How to Optimize Printed Circuit Board Assembly for Better Performance?

In the rapidly evolving world of technology, optimizing printed circuit board assembly (PCBA) is crucial for superior performance. According to Dr. Emily Chen, a leading expert in electronic manufacturing, "Efficient PCBA not only enhances product reliability but also reduces overall costs." This insight underscores the importance of fine-tuning every stage of the assembly process.

Many manufacturers overlook simple aspects that can make a significant difference. For instance, the choice of materials and soldering techniques can dramatically affect durability. Often, teams may accept a standard approach without considering the unique requirements of their specific application. Such complacency can lead to higher failure rates in the field.

Furthermore, integrating testing and verification early in the design phase is often neglected. This oversight may seem minor, yet it can save substantial time and resources in the long run. By adopting a proactive mindset, businesses can push the boundaries of what effective printed circuit board assembly looks like, leading to innovations and enhanced product offerings.

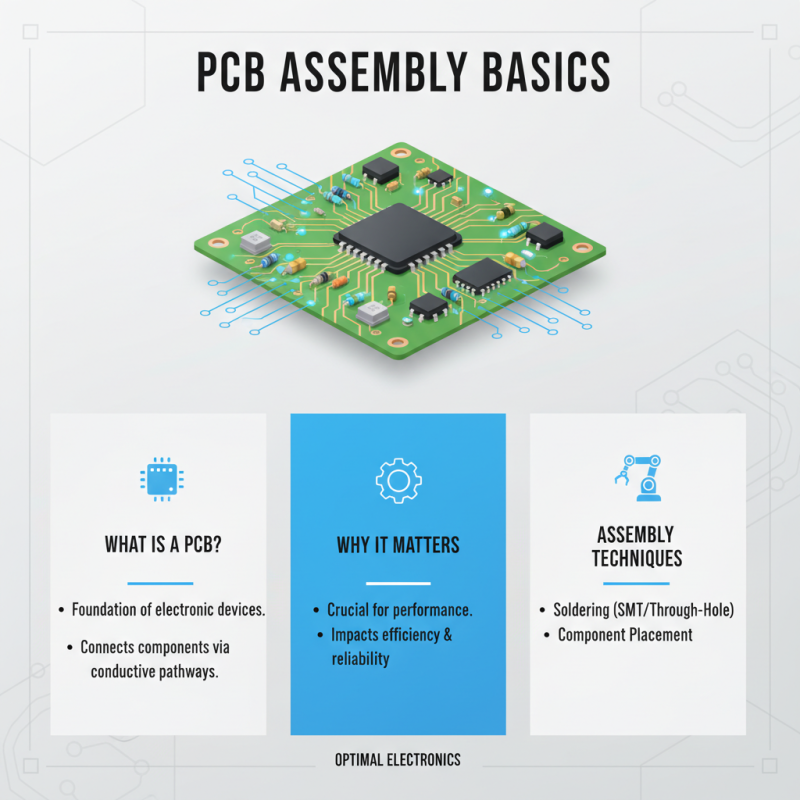

Understanding the Basics of Printed Circuit Board Assembly Techniques

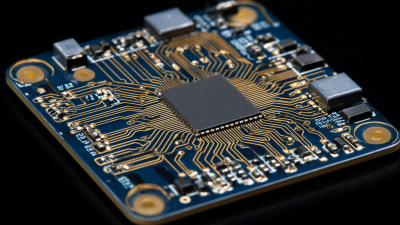

Understanding the basics of printed circuit board (PCB) assembly is crucial for achieving optimal performance. PCBs are fundamental components in electronic devices. They connect various components through conductive pathways. The assembly process involves several techniques that can significantly impact efficiency and reliability.

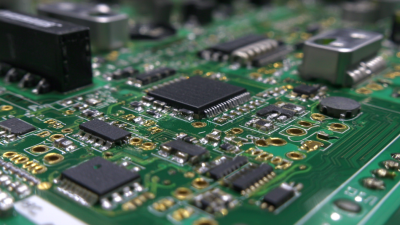

Surface mount technology (SMT) is a popular method for PCB assembly. It allows components to be mounted directly onto the surface of the board. This technique leads to smaller and lighter assemblies. However, it requires precision. Any misalignment can affect performance and durability.

Through-hole technology is another method. This involves inserting component leads through holes in the PCB. While it's more robust, it can lead to larger boards. Each technique has its pros and cons. Understanding these nuances is vital. Many manufacturers overlook details, leading to potential issues down the line. Fine-tuning these processes can lead to better performance overall. Attention to detail is essential for success.

