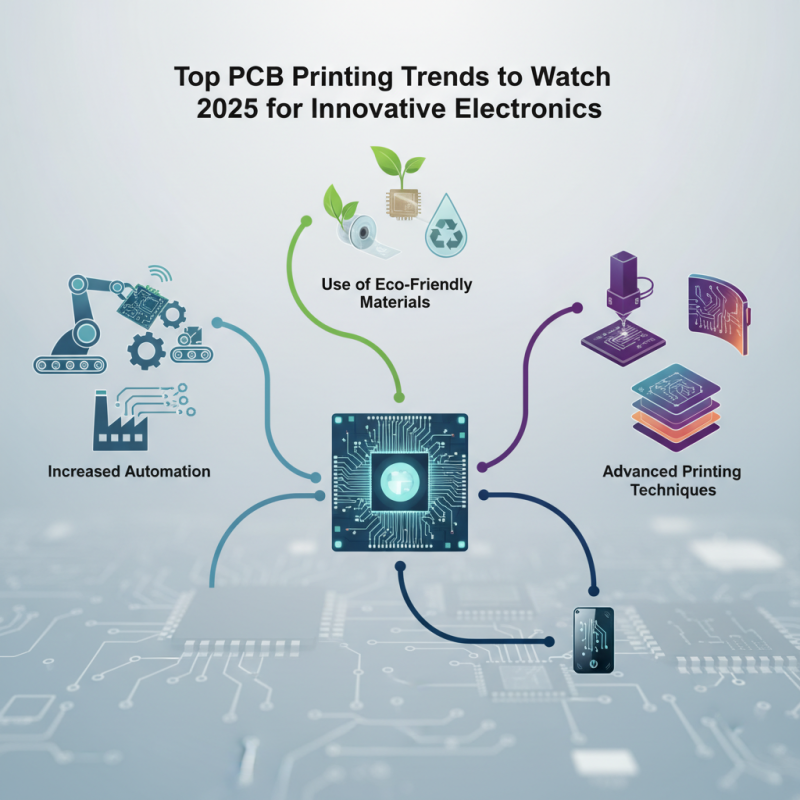

Top PCB Printing Trends to Watch in 2025 for Innovative Electronics

As we approach 2025, the landscape of electronics manufacturing is poised for a dramatic transformation, heavily influenced by advancements in pcb printing technology. This process, essential for the creation of circuit boards, is becoming more sophisticated and is integrating cutting-edge innovations that are redefining the capabilities of electronic devices. From enhancing efficiency to enabling complex designs, the trends in pcb printing are set to shape not only how manufacturers operate but also the functionality and performance of the final products.

Emerging trends such as increased automation, the use of eco-friendly materials, and the adoption of advanced printing techniques highlight the industry's commitment to sustainability and innovation. Companies are increasingly leveraging these trends to streamline production processes and reduce costs while meeting the growing demand for compact, high-performance electronic devices. As we delve deeper into the top pcb printing trends of 2025, it becomes evident that these developments will not only enhance manufacturing capabilities but also pave the way for groundbreaking applications across various sectors, ultimately changing the way we interact with technology.

Emerging Materials in PCB Printing for Enhanced Performance

The printed circuit board (PCB) industry is on the cusp of significant developments, with emerging materials leading the way. In 2025, the focus on miniaturization is set to enhance efficiency and reliability across various sectors. As new materials enter the market, like advanced polymers and nanomaterials, they promise improved electrical performance and durability. This shift is not merely a trend but a necessary evolution to meet the demands of increasingly compact electronic devices.

In parallel, the market for 3D-printed electronics is booming, with projections indicating it could reach USD 5.53 billion by 2034, boasting a compound annual growth rate (CAGR) of over 26%. The flexibility and precision of inkjet printing technology, which currently holds a substantial market share, are driving this growth. As manufacturers seek to optimize their production processes, incorporating these advanced printing methods will become essential.

