Solutions for Streamlined Best Circuit Board Assembly: Achieving Excellence in Production

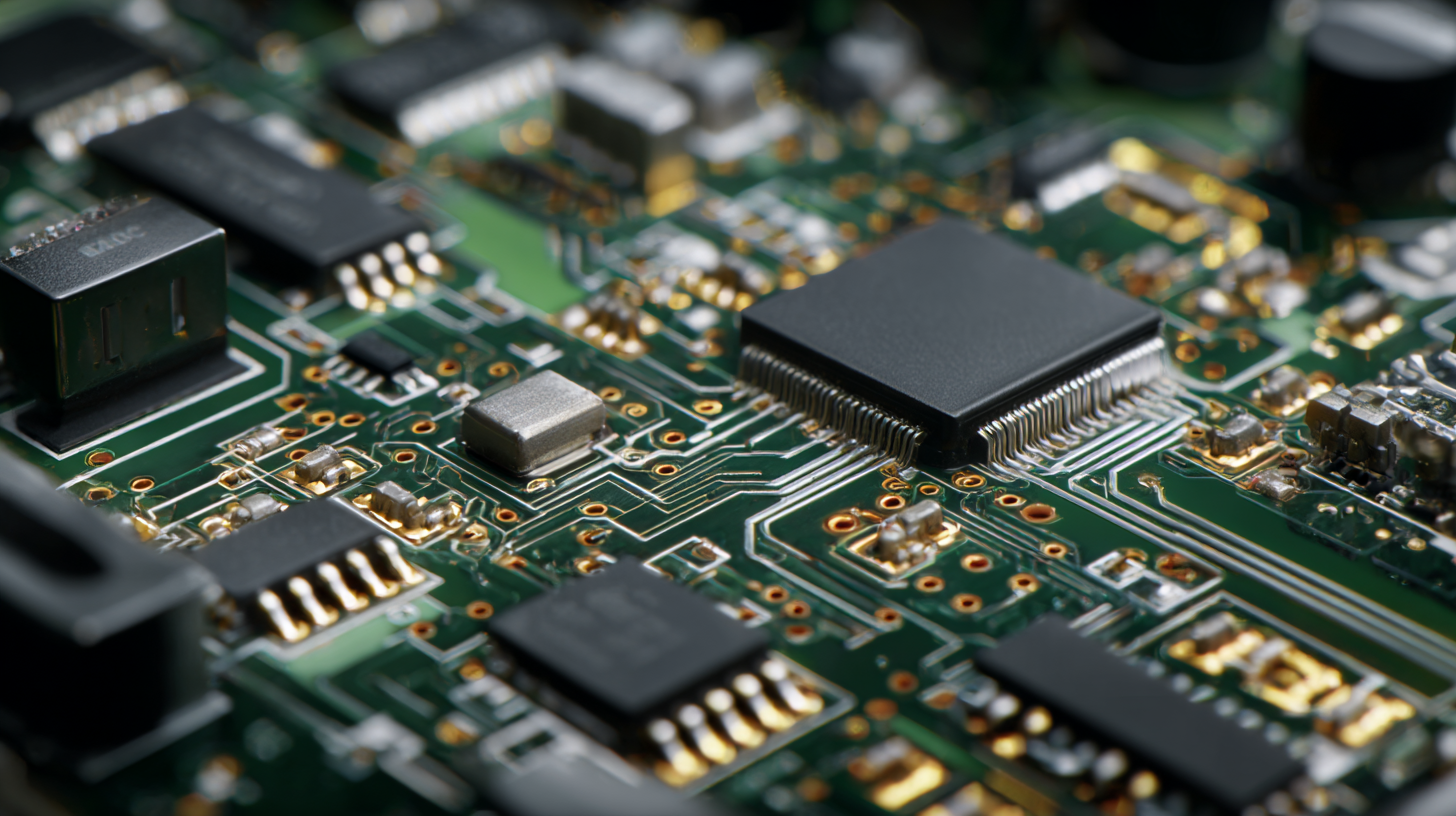

In an increasingly competitive global market, the demand for high-quality circuit board assembly (CBA) continues to rise, with industry reports indicating that the CBA market is expected to reach $30 billion by 2025. This growth is fueled by advancements in technology across various sectors, including consumer electronics, automotive, and medical devices, where precision and reliability are paramount.

As manufacturers strive to achieve excellence in production, adopting streamlined solutions for circuit board assembly becomes essential. Leading factories recognized for their superior output not only meet compliance standards but also leverage automation and efficient workflows, significantly reducing production costs and time. By implementing best practices in CBA, manufacturers position themselves at the forefront of the industry, ready to serve an ever-expanding international clientele.

As manufacturers strive to achieve excellence in production, adopting streamlined solutions for circuit board assembly becomes essential. Leading factories recognized for their superior output not only meet compliance standards but also leverage automation and efficient workflows, significantly reducing production costs and time. By implementing best practices in CBA, manufacturers position themselves at the forefront of the industry, ready to serve an ever-expanding international clientele.

Best Practices for Designing High-Quality Circuit Boards: Key Technical Specifications and Guidelines

When it comes to designing high-quality circuit boards, adhering to key technical specifications is crucial for ensuring optimal performance and reliability. One essential guideline is to maintain appropriate trace width and spacing, which impacts current carrying capacity and signal integrity. Engineers should use calculated formulas to determine the necessary dimensions based on the intended electrical load and environmental factors. Additionally, proper layer stacking is vital for minimizing electromagnetic interference and maximizing signal integrity, ensuring that the board operates efficiently under various conditions.

