Leading the World with Premium Heavy Copper PCBs from China's Best Manufacturers

The demand for heavy copper PCBs is rapidly rising as advanced electronic applications require enhanced performance and reliability. According to a recent market research report by Mordor Intelligence, the global PCB market is projected to reach USD 81.75 billion by 2026, with heavy copper PCBs being a significant segment due to their ability to handle high current applications.

As industries increasingly adopt technologies such as electric vehicles and renewable energy systems, the need for durable, efficient, and high-power circuit solutions becomes paramount. This blog will explore top strategies employed by Chinese manufacturers, renowned for their innovative approaches and superior production capabilities in the heavy copper PCB sector, demonstrating how they are leading the world in this critical technology.

Advantages of After-Sales Service in Heavy Copper PCB Manufacturing

In the realm of heavy copper PCB manufacturing, after-sales service plays an essential role in enhancing product longevity and performance. As the electronics industry moves towards a circular economy, manufacturers are increasingly recognizing that the lifespan of their products directly impacts consumer satisfaction and environmental sustainability.

High-quality after-sales support not only addresses immediate technical issues but also fosters a long-term relationship between manufacturers and their clients. This commitment can lead to improved designs and enhanced PCB performance, ultimately benefiting both parties.

Moreover, with the recent success of industry events like the CCIE-2025SMM Copper Conference, the importance of after-sales service in maintaining competitive advantage has been underscored. As manufacturers share insights and innovations, it becomes clear that strong after-sales support is crucial for navigating the complex landscape of heavy copper PCB production.

By investing in comprehensive service programs, companies can ensure that their products meet customer expectations while contributing to a more sustainable electronic ecosystem, aligning with the growing demand for durable and reliable electronics in the market.

