Top 10 PCB Electronics Trends You Need to Know About?

The realm of pcb electronics is evolving rapidly. Industry reports indicate a significant growth trend, with the global PCB market expected to reach $81 billion by 2028. This surge is driven by advancements in various electronics sectors, including IoT, automotive, and telecommunications. Companies are investing heavily to stay competitive, pushing the boundaries of what’s possible with printed circuit boards.

Key trends are emerging within pcb electronics. Flexible PCBs are gaining traction due to their versatility in modern devices. Additionally, the demand for miniaturization is driving innovations. Yet, challenges remain. Manufacturing processes must adapt to ensure quality and efficiency. The industry faces pressure from environmental concerns as well. As technologies evolve, sustainability will be crucial for future growth.

Understanding these trends is essential for professionals in the sector. Those who adapt swiftly can leverage new opportunities. However, the complexity of the industry may cause uncertainty. Companies must reflect on their strategies and embrace change to thrive in this competitive landscape.

Emergence of Flexible Printed Circuit Boards in Modern Electronics

Flexible Printed Circuit Boards (FPCBs) are becoming a cornerstone of modern electronics. Their adaptability allows for innovative designs in various applications, ranging from smartphones to wearable devices. According to a recent industry report, the global flexible PCB market is expected to reach USD 43.1 billion by 2027, growing at a compound annual growth rate (CAGR) of 10.9%. This growth is driven by increased demand for lightweight and compact electronics.

The benefits of FPCBs are clear. They offer significant space savings due to their thin and lightweight nature. Additionally, they enhance design flexibility, allowing for complex configurations. However, the production process is intricate and prone to issues. Manufacturers may face challenges with material quality and consistency. Moreover, as the technology evolves, there is a constant need to balance cost and performance. A Trade Association report noted that about 30% of flexible PCB production encounters defects, raising questions about long-term reliability.

Despite these challenges, the rise of FPCBs cannot be ignored. They push the boundaries of what's possible in electronic design. As industries continue to innovate, flexible circuits will likely play an essential role. Companies are investing in research and development to improve manufacturing techniques. But, as the market grows, so does the need for sustainable practices. There is a pressing requirement for eco-friendly materials and processes, reflecting a broader trend towards sustainability in electronics.

Top 10 PCB Electronics Trends You Need to Know About

| Trend | Description | Impact | Applications |

|---|---|---|---|

| Flexible Printed Circuit Boards | Increase in demand for flexible designs allowing for compact and lightweight electronics. | Enhances portability and integration in various devices. | Wearable devices, smartphones, and tablets. |

| High-Density Interconnection (HDI) | Utilization of microvias to create more paths on smaller boards for complex circuits. | Improves performance and reduces size. | Smartphones, tablets, and IoT devices. |

| 3D Printing of PCBs | Enables rapid prototyping and production of complex PCB geometries. | Reduces time-to-market and costs. | Prototyping and niche electronic applications. |

| Internet of Things (IoT) Integration | PCBs designed specifically for smart devices with connectivity features. | Boosts the functionality of household and industrial electronics. | Smart home devices, industrial automation, and health monitoring. |

| Eco-Friendly PCBs | Trends toward sustainable materials and processes in PCB manufacturing. | Reduces environmental impact and meets regulatory standards. | Consumer electronics, automotive, and renewable energy sectors. |

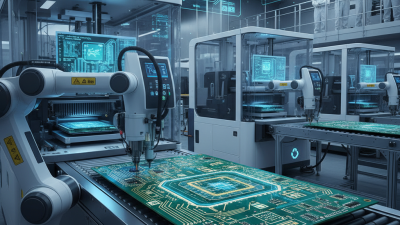

| Smart Manufacturing | Implementation of AI and automation in PCB production. | Increases efficiency and quality in production processes. | All sectors of electronic manufacturing. |

| Miniaturization | Continued trend towards smaller, more compact PCB designs. | Enables the creation of slimmer and lighter products. | Wearable tech and compact consumer electronics. |

| High-Speed PCBs | Designs that support higher frequencies and data rates. | Improves performance in data-intensive applications. | Telecommunications and high-performance computing. |

| Integration of AI and Machine Learning | Utilization of AI for design automation and fault detection. | Enhances problem-solving efficiency and accuracy. | All electronic design sectors. |

| Digital Twins Technology | Creation of digital replicas for monitoring and testing PCB designs. | Optimizes design processes and maintenance. | All electronic industries. |