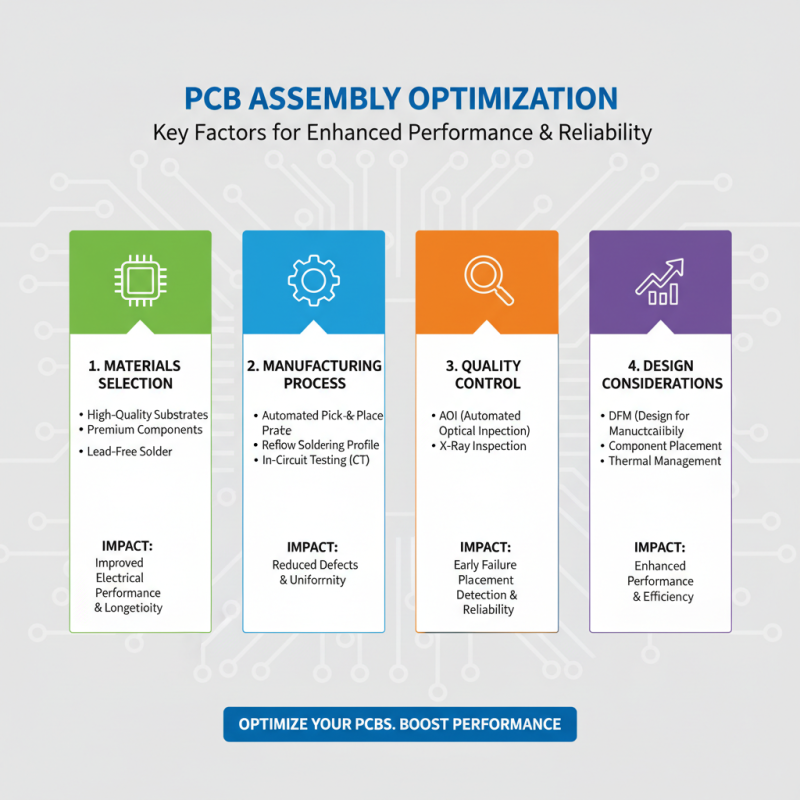

Key Factors Affecting Performance in PCB Assembly

Optimizing printed circuit board (PCB) assembly is crucial for enhanced performance. Several key factors affect the efficiency and reliability of your PCB assembly process. One primary aspect is the choice of materials. High-quality materials can significantly improve electrical performance. Conversely, using subpar materials can lead to failures.

Tips: Always evaluate your suppliers. Ensure they can provide materials that meet your specifications. A reliable supply chain is essential for consistent quality.

Another critical factor is the design layout. A well-thought-out layout can enhance signal integrity and reduce electromagnetic interference. Poorly designed layouts may cause connectivity issues. Reflect on previous designs. Were there areas that led to delays or defects? Small tweaks can yield substantial benefits.

Tips: Regularly review and update design standards. Keep track of common design pitfalls to avoid. Collaborate with a skilled design team to spot potential issues early.

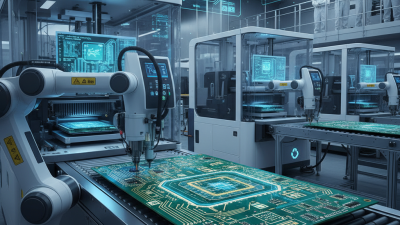

Lastly, assembly techniques play a vital role. Automated processes can reduce errors, but they also require regular maintenance. Human oversight is equally important. Resist the urge to rely solely on automation. Are your operators adequately trained? Investing in training can lead to better outcomes.

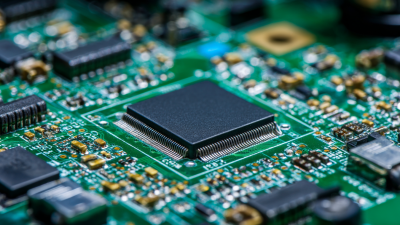

Best Practices for Component Placement in PCB Design

Placement of components on a printed circuit board (PCB) significantly impacts the overall performance. A well-optimized layout can reduce electromagnetic interference and improve thermal management. According to a recent industry report, improper component placement accounts for approximately 30% of PCB failures.

Optimal positioning of components starts with a clear hierarchy. Power components should be placed centrally. Keep signal paths short. This layout minimizes inductance and reduces noise. When components are crammed together, performance suffers. For instance, placing high-frequency components too close to analog parts can cause crosstalk.

Spacing matters too. Maintain adequate distances between sensitive components to avoid interference. A study showed that increasing spacing can improve signal integrity by as much as 40%. However, many designers overlook this. They prioritize a compact design over functionality. Reflecting on this, there’s a need to balance efficiency with performance. Making rational placement choices can lead to better outcomes in assembly quality.

How to Optimize Printed Circuit Board Assembly for Better Performance? - Best Practices for Component Placement in PCB Design

| Component Type | Placement Strategy | Impact on Performance | Recommended Distance | Notes |

|---|---|---|---|---|

| Resistor | Place near ICs | Minimizes signal delay | < 1 cm | Avoid placement near RF components |

| Capacitor | Place close to power pins | Improves power stability | < 0.5 cm | Use decoupling capacitors |

| Inductor | Isolate from sensitive components | Reduces EMI | > 2 cm | Consider current ratings |

| Microcontroller | Central placement | Optimizes overall layout | N/A | Ensure adequate grounding |

| Connector | Edge of the PCB | Facilitates easier access | N/A | Use lockable connectors for durability |

Implementing Quality Control Measures in PCB Assembly

Quality control measures are essential in PCB assembly. They help ensure that each component functions correctly. Regular inspections at various stages of the assembly process can identify defects early. This could mean checking solder joints and verifying component placement. The earlier issues are found, the less costly they are to fix.

