Top PCB Printing Techniques That Improve Quality and Efficiency Guess Why

In the ever-evolving world of PCB printing, quality and efficiency are paramount. Experts like Dr. Emily Tran, a leading authority in the PCB industry, emphasize, “The future of PCB printing relies on innovative techniques that enhance both precision and speed.” As technology progresses, manufacturers face increasing pressure to deliver superior products while minimizing costs.

Adopting advanced PCB printing techniques can resolve many common challenges. Techniques like direct-to-board printing and inkjet technologies can significantly cut production time. However, there are pitfalls. Not all methods yield consistent quality, and it can be difficult to select the right approach. Companies must navigate these complexities to find solutions that work best for their specific needs.

The path to improvement is not always straightforward. Many manufacturers still struggle with traditional approaches, which can lead to defects and delays. These issues highlight the importance of embracing new PCB printing technologies. Companies must reflect on their current practices and be willing to adapt to enhance their production processes.

Top PCB Printing Techniques That Improve Quality and Efficiency

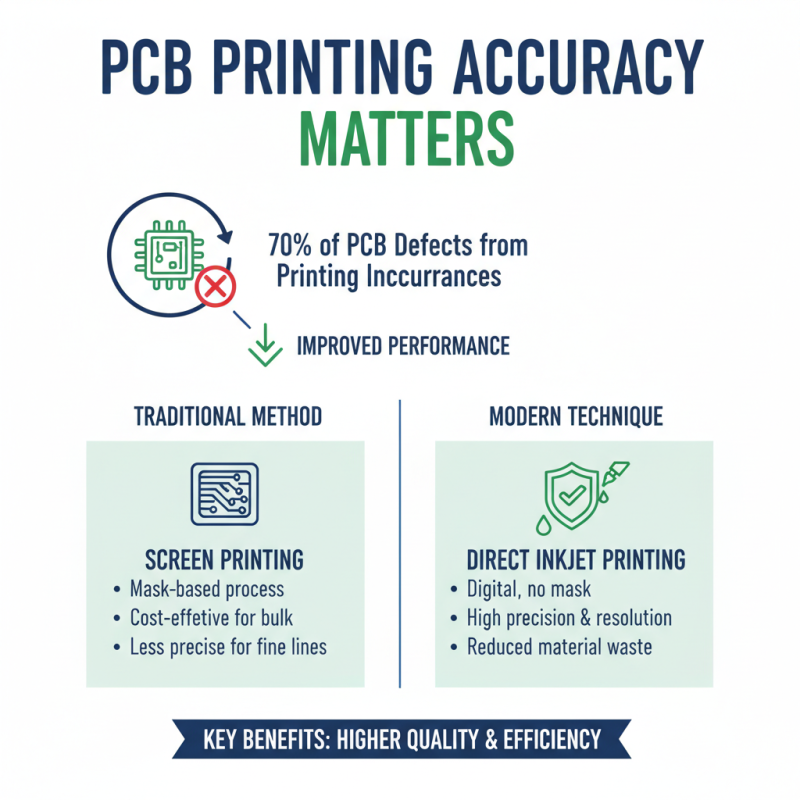

In the world of printed circuit boards (PCBs), efficiency and quality are paramount. Recent industry studies highlight that nearly 70% of PCB defects stem from printing inaccuracies. This shows that adopting the right PCB printing techniques can significantly enhance overall performance. Techniques like direct inkjet printing and screen printing have found increasing favor due to their ability to deliver precise designs with fewer errors.

The rise of digital printing technology is noteworthy. Reports indicate that digital methods can reduce production time by as much as 40%. This not only speeds up processes but also minimizes waste. However, challenges remain. For instance, achieving optimal adhesion in various materials can be complex. Moreover, variations in ink viscosity can lead to inconsistent results. This requires constant adjustment and quality control.

Automated inspection methods can help address these challenges. Studies suggest that implementing these systems can catch up to 90% of printing errors before final assembly. Yet, many manufacturers still rely on traditional methods, missing out on potential improvements. The industry must adapt and innovate to fully leverage these advanced techniques for better efficiency and quality.

Advancements in Inkjet Printing: Benefits and Market Trends in PCB Production

Advancements in inkjet printing have transformed PCB production in recent years. This technology allows for precise layer deposition and reduced material waste. Manufacturers can achieve high resolution with intricate designs. Inkjet printing significantly speeds up the prototyping process. However, inconsistent ink quality can sometimes pose a challenge.