Integration of Internet of Things (IoT) in PCB Design and Manufacturing

The integration of the Internet of Things (IoT) in PCB design is transforming the electronics landscape. In 2022, the global IoT market was valued at approximately $389 billion. Predictions indicate it could reach over $1 trillion by 2026. This rapid growth highlights the demand for smart devices. PCBs must evolve to meet these needs, involving more complex designs and compact models.

IoT devices require specialized PCBs that support connectivity. This includes Wi-Fi, Bluetooth, and more. These technologies enable devices to communicate effectively. However, integrating these features introduces challenges. Manufacturers must ensure reliability and performance without increasing costs significantly. A report revealed that nearly 70% of manufacturers experience difficulties in optimizing PCB designs for IoT applications.

Another pressing issue is data management. IoT devices generate vast amounts of data. Properly managing this data on PCBs is essential for seamless operation. Effective data processing ensures faster responses and improved functionality. Yet, many manufacturers struggle to integrate adequate data handling capabilities within traditional PCB frameworks. This friction can hinder innovation. It's crucial to address these challenges to fully leverage IoT potential in the PCB sector.

Top 10 PCB Electronics Trends: Integration of IoT in PCB Design and Manufacturing

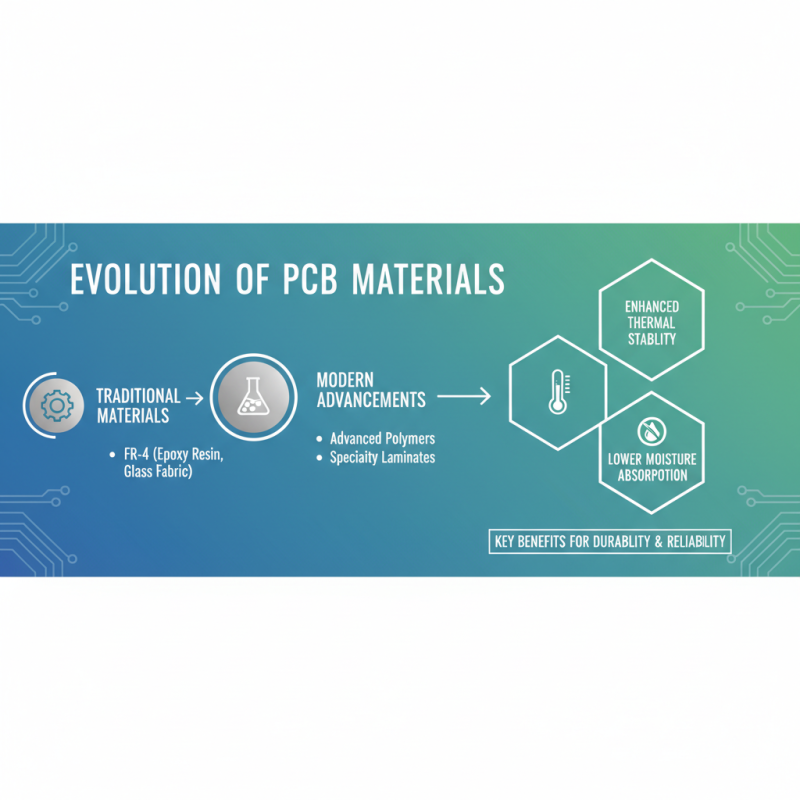

Advancements in PCB Materials for Enhanced Performance and Durability

The evolution of PCB materials has been significant. Advances in polymers and laminates are noteworthy. These new materials provide enhanced thermal stability. They also offer lower moisture absorption rates. This is critical for durability in various applications.

High-frequency applications benefit from improved dielectric materials. These materials reduce signal loss and improve performance. They can withstand higher operating temperatures. However, developing these materials is complex. Manufacturers must balance performance with cost and availability. It's a challenging task that requires innovation and investment.