Another effective approach is implementing automated testing. Automated testing can detect faults that manual inspections might miss. However, there are challenges. Calibration of testing equipment is crucial. If the equipment is off, it leads to false readings. All tests should be documented for review. This allows teams to identify patterns in defects and address root causes.

Fine-tuning quality control demands attention and effort. It's easy to overlook minor issues during busy periods. Neglecting these can lead to larger problems down the line. Continuous training for assembly line workers is vital. A well-informed team is more likely to recognize and report anomalies. Prioritizing these measures can significantly enhance PCB assembly performance over time.

Integrating Advanced Technologies for Enhanced PCB Performance

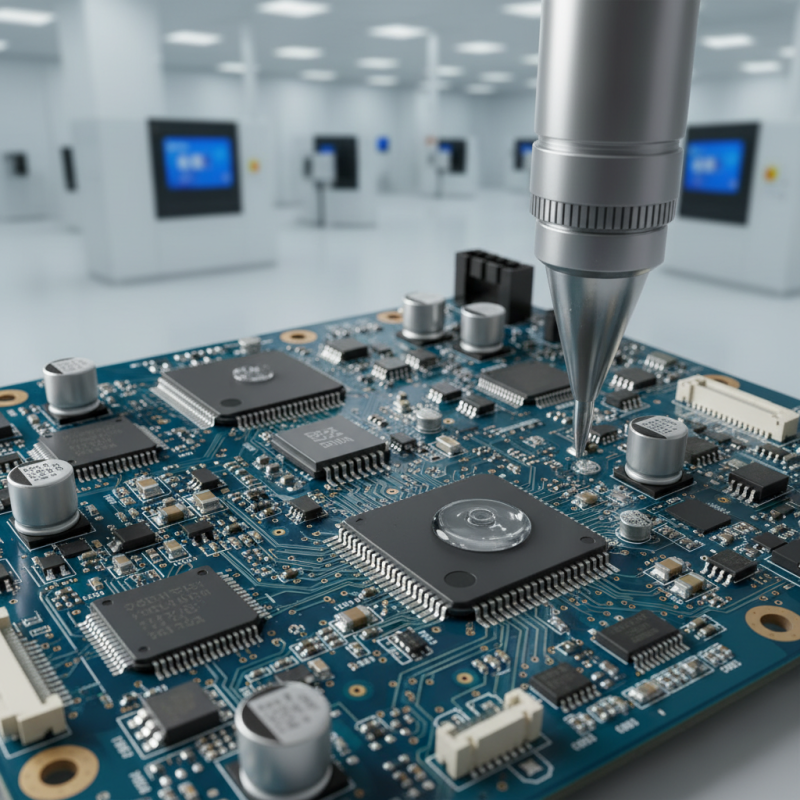

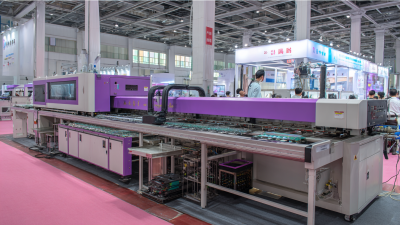

Integrating advanced technologies into printed circuit board (PCB) assembly can significantly enhance performance. The use of automation tools, for instance, can streamline production. Robots can place components with precision, reducing errors. This not only saves time but can improve the overall quality of the assembly.

Tips: Consider investing in software that supports real-time monitoring. Tracking the assembly process can help identify bottlenecks. Make adjustments promptly to avoid delays.

Another area to explore is the application of artificial intelligence (AI). AI can predict potential failures before they happen. This proactive approach reduces waste and increases reliability. However, implementing AI requires skilled personnel, which may spark resistance. Teams might need training to fully utilize these tools.

Tips: Start small with pilot projects. Test AI integration in specific areas first. Gather data and feedback to refine processes over time. This allows for gradual adjustment and avoids overwhelming your team. Embrace the imperfections in this learning process.

Related Posts

-

How to Optimize Printed Circuit Board Assembly for Maximum Efficiency and Quality

-

15 Essential Tips for Efficient Printed Circuit Board Assembly

-

2025 Top PCB Printing Trends: What You Need to Know for Success

-

Exploring the Future of PCB Ways: Trends and Innovations in Circuit Board Design for 2024

-

Unveiling PCB and Assembly Innovations at the 138th China Import and Export Fair 2025

-

Revolutionizing PCB Printing: Insights from the 138th China Import and Export Fair 2025