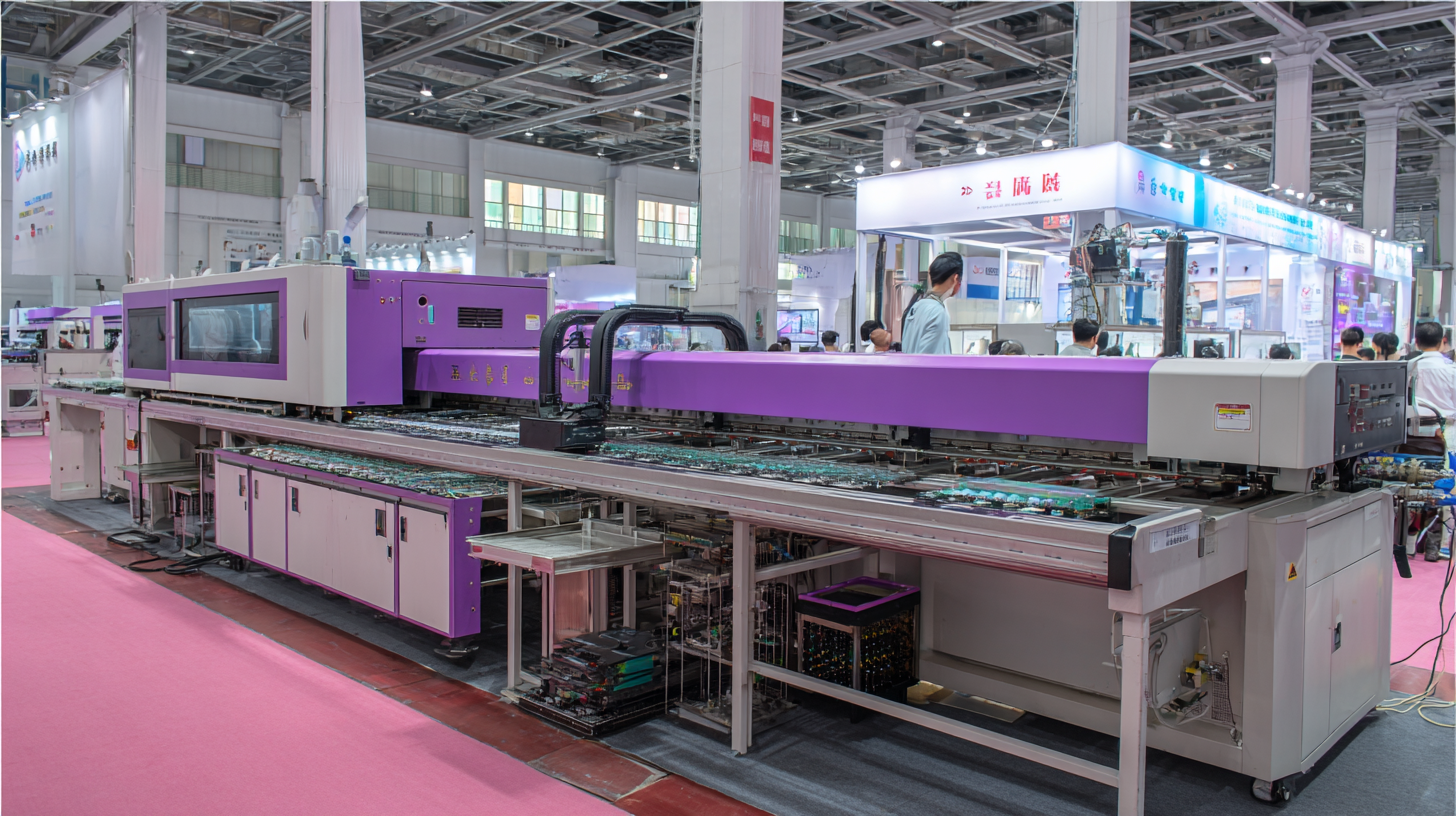

Revolutionizing PCB Printing: Insights from the 138th China Import and Export Fair 2025

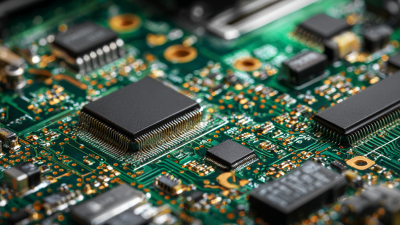

The 138th China Import and Export Fair in 2025 serves as a pivotal platform for showcasing advancements in various industries, particularly in the realm of PCB printing. With the global PCB market projected to reach approximately $75 billion by 2027, driven by the accelerating demand for electronics in sectors such as automotive and telecommunications, innovations in PCB printing technology are more crucial than ever.

This year's fair presents groundbreaking insights into state-of-the-art processes, materials, and equipment that promise to enhance efficiency and sustainability in PCB manufacturing. As reported by industry analysts, adopting advanced PCB printing methods can reduce production time by up to 30% while maintaining high precision levels, marking a significant leap forward in the quest for smarter, more reliable electronic components.

