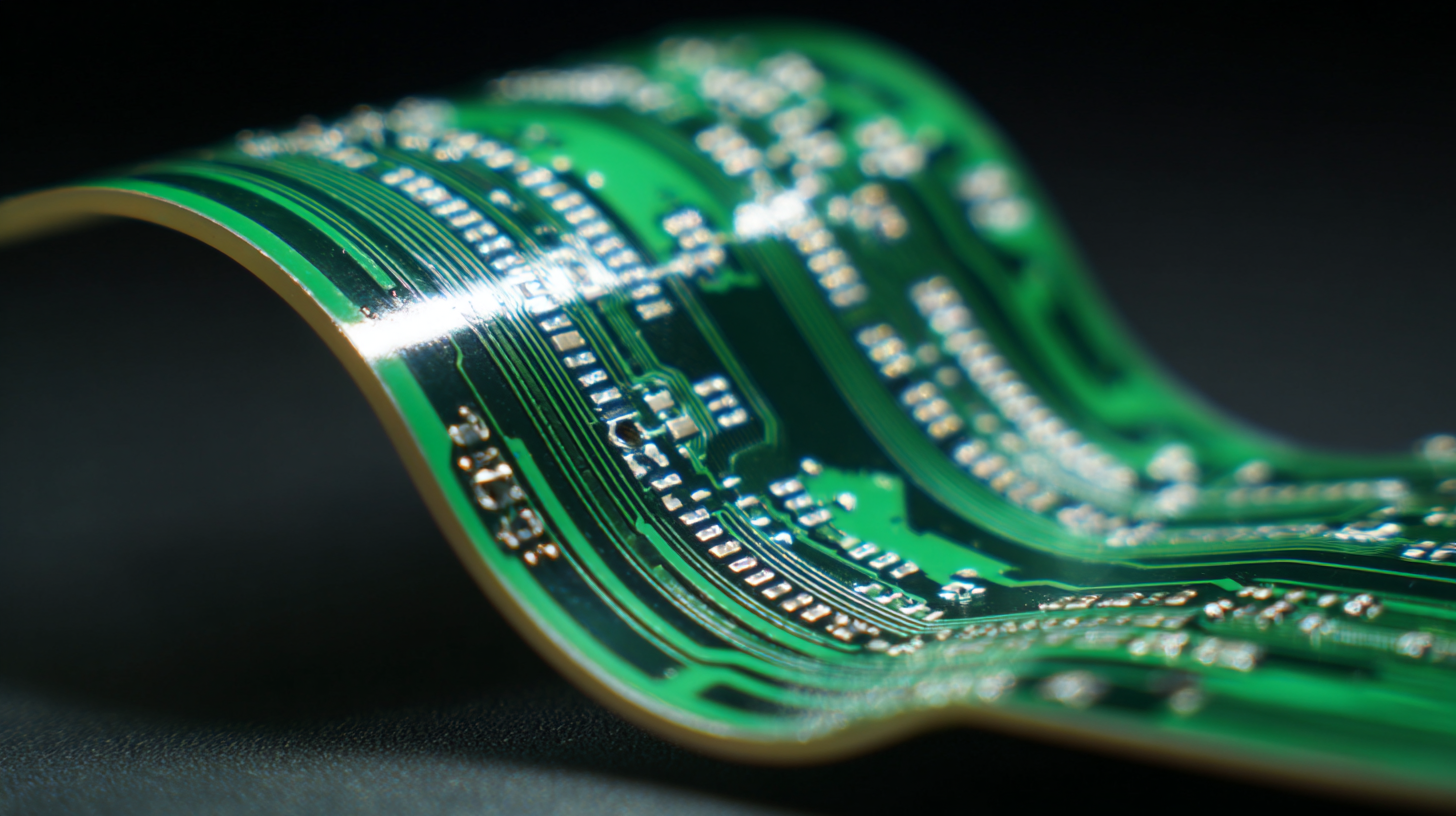

In the ever-evolving landscape of modern electronics, the advent of flexible PCB boards has revolutionized the way devices are designed and manufactured. These innovative circuit boards offer unparalleled versatility, enabling engineers to create compact, lightweight, and adaptable electronic solutions that cater to a wide range of applications, from wearable technology to advanced consumer electronics.