Another best practice involves the selection of suitable materials. High-quality substrates like FR-4 or Rogers can significantly enhance the thermal and electrical performance of a circuit board. It's also important to consider component placement and routing strategies early in the design process. By strategically positioning components, designers can reduce trace lengths, thereby decreasing resistance and improving thermal management. Furthermore, implementing design for manufacturability (DFM) principles can facilitate smoother production processes, ultimately leading to higher-quality outcomes in circuit board assembly.

Understanding the Role of Materials in Circuit Board Assembly: Impact on Performance and Reliability

The role of materials in circuit board assembly is pivotal, influencing both performance and reliability. In the era of rapid technological advancements, especially with the rise of AI and interconnected devices, the choice of materials used in packaging and assembly becomes crucial. Advanced polymer materials with improved thermal conductivity are essential for the optimal performance of microchips, particularly in the face of the demanding requirements of the 5G landscape. Traditional materials often fail to provide adequate heat dissipation, which can lead to the failure of sensitive electronic components.

Moreover, as the electronics industry trends toward miniaturization, the reliability of electronic micro-assemblies takes center stage. Implementing innovative bonding materials that enhance mechanical support and thermal management is becoming a necessity. As manufacturers strive to meet the increasing expectations for compact and high-performing electronics, the significance of material properties will undoubtedly shape the future of circuit board assembly practices. The integration of digital technologies to simulate and optimize these materials further enhances the potential for innovative solutions in the industry, ensuring that production quality meets the rigorous demands of modern applications.

Solutions for Streamlined Best Circuit Board Assembly: Achieving Excellence in Production

| Material Type | Performance Impact | Reliability Factor | Common Applications |

|---|---|---|---|

| FR-4 | Good electrical insulation; low moisture absorption | High thermal stability, long lifespan | Consumer electronics, automotive |

| Flex PCB | Flexible structure; lightweight | Moderate durability, susceptible to wear | Wearable devices, mobile phones |

| Ceramic | Excellent heat resistance; low dielectric loss | Very high reliability, suited for harsh environments | Aerospace, military applications |

| Aluminum | Good thermal conductivity; lightweight | High resistance to corrosion | LED lighting, power electronics |

| Polyimide | High operating temperature; excellent mechanical properties | Outstanding chemical resistance | Aerospace, high-performance computing |

Automation in Circuit Board Production: Enhancing Efficiency through Advanced Technologies

In the realm of circuit board assembly, automation stands at the forefront of revolutionizing production efficiency. According to a report by IPC, the global market for automated assembly equipment is projected to reach $11 billion by 2026, growing at a CAGR of 6.5%. This significant rise underscores the industry's impact on reducing labor costs and enhancing precision in manufacturing processes. Automation not only minimizes human error but also accelerates production speed, leading to more rapid time-to-market for new electronic devices.

Advanced technologies such as AI-driven robotics, machine vision systems, and IoT integration are pivotal in optimizing circuit board production. A study by Deloitte highlighted that manufacturers integrating such technologies can achieve productivity gains of up to 30%. By leveraging these innovations, companies are able to monitor production in real time, ensuring optimal workflow and addressing any bottlenecks proactively. Additionally, the introduction of automated quality inspection processes enhances the reliability of finished products, thereby boosting customer satisfaction and reducing return rates. In a competitive landscape, adopting automated solutions is not just a trend; it is a strategic necessity for achieving excellence in circuit board assembly.

Solutions for Streamlined Best Circuit Board Assembly

This chart illustrates the production efficiency percentages achieved through different assembly methods in circuit board production. The transition from manual to fully automated assembly demonstrates significant improvements in efficiency.

Quality Control Measures in Circuit Board Assembly: Ensuring Consistency and Reducing Defects

Quality control is crucial in circuit board assembly, as it directly impacts the performance and reliability of electronic devices. One of the key measures to ensure consistency and reduce defects is the implementation of rigorous inspection processes throughout the production stages. Regular audits and assessments can help identify areas for improvement, leading to enhanced product quality and customer satisfaction.

Tips: Establish a robust inspection protocol that includes both automated and manual checks. Utilize advanced imaging technology for precise inspections, and empower employees to report any irregularities they observe during production. This proactive approach encourages a culture of quality and accountability within the team.

Furthermore, adopting standardized assembly procedures can significantly reduce variability and defects. By training staff on best practices and conducting regular workshops, teams can stay updated on the latest techniques and technologies in circuit board assembly.

Tips: Create a comprehensive training manual that outlines all assembly processes and quality standards. Incorporate real-time feedback mechanisms where employees can suggest modifications based on their experiences, fostering continuous improvement and innovation throughout the assembly line.

The Future of Circuit Board Assembly: Trends and Innovations Shaping the Industry

The landscape of circuit board assembly is rapidly evolving, driven by innovative technologies and trends that are reshaping the industry. One of the most significant trends is the rise of automation and smart manufacturing. With increasing demands for efficiency and precision, manufacturers are turning to automated processes that utilize robotics and artificial intelligence. This shift not only enhances production speed but also ensures higher quality output, minimizing human error and operational costs.

Moreover, sustainability is becoming a pivotal focus in electronics manufacturing. Companies are exploring eco-friendly materials and practices to reduce waste and energy consumption. The adoption of greener technologies not only meets regulatory standards but also caters to a growing consumer base that prioritizes environmentally responsible products. As firms implement these sustainable practices, they're also benefiting from increased brand loyalty and market differentiation.

As we look to the future, the emergence of startups in this space signifies a dynamic evolution. Emerging companies are pioneering novel solutions, from advanced materials to innovative assembly techniquesthat contribute significantly to the industry's transformation. Staying abreast of these trends can empower businesses to adapt and thrive in a competitive environment, ensuring they remain at the forefront of circuit board assembly excellence.