This year's fair presents groundbreaking insights into state-of-the-art processes, materials, and equipment that promise to enhance efficiency and sustainability in PCB manufacturing. As reported by industry analysts, adopting advanced PCB printing methods can reduce production time by up to 30% while maintaining high precision levels, marking a significant leap forward in the quest for smarter, more reliable electronic components.

Trends in PCB Printing Technologies Showcased at the 138th China Import and Export Fair

At the 138th China Import and Export Fair, the latest trends in PCB printing technologies were prominently showcased, reflecting significant advancements in the field. Exhibitors presented innovative techniques that enhance the efficiency and precision of PCB manufacturing. These technologies aim to meet the growing demand for high-performance printed circuit boards in various applications, including consumer electronics, automotive, and telecommunications.

Industry leaders highlighted the integration of automation and smart manufacturing processes, which are revolutionizing PCB production. The use of advanced materials and sustainable practices was also a focal point, addressing environmental concerns while improving the longevity and reliability of PCBs. As suppliers gather insights from these trends, the future of PCB printing looks promising, with a clear trajectory towards more efficient and eco-friendly solutions.

Innovations in Materials and Processes for Enhanced PCB Manufacturing

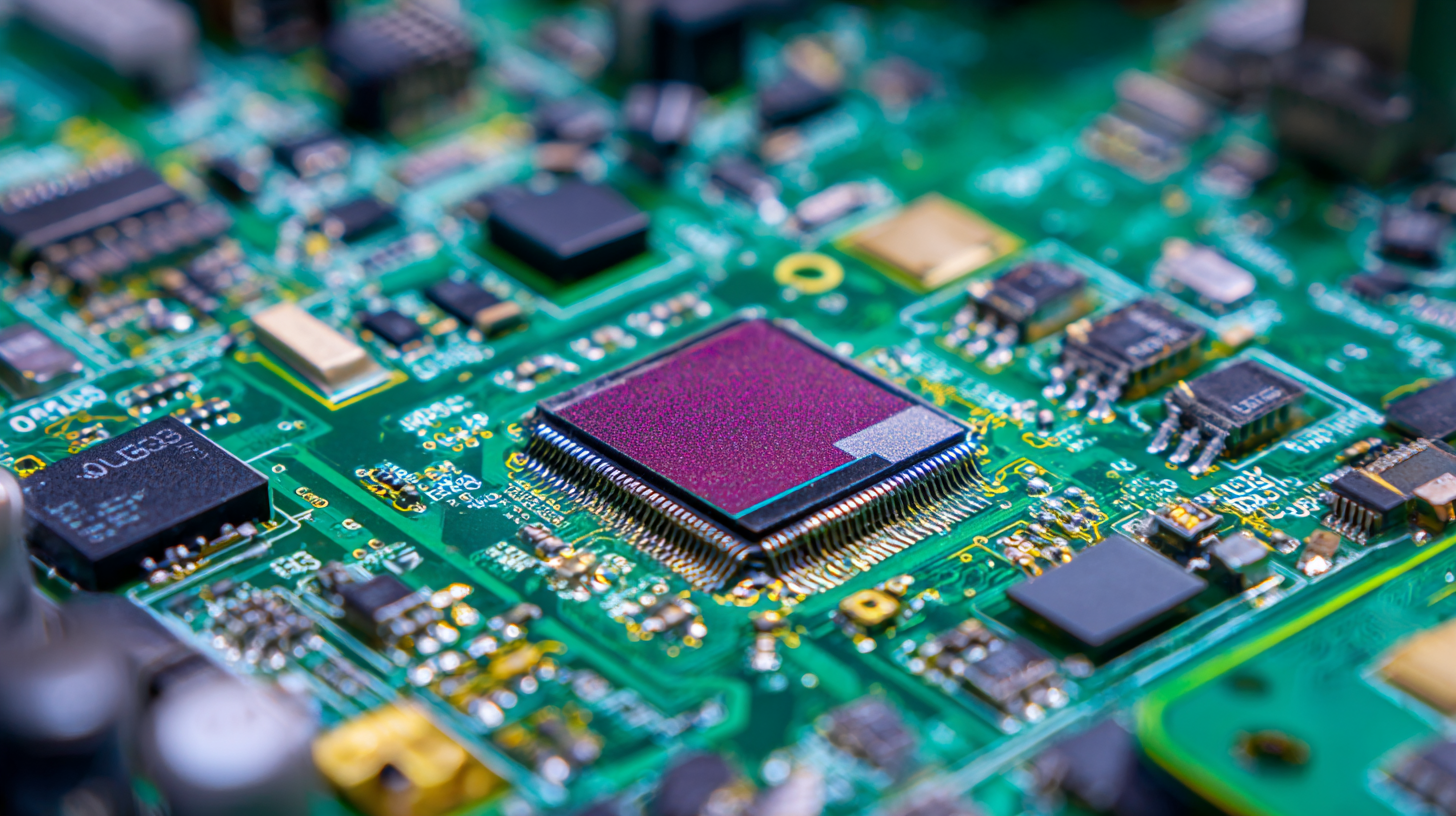

The 138th China Import and Export Fair 2025 showcased groundbreaking innovations in materials and processes that promise to redefine PCB (Printed Circuit Board) manufacturing. Recent reports indicate that the global PCB market is projected to reach $100 billion by 2025, driven by advancements in technology and increasing demand for electronic devices. Among the featured innovations were eco-friendly materials that not only reduce environmental impact but also improve the thermal and electrical performance of PCBs. These new substrates allow for enhanced miniaturization and integration of additional functionalities, which are crucial as the industry progresses towards more compact and efficient designs.