With their unique ability to bend and conform to various shapes, flexible PCB boards allow designers to push the boundaries of traditional circuitry, integrating electronics into unconventional spaces without compromising performance. This introduction aims to explore the myriad applications and benefits of flexible PCB boards, highlighting practical tips for leveraging their potential in the design of next-generation electronic devices. As we delve into this topic, we will uncover how flexible PCBs are not just a trend, but a pivotal solution in crafting smarter, more efficient technology in today's digital age.

Understanding Flexible PCB Technology: A Comprehensive Overview

Flexible printed circuit boards (PCBs) have revolutionized modern electronics, providing unparalleled adaptability in design and functionality. Unlike traditional wire-based systems, advanced catheter designs utilize flexible PCBs to enhance performance and patient comfort, leading to significant innovations in medical technology. This transition has enabled the creation of devices that are not only efficient but also adaptable to the complex human anatomy, improving the effectiveness of various medical procedures.

In addition to medical applications, the scope of flexible PCB technology extends into areas like robotics and wearable devices. Recent reviews highlight the development of flexible robotic gripping systems designed for enhanced versatility in various industrial sectors. Furthermore, emerging technologies such as stretchable MRI coils demonstrate the potential of flexible electronics to conform to the body, significantly improving diagnostic capabilities while maintaining patient comfort. As this technology continues to evolve, it is poised to play a critical role in shaping the future of electronics across multiple industries.

Key Advantages of Using Flexible PCBs in Modern Electronics

Flexible PCB boards, or printed circuit boards, have revolutionized the realm of modern electronics by offering a multitude of advantages that traditional rigid boards cannot match. One of the key benefits is their remarkable space-saving capability. These PCBs can be shaped and bent to fit into compact and unconventional spaces, making them ideal for applications in smartphones, wearables, and other portable devices. By utilizing flexible PCBs, manufacturers can design sleeker products without compromising performance or functionality.

Tips: When designing with flexible PCBs, consider the bending radius and the materials used in the substrates. Ensuring that the design accounts for the potential stresses during operation can significantly enhance the reliability of the final product.

Another advantage of flexible PCBs is their lightweight nature. This characteristic not only reduces the overall weight of electronic devices but also contributes to energy efficiency. Lighter components can lead to less energy consumption, which is particularly beneficial in battery-powered devices. Additionally, flexible PCBs exhibit superior thermal management properties, allowing better heat dissipation in densely packed electronic assemblies.

Tips: Always evaluate the thermal properties of both the PCB material and the circuit design to optimize performance and longevity. Proper thermal management strategies will ensure your device operates smoothly even under high-power conditions.

Innovative Applications of Flexible PCB Boards in Modern Electronics

| Application Area | Key Advantages | Material Used | Typical Thickness | Cost Efficiency |

|---|---|---|---|---|

| Wearable Technology | Lightweight, conformable design | Polyimide | 0.1 mm - 0.5 mm | High efficiency, reduced waste |

| Consumer Electronics | Enhanced durability, flexible design | FR-4, Polyimide | 0.2 mm - 1.0 mm | Lower assembly costs |

| Medical Devices | Compact design, high reliability | Liquid crystal polymer (LCP) | 0.1 mm - 0.4 mm | Reduced downtime; improved performance |

| Automotive Electronics | Space-saving, weight reduction | PET, Polyimide | 0.2 mm - 0.8 mm | Improved fuel efficiency |

Innovative Applications of Flexible PCBs Across Various Industries

Flexible PCB boards have revolutionized the electronics industry by enabling innovative designs across various sectors. In consumer electronics, for example, flexible PCBs allow manufacturers to create lightweight and compact devices, such as smartphones and wearable tech, that conform to modern lifestyles. These boards accommodate complex circuitry in limited spaces, paving the way for sleek designs that do not compromise functionality.