The market trends indicate a growing preference for inkjet methods. Many companies are adopting these systems for their flexibility and efficiency. Yet, the reliance on new materials can lead to unexpected issues. Poor adhesion or ink bleeding may occur if not monitored closely. It’s essential for engineers to refine their techniques continuously. Improvement often comes through trial and error.

Accuracy matters, especially in high-density applications. The need for stringent quality control is apparent. Innovation brings benefits, but it also requires a willingness to adapt. The learning curve can be steep, but the potential rewards are great. Every problem faced provides a chance for further enhancement in the production line.

Comparison of Screen Printing and Laser Printing for High-Resolution PCBs

In modern electronics, PCB manufacturing demands high precision. When comparing screen printing and laser printing, both methods have distinct advantages and challenges. Screen printing has long been favored for its ability to lay down thick, robust layers of conductive material. Industries often report a 20-30% improvement in production speed using this method. However, inconsistency in mesh tension can lead to defects, and achieving high-resolution features remains a challenge.

On the other hand, laser printing offers remarkable resolution, facilitating finer traces and detailed designs. A study highlighted that laser-printed boards can achieve a resolution of up to 20 microns, significantly enhancing component density. However, this technique can struggle with material compatibility. Certain substrates may not bond effectively, causing delamination or poor conductivity. These issues necessitate a careful selection of materials that can withstand the precision of laser technology.

Both methods drive efficiency but require careful consideration. Screen printing boosts throughput, while laser printing excels in precision. As technology evolves, the discussion around integration of both techniques becomes essential. Combining strengths may lead to better quality and efficiency. Understanding these nuances is key for manufacturers aiming to stay competitive in the demanding PCB market.

Impact of Photolithography on PCB Accuracy: Data-Driven Insights

Photolithography remains a cornerstone in PCB manufacturing. This technique directly influences accuracy, achieving high-resolution patterns essential for modern circuits. Reports indicate that precision can reach up to 10 microns in the best setups. This level of detail ensures that components fit perfectly, minimizing errors during assembly.

However, the adoption of photolithography isn't without challenges. The complexity of the process can lead to inconsistencies, particularly with new materials. A recent survey highlighted that nearly 25% of manufacturers reported issues with alignment. These setbacks can increase production time and waste, counteracting efficiency gains.

To address these issues, many companies are turning to data-driven approaches. Implementing real-time monitoring has been shown to improve accuracy by roughly 15%. This proactive stance helps identify potential problems early. Nevertheless, some factories still resist upgrading their processes, relying on outdated methods that may hinder overall productivity. These decisions come at a cost, raising questions about long-term sustainability in an evolving industry.

Emerging Technologies in PCB Printing: Lead Time Reduction and Cost Efficiency

Emerging technologies in PCB printing are transforming the landscape. These advancements focus on reducing lead times and enhancing cost efficiency. For example, innovations in additive manufacturing allow for faster prototyping. The ability to quickly produce high-quality PCBs can significantly impact project timelines.

Moreover, automation in printing processes minimizes human error. This reduces material waste and improves overall efficiency. Techniques like direct write methods eliminate the need for traditional etching. However, not all new technologies yield perfect results. There are still challenges to address, such as compatibility issues with various materials.

Lastly, sustainable practices are becoming vital. Eco-friendly inks are gaining traction. Yet, finding the right balance between cost and quality remains a concern. As the industry evolves, continuous reflection on these practices is necessary for improvement.

Related Posts

-

2025 Top PCB Printing Trends: What You Need to Know for Success

-

Unlocking Success: The Advantages of Advanced PCB Fabrication Techniques for Global Buyers

-

15 Essential Tips for Efficient Printed Circuit Board Assembly

-

Comprehensive Guide to Understanding PCB Circuit Applications and Trends in 2023

-

How to Design and Manufacture a High-Quality Printed Circuit Board from Scratch

-

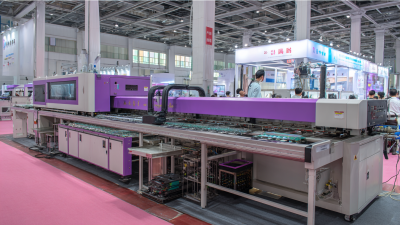

Revolutionizing PCB Printing: Insights from the 138th China Import and Export Fair 2025