Cost-Effective Repair Strategies for Heavy Copper PCB Systems

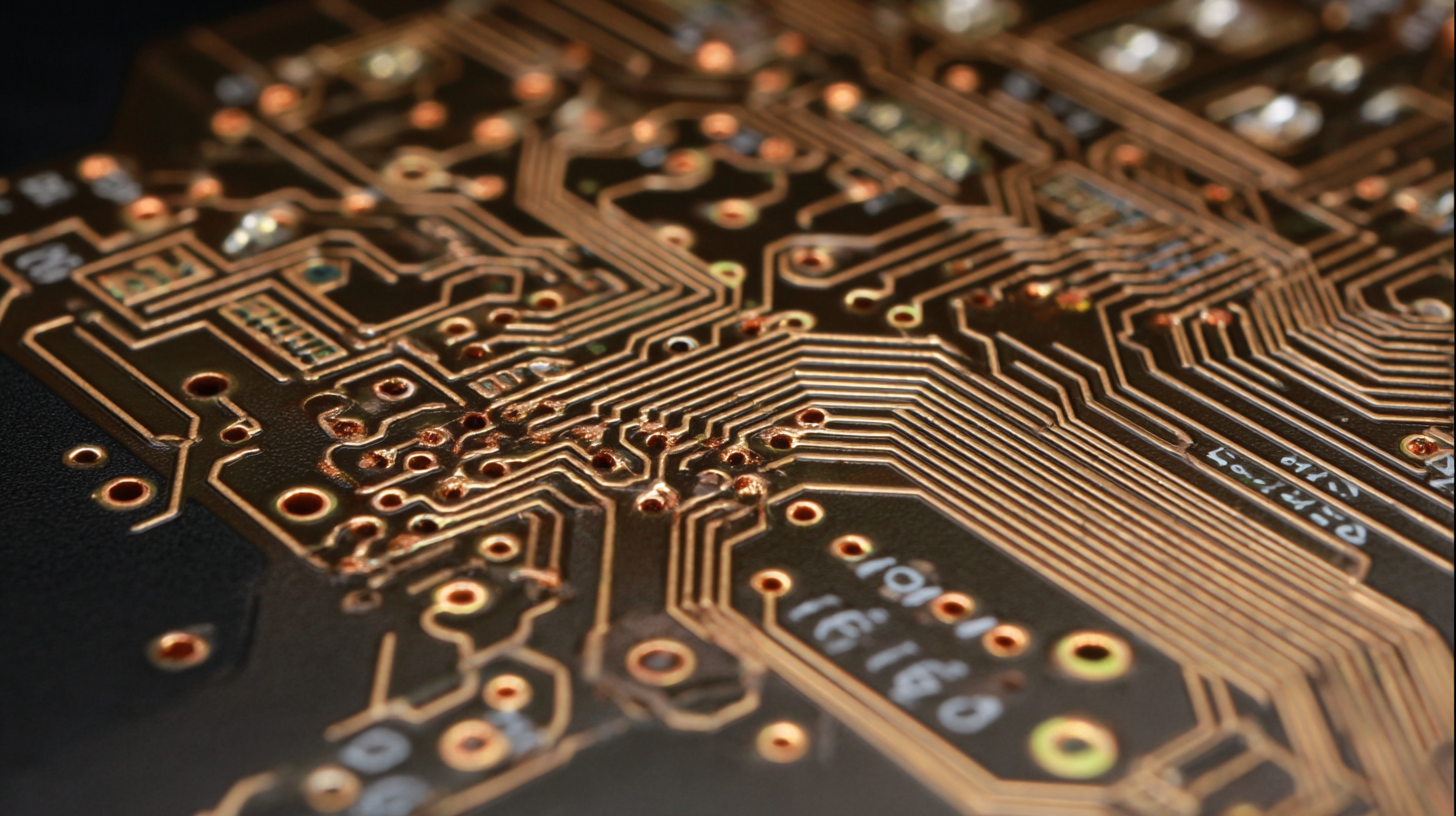

When dealing with heavy copper PCB systems, cost-effective repair strategies are essential to prolong the life of these critical components. Heavy copper PCBs are known for their superior heat dissipation and current carrying capabilities, but when they face issues such as circuit failures or thermal damage, implementing smart repair solutions can significantly reduce operational downtime and expenses.

One effective tip for maintaining heavy copper PCBs is to regularly inspect and clean the boards to prevent oxidation and dirt buildup that can lead to conductivity issues. Additionally, using thermal imaging cameras can help identify heat spots before they become critical, allowing for preemptive maintenance. For any necessary repairs, employing compatible materials that match the original copper thickness ensures optimal performance and longevity during the reparative process.

Another practical approach involves training staff on the nuances of heavy copper PCB systems. By equipping teams with the right knowledge, they can identify potential problems early on and apply timely, adequate repairs. This proactive stance not only minimizes repair costs but also enhances the overall reliability of the PCB systems, allowing manufacturers to focus on innovation rather than constant maintenance.

Maximizing Performance through Quality After-Sales Support

In today's competitive electronics landscape, the performance and reliability of printed circuit boards (PCBs) are paramount. Heavy copper PCBs, known for their superior conductivity and enhanced thermal management, are increasingly favored in high-performance applications. However, purchasing high-quality PCBs from top manufacturers in China is only the beginning of a successful project. Equally significant is the quality of after-sales support, which can greatly influence the overall performance and longevity of the electronic systems.

Robust after-sales support enhances customer satisfaction and fosters long-term partnerships. Manufacturers who prioritize quality support provide invaluable assistance in troubleshooting, design modifications, and timely maintenance. This proactive approach ensures that any issues are resolved quickly, minimizing downtime and optimizing performance. With a dedicated support team, clients can confidently innovate and push the boundaries of technology, knowing they have expert guidance to navigate challenges that arise post-purchase.

Moreover, comprehensive after-sales services can facilitate continuous improvement. Through feedback loops and performance assessments, manufacturers can refine their processes and adapt to evolving market demands. This synergy between high-quality products and exceptional support positions heavy copper PCBs as a leader in the industry, empowering businesses to achieve their goals efficiently and effectively.

Understanding Common Repair Challenges for Heavy Copper PCBs

Heavy copper PCBs, known for their superior thermal conductivity and durability, present unique challenges, especially in high-performance applications like GPUs. Recent reports have highlighted a troubling trend among advanced graphics cards, where issues such as cracking around PCIe slots have become alarmingly common. This raises critical concerns for both manufacturers and users, as the integrity of heavy copper PCBs can significantly influence overall device performance and lifespan.

The reported failures of high-end GPUs illustrate the vulnerability of these complex components when subjected to physical stress. Upon receiving damaged units, many repairs have been categorized as "no fix" cases due to severe PCB fractures. This underscores the necessity for improved design standards and robust manufacturing techniques. As the demand for powerful computing continues to grow, manufacturers must address these repair challenges by focusing on the structural integrity of heavy copper PCBs, ensuring they withstand the rigors of modern technology without compromising reliability.

Challenges and Repair Frequencies in Heavy Copper PCBs

The Role of Customer Feedback in Enhancing PCB Services

Customer feedback plays a crucial role in enhancing the services offered by PCB manufacturers, especially in the competitive landscape of heavy copper PCBs. The global electronic manufacturing services market size is projected to grow from $648.11 billion in 2025 to $1,033.17 billion by 2032, reflecting a robust CAGR of 6.9%. This growth is driven by increasing demand for high-quality PCBs across various applications, from consumer electronics to automotive industries. Manufacturers that actively seek and implement customer feedback are better positioned to address market needs, innovate their processes, and improve product quality.

Furthermore, initiatives such as providing free design consultancy services highlight the importance of client collaboration in the PCB sector. By engaging with customers and understanding their pain points, manufacturers can refine their service delivery and enhance customer satisfaction. Continuous investments in technology and resources are vital as seen in recent developments within the industry, where companies are capitalizing on feedback to streamline production times and optimize service offerings. Such proactive strategies not only foster customer loyalty but also drive significant advancements in the evolving PCB landscape.