Tips: When exploring new materials for PCB production, consider their thermal and electrical properties to ensure optimal device performance. Additionally, staying updated on regulatory standards is critical as innovation in electronics continues to accelerate. Embracing these advancements will not only keep manufacturers competitive but also pave the way for groundbreaking applications in the electronics landscape.

Advancements in Automated PCB Manufacturing Processes

Advancements in automated PCB manufacturing processes are set to revolutionize the electronics industry in 2025. As the demand for innovative and compact electronic devices surges, manufacturers are turning to automation to enhance efficiency and precision. The integration of robotics and machine learning into PCB production lines enables faster turnaround times and minimizes human error, leading to higher quality output. Automated systems can adapt to the complexities of modern designs, accommodating various materials and configurations with ease.

Furthermore, these advancements facilitate real-time monitoring and quality control, ensuring that defects are detected early in the production process. This not only reduces waste but also optimizes resource allocation, which is crucial in today's environmentally conscious market. By leveraging automated solutions, companies can achieve scalability, allowing them to respond swiftly to market changes and consumer demands. The future of PCB manufacturing is undoubtedly leaning towards automation, providing a competitive edge to those who embrace these technologies.

Top PCB Printing Trends to Watch in 2025 for Innovative Electronics

| Trend | Description | Impact on Industry | Projected Growth (%) |

|---|---|---|---|

| Advanced Materials | Incorporation of new materials like flexible substrates and high-frequency laminates. | Enhances performance and durability of PCBs in various applications. | 15% |

| Automated Manufacturing | Integration of robotics and AI in PCB manufacturing processes. | Increases efficiency and reduces production costs. | 20% |

| 3D Printing Technology | Utilization of 3D printing for rapid prototyping and production. | Facilitates innovation and customization in PCB designs. | 25% |

| Increased Sustainability | Adoption of eco-friendly materials and processes in PCB production. | Meets regulatory requirements and consumer demand for sustainable products. | 18% |

| Internet of Things (IoT) Integration | Design of PCBs specifically for IoT devices and connectivity. | Supports the growing demand for smart devices and applications. | 30% |

Sustainability Trends in PCB Production and Waste Management

As we look ahead to 2025, sustainability in printed circuit board (PCB) production and waste management will take center stage. The growing environmental consciousness is pushing manufacturers to adopt eco-friendly materials and processes.

Decentralized systems are emerging as a game changer, allowing for localized production and recycling efforts that reduce transportation emissions and energy consumption.

Manufacturers are increasingly focusing on the life cycle of PCBs, promoting designs that facilitate easier disassembly and recycling.

Tips for implementing sustainable PCB practices include embracing intelligent automation, which can streamline both production and waste management processes.

Automating waste sorting can significantly increase recycling rates and reduce landfill contributions. Another essential tip is to actively engage with suppliers who prioritize sustainable practices, ensuring that the entire supply chain aligns with environmental goals.

Finally, investing in research and development of biodegradable materials can pave the way for a more sustainable future, reducing the ecological impact of electronic waste.

By keeping these trends and tips in mind, stakeholders can contribute to a more sustainable electronics industry.

Integration of IoT and Smart Technologies in PCB Design

The integration of IoT (Internet of Things) and smart technologies is set to revolutionize PCB design, offering unprecedented capabilities for innovative electronics in 2025. According to a report by Research and Markets, the global IoT market is expected to reach $1.1 trillion by 2026, driving the demand for more complex and efficient PCB designs. Modern PCBs are evolving to accommodate smart features such as wireless communication, real-time data processing, and enhanced energy efficiency, all of which are crucial for the seamless operation of IoT devices.

One key trend is the adoption of advanced materials, such as flexible substrates that allow for versatile designs. This material innovation enables PCBs to be used in a variety of applications, from wearable technology to smart home devices. Furthermore, smart technologies like AI and machine learning are paving the way for self-adaptive PCB systems that can optimize their functions based on real-time user data and environmental conditions.

**Tips:** When designing for IoT applications, consider using multilayer PCBs to accommodate the increased density of circuits. Additionally, invest in simulation tools to analyze the thermal performance of your PCB, ensuring that the integration of smart technologies doesn’t compromise reliability. Lastly, stay updated with advancements in secure PCB design to protect sensitive data in interconnected devices.

