Unveiling PCB and Assembly Innovations at the 138th China Import and Export Fair 2025

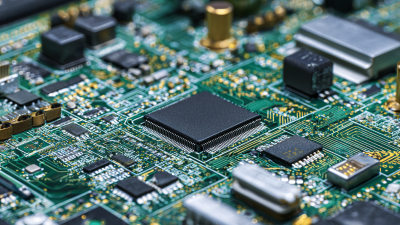

The 138th China Import and Export Fair in 2025 serves as an unprecedented platform for showcasing cutting-edge innovations in the realm of PCB and assembly technologies. As industries increasingly pivot toward sophisticated electronic solutions, the fair highlights the transformative impact of these advancements on various sectors, from consumer electronics to automotive applications. Exhibitors are set to unveil pioneering designs and manufacturing techniques that not only enhance performance but also improve sustainability. This event promises to connect manufacturers, suppliers, and industry stakeholders eager to explore the latest trends and developments in PCB and assembly, creating opportunities for collaboration and growth within the global market. The unveiling of these innovations at such a prestigious gathering underscores the significance of this technology in driving the future of electronics and elevating China's role in the global supply chain.

The 138th China Import and Export Fair in 2025 serves as an unprecedented platform for showcasing cutting-edge innovations in the realm of PCB and assembly technologies. As industries increasingly pivot toward sophisticated electronic solutions, the fair highlights the transformative impact of these advancements on various sectors, from consumer electronics to automotive applications. Exhibitors are set to unveil pioneering designs and manufacturing techniques that not only enhance performance but also improve sustainability. This event promises to connect manufacturers, suppliers, and industry stakeholders eager to explore the latest trends and developments in PCB and assembly, creating opportunities for collaboration and growth within the global market. The unveiling of these innovations at such a prestigious gathering underscores the significance of this technology in driving the future of electronics and elevating China's role in the global supply chain.