In the automotive industry, flexible PCBs play a crucial role in advancing vehicle technology. Their ability to withstand extreme temperatures and vibrations makes them ideal for applications in infotainment systems, sensor technology, and electric vehicle components. The integration of flexible PCBs contributes to enhancing vehicle performance and safety while enabling more streamlined designs.

Tip: When considering the use of flexible PCBs, it’s essential to choose materials that are suitable for your application’s environmental conditions. Assess factors such as temperature range, humidity, and mechanical stress to ensure long-term reliability.

Moreover, in the medical field, flexible PCBs have opened doors for innovative health monitoring devices and implantable technologies. These boards provide the needed flexibility for wearables that track vital signs without causing discomfort to the user. The ease of integrating advanced sensors into flexible circuits fosters advancements in patient care and personalized medicine.

Tip: Prior to designing your flexible PCB, conduct thorough research on compatibility with other electronic components to avoid potential malfunctions during operation.

Design Considerations for Enhancing Flexible PCB Performance

The rapid evolution of electronic devices necessitates innovative approaches in design, particularly in the realm of flexible printed circuit boards (PCBs). To enhance the performance of flexible PCBs, designers must consider several critical factors such as materials, layer stacking, and mechanical stability. The choice of substrate materials, like polyimide or polyethylene terephthalate (PET), plays a significant role in determining the flexibility and thermal resistance of the PCB. These materials should be selected based on the specific application requirements, ensuring they can withstand both environmental stresses and operational temperatures.

Another important design consideration is the layer stacking architecture. Multi-layer designs can significantly increase circuit density, but they also require meticulous planning to optimize signal integrity and minimize electromagnetic interference (EMI). Implementing controlled impedance design strategies can enhance performance by preventing signal degradation. Additionally, engineers should prioritize mechanical stability by incorporating reinforcements at critical points, ensuring durability without sacrificing flexibility. Overall, careful attention to these design elements can significantly improve the functionality and reliability of flexible PCBs in modern electronic applications.

Performance Metrics of Flexible PCB Boards

Future Trends and Developments in Flexible PCB Technology

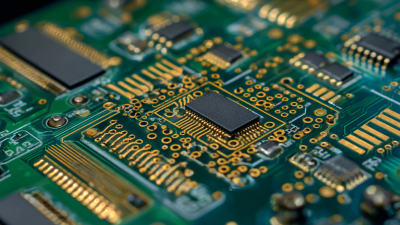

The flexible printed circuit board (FPCB) market is poised for significant growth, driven by advancements in technology and the increasing demand for miniaturized electronic devices. According to a report by Research and Markets, the flexible PCB market was valued at approximately $25 billion in 2022 and is expected to surge to $41 billion by 2028, reflecting a CAGR of around 8.5%. This growth trajectory indicates not only a rising adoption of flexible PCBs in consumer electronics but also their critical role in applications such as wearable technology, medical devices, and automotive systems.

Future trends in flexible PCB technology point towards enhanced material development and manufacturing techniques that will facilitate even greater flexibility and durability. Emerging materials, including high-frequency and low-loss dielectric substrates, are being researched to improve performance in high-speed applications. Additionally, the incorporation of sustainable manufacturing practices is gaining attention; the global shift towards environmentally-friendly electronics is further encouraging innovations in FPCB production. As industries continue to evolve, the integration of flexible PCBs in next-generation electronic systems will likely redefine design paradigms, offering unprecedented possibilities for compact and efficient device architecture.

Related Posts

-

Exploring Unique Alternatives to Flexible PCB Board Solutions

-

Understanding the Benefits and Applications of Flexible PCB Boards in Modern Electronics

-

Digital Insights and Tips for Optimizing Your Flexible Printed Circuit Design Process

-

12 Innovative Advantages of Flexible Printed Circuits You Need to Know

-

Leading the World with Premium Heavy Copper PCBs from China's Best Manufacturers

-

Innovative Circuit Board Assembly Techniques Shaping the Future of Electronics