Incorporating advanced manufacturing techniques such as additive manufacturing and automated assembly processes has also emerged as a focal point. These techniques significantly reduce production times and costs while enhancing precision and scalability. A report from the IPC (Institute of Printed Circuits) highlights that companies adopting these cutting-edge processes can achieve up to 30% cost savings and improve production efficiency by 25%.

**Tips:** To remain competitive, PCB manufacturers should consider investing in research and development to explore emerging materials like bio-based resins and nanomaterials. Additionally, staying informed about automation technologies will be key in optimizing production lines. Regular trials and pilot programs with these new processes can lead to insightful data, ultimately driving innovation forward.

Revolutionizing PCB Printing: Innovations in Materials and Processes

This chart displays the advancements in various materials used in PCB manufacturing over the past years, showcasing their adoption rates and effectiveness in enhancing production efficiency.

Key Players and Partnerships Transforming the PCB Printing Landscape

The 138th China Import and Export Fair 2025 has emerged as a pivotal platform for unveiling innovations in PCB printing technology. Major players in the electronics manufacturing sector are forging strategic partnerships that are reshaping the landscape of PCB fabrication. For instance, a report by ResearchAndMarkets indicates that the global PCB market is projected to reach $80 billion by 2025, driven by advancements in manufacturing techniques and increasing demand for compact electronic devices. This surge in market size is prompting manufacturers to collaborate more closely with technology providers to enhance production efficiency and sustainability.

Companies such as Jabil and PCB Solutions are leading the charge by integrating advanced materials and automation into their production lines. Their partnerships with software developers aim to create a more streamlined design-to-manufacturing process, significantly reducing time-to-market for new products. As highlighted by a recent IPC report, nearly 60% of PCB manufacturers are investing in smart technologies, positioning them to meet the evolving needs of industries—from automotive to consumer electronics. These collaborations not only facilitate innovation but also enhance competitiveness in a rapidly changing market environment.

Sustainability Practices in PCB Printing Highlighted at the Fair

At the 138th China Import and Export Fair 2025, sustainability in PCB printing emerged as a pivotal theme, reflecting the industry's growing commitment to environmental responsibility. As consumer microelectronics proliferate, the spotlight is increasingly on their life cycle impacts. The fair highlighted innovative practices, such as the adoption of circular economy principles and life cycle assessments (LCA) aimed at minimizing ecological footprints. These strides are crucial as manufacturers seek to align with global sustainability goals.

One of the key methods discussed was in-situ mechanical and chemical etching, which presents a milder hydrometallurgical approach for the recovery of valuable metals like gold, nickel, and copper from printed circuit boards. This technique not only enhances resource recovery efficiency but also reduces energy consumption, showcasing a significant leap toward greener PCB assembly materials. Such advancements indicate a proactive shift in the industry to incorporate eco-friendly practices while addressing the challenges posed by electronic waste, ultimately contributing to a more sustainable future in electronics manufacturing.

Future Directions for the PCB Industry Post-2025 Exhibition Insights

The PCB industry is poised for significant transformation as showcased at the 138th China Import and Export Fair in 2025. With advancements in technology and a growing demand for innovative applications, future directions for the industry are becoming increasingly clear. One of the key trends identified is the move towards automation and smart manufacturing processes. By integrating AI and machine learning, manufacturers can enhance production efficiency, reduce errors, and improve overall quality of printed circuit boards.

Another vital insight from the exhibition is the emphasis on sustainability and eco-friendly practices. As environmental concerns grow, the PCB industry is shifting towards the adoption of green materials and processes. This shift not only addresses regulatory pressures but also meets consumer demand for environmentally responsible products. Future developments may include the creation of biodegradable PCB materials and recycling initiatives, which will play a crucial role in minimizing the environmental impact of production practices.

Additionally, collaboration between industry players and academic institutions is expected to drive innovation in PCB design and functionality. The exchange of knowledge and resources will lead to the development of next-generation PCBs that support emerging technologies such as 5G, IoT, and AI applications. As the landscape evolves, staying ahead in research and development will be essential for companies aiming to maintain competitive advantages in the dynamic PCB market.

Related Posts

-

Innovative Uses in Aerospace and Challenges in Best Circuit Board Fabrication

-

Unlocking Success: The Advantages of Advanced PCB Fabrication Techniques for Global Buyers

-

Leading the Way: Unmatched Export Strength of China’s Top PCB Circuit Boards

-

Innovative Circuit Board Assembly Techniques Shaping the Future of Electronics

-

15 Essential Tips for Efficient Printed Circuit Board Assembly

-

Comprehensive Guide to Understanding PCB Circuit Applications and Trends in 2023