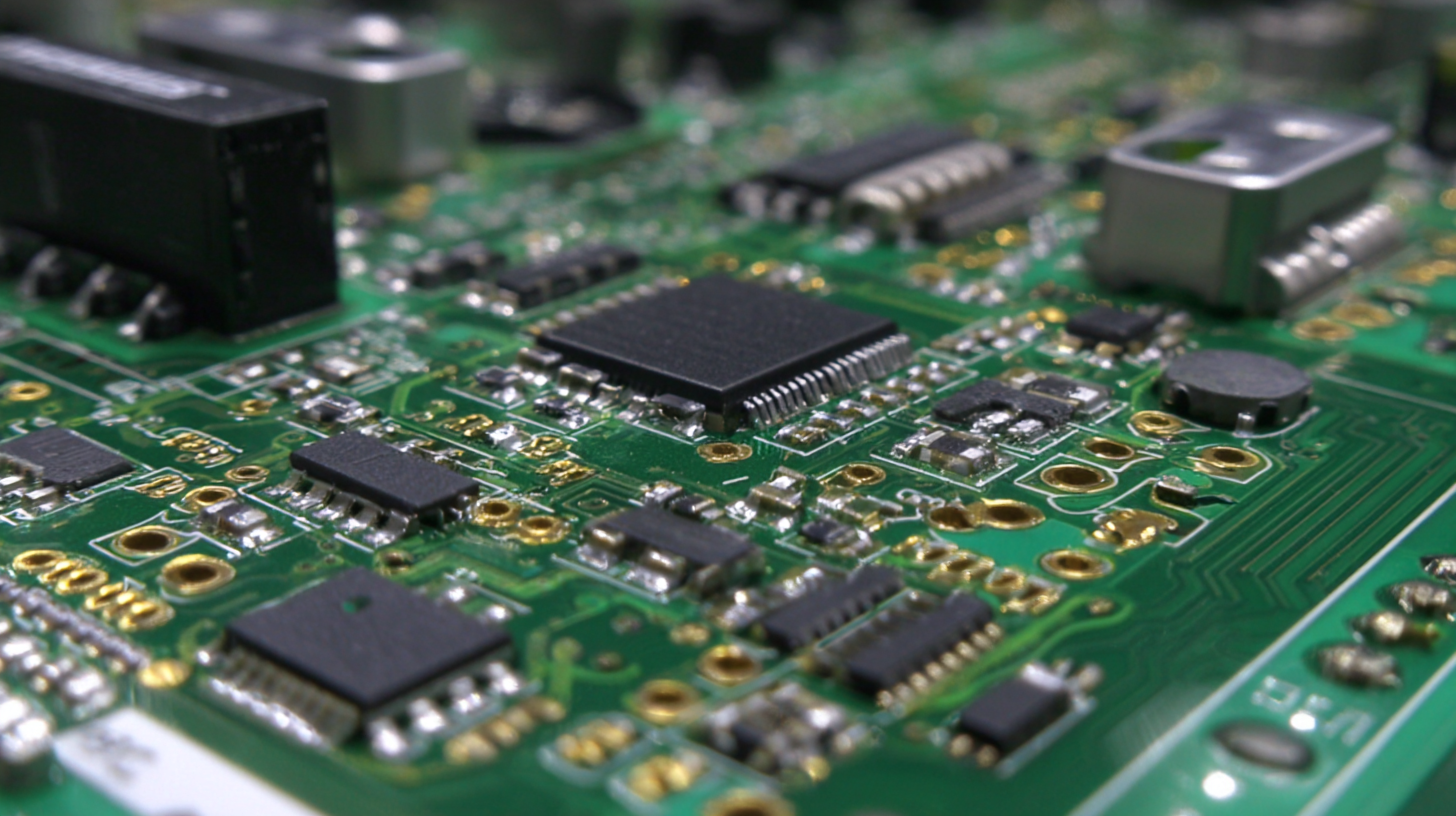

Innovative Trends in PCB Technology Showcased at the Fair

The 138th China Import and Export Fair in 2025 serves as a prime platform for showcasing groundbreaking innovations in PCB technology. As the electronics industry evolves, the demand for advanced printed circuit boards (PCBs) continues to surge. Reports forecast that the global PCB market will reach $95 billion by 2026, driven by innovations in smart devices, automotive technology, and IoT applications. The fair highlights significant trends such as flexible and high-density interconnect (HDI) PCBs, which not only improve performance but also reduce space in compact electronic designs.

One of the exciting trends presented at the fair is the rise of environmentally friendly PCB manufacturing processes. With an increasing focus on sustainability, companies are adopting lead-free soldering techniques and eco-friendly materials, aligning with global regulations and consumer expectations. According to a recent industry analysis, green PCBs are expected to constitute over 30% of the market share by 2025.

Tips: When exploring new PCB technologies, consider evaluating suppliers’ commitment to sustainability. Additionally, stay updated on emerging trends in HDI and flexible PCBs to remain competitive in the rapidly changing electronics landscape. Engaging with industry experts during the fair can provide invaluable insights into the future direction of PCB innovations.

The Rise of Eco-Friendly Materials in PCB Manufacturing

The 138th China Import and Export Fair 2025 will showcase significant advancements in PCB (Printed Circuit Board) technology, particularly the increasing adoption of eco-friendly materials in manufacturing. As global environmental concerns rise, manufacturers are transitioning from traditional materials to sustainable alternatives that minimize environmental impact. This focus not only supports regulatory compliance but also satisfies the growing demand from consumers for greener products.

Innovations in PCB manufacturing are now integrating materials such as bioplastics and recycled components, which offer the same reliability and performance as conventional materials while reducing carbon footprints. Additionally, the fair will highlight how these eco-friendly materials can enhance the lifecycle of PCBs, improving their end-of-life recyclability. Companies attending the event will have the opportunity to explore new partnerships and technologies that contribute to a more sustainable future for the electronics industry. The emphasis on eco-friendly solutions signifies a pivotal shift towards responsible manufacturing practices in the PCB sector.