Top PCB Printing Trends in 2025

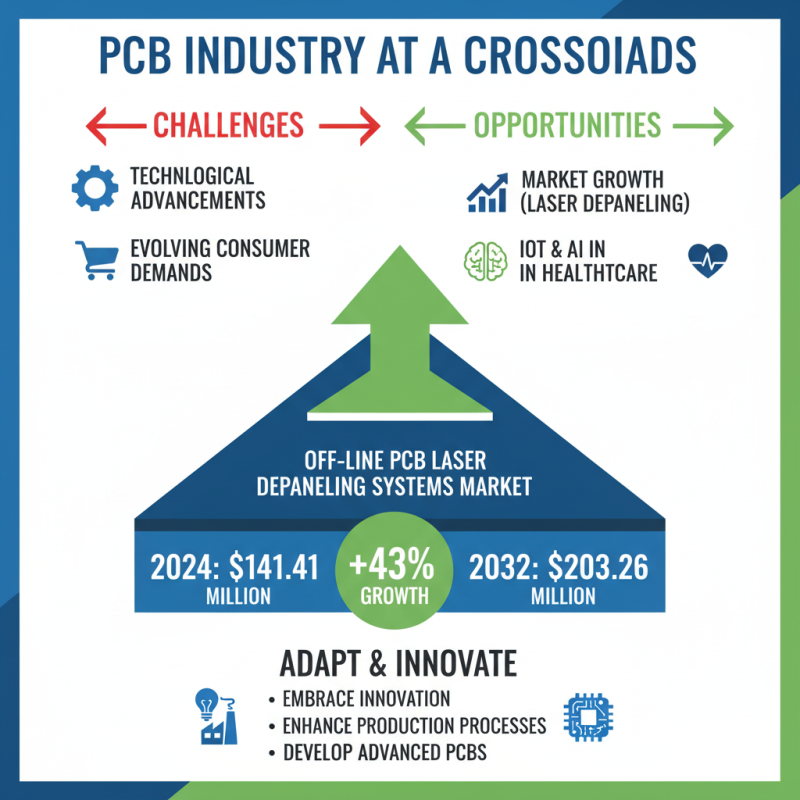

Future Challenges and Opportunities in the PCB Industry

The PCB industry is at a crossroads, with technological advancements and evolving consumer demands presenting both challenges and opportunities. As the market for off-line PCB laser depaneling systems is projected to grow from $141.41 million in 2024 to $203.26 million by 2032, businesses must adapt to this growth by embracing innovation and enhancing production processes. The integration of IoT and AI in healthcare is reshaping service delivery, pushing manufacturers to develop PCBs that support these sophisticated technologies.

Tips: To stay competitive, focus on investing in research and development to enhance PCB designs that cater to emerging needs. Also, consider forming strategic partnerships to leverage advanced manufacturing techniques that can reduce lead times and costs.

With ongoing trade tensions, especially between the U.S. and China, PCB manufacturers face significant uncertainty. Companies must be agile, re-evaluating supply chains and exploring new markets to mitigate risks. Emphasizing sustainability and efficiency in production will not only reduce vulnerabilities but also align with global trends towards eco-friendly practices.

Tips: Implementing automation and smart manufacturing solutions can significantly improve efficiency. Regularly monitor industry trends to identify potential opportunities in niche markets, such as AI and 5G applications, that drive demand for printed circuit boards.

Related Posts

-

Unveiling PCB and Assembly Innovations at the 138th China Import and Export Fair 2025

-

Leading the Way: Unmatched Export Strength of China’s Top PCB Circuit Boards

-

Innovative Uses in Aerospace and Challenges in Best Circuit Board Fabrication

-

Innovative Circuit Board Assembly Techniques Shaping the Future of Electronics

-

Unlocking Success: The Advantages of Advanced PCB Fabrication Techniques for Global Buyers

-

How to Design and Manufacture a High-Quality Printed Circuit Board from Scratch