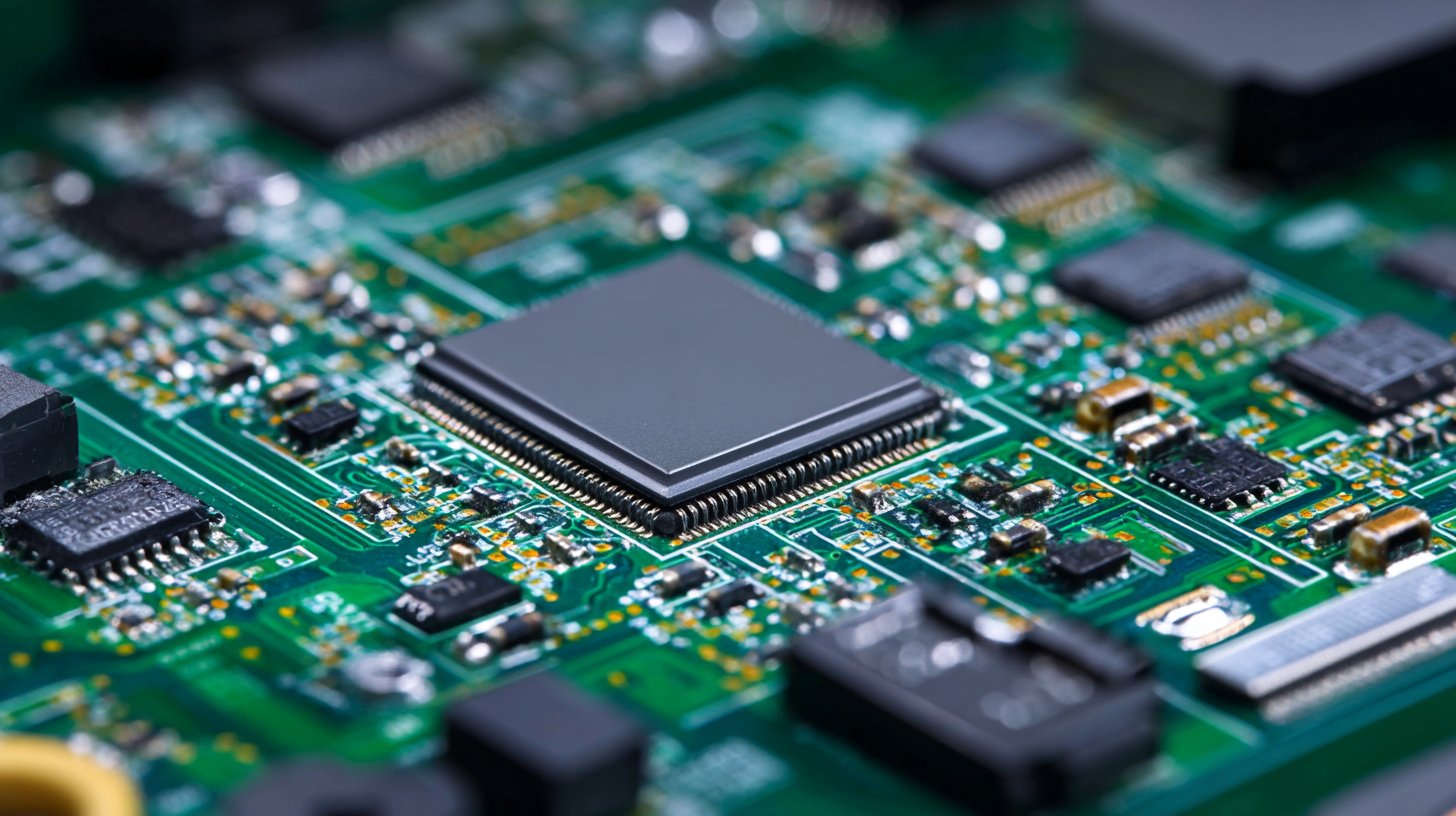

Advanced Assembly Techniques Transforming PCB Production

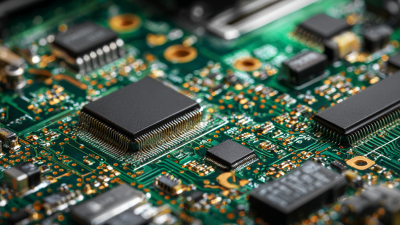

At the 138th China Import and Export Fair 2025, the spotlight will undoubtedly shine on advanced assembly techniques that are revolutionizing PCB production. In recent years, the global printed circuit board (PCB) market has witnessed significant growth, projected to reach approximately $75.2 billion by 2025, according to a report from Research and Markets. This growth is fueled by increasing demand for electronic products and the incorporation of sophisticated technologies in manufacturing processes.

Among the pioneering techniques showcased at the fair, surface mount technology (SMT) is leading the charge in enhancing production efficiency and precision. Studies indicate that SMT can improve assembly speed by up to 70% compared to traditional methods, while significantly reducing errors and material waste. Furthermore, the integration of automation and AI-driven solutions in PCB assembly not only streamlines operations but also optimizes quality control, ensuring that the final products meet the rigorous standards demanded by industries like automotive and telecommunications. As manufacturers adopt these innovative assembly methods, the future of PCB production appears promising, paving the way for more complex and compact electronic designs.

Networking Opportunities for Industry Leaders at the Fair

The 138th China Import and Export Fair 2025 presents a unique platform for industry leaders to forge invaluable connections and expand their professional networks. As the global market continues to evolve, the importance of collaboration within the PCB and assembly sectors becomes increasingly evident. This fair offers a golden opportunity for leaders to meet, share insights, and explore potential partnerships that could drive innovation and enhance competitiveness in the industry.

Networking at the fair will be further enriched by the presence of notable experts and cutting-edge exhibitors showcasing the latest technologies and trends in PCB and assembly. Attendees will have the chance to engage in meaningful discussions, attend seminars, and participate in workshops tailored to current industry challenges and advancements. Such interactions not only foster knowledge exchange but also inspire creative solutions that can benefit all participants in the long run, ultimately pushing the boundaries of what’s possible in manufacturing and assembly processes.

PCB and Assembly Innovations at the 138th China Import and Export Fair 2025

This chart illustrates the percentage growth of various PCB and assembly innovations showcased at the fair, highlighting the trends in the industry for 2025.

Future Prospects of PCB and Assembly Innovations Post-2025

As the global electronics market continues to evolve, the future of Printed Circuit Board (PCB) and assembly innovations post-2025 appears promising. According to a recent report by MarketsandMarkets, the global PCB market is projected to reach USD 76.68 billion by 2026, up from USD 62.68 billion in 2021, reflecting a significant compound annual growth rate (CAGR) of 4.5%. This growth can be attributed to increasing demands in consumer electronics, automotive industries, and emerging technologies like 5G and IoT, which require advanced PCB solutions.

Innovative technologies such as surface-mount technology (SMT) and automated assembly systems are expected to play crucial roles in enhancing production efficiency. A report from ResearchAndMarkets indicates that the global electronics assembly services market will grow from USD 20.1 billion in 2021 to USD 32 billion by 2026, showcasing a CAGR of 9.2%. These advancements not only contribute to cost reduction but also allow for the manufacturing of more compact and complex designs, enabling greater versatility in product applications. As companies embrace these innovations, the landscape of PCB and assembly production will likely undergo a transformative shift, enhancing the capabilities to meet future market demands.

Related Posts

-

Revolutionizing PCB Printing: Insights from the 138th China Import and Export Fair 2025

-

Innovative Uses in Aerospace and Challenges in Best Circuit Board Fabrication

-

Leading the Way: Unmatched Export Strength of China’s Top PCB Circuit Boards

-

Unlocking Success: The Advantages of Advanced PCB Fabrication Techniques for Global Buyers

-

Innovative Circuit Board Assembly Techniques Shaping the Future of Electronics

-

15 Essential Tips for Efficient Printed Circuit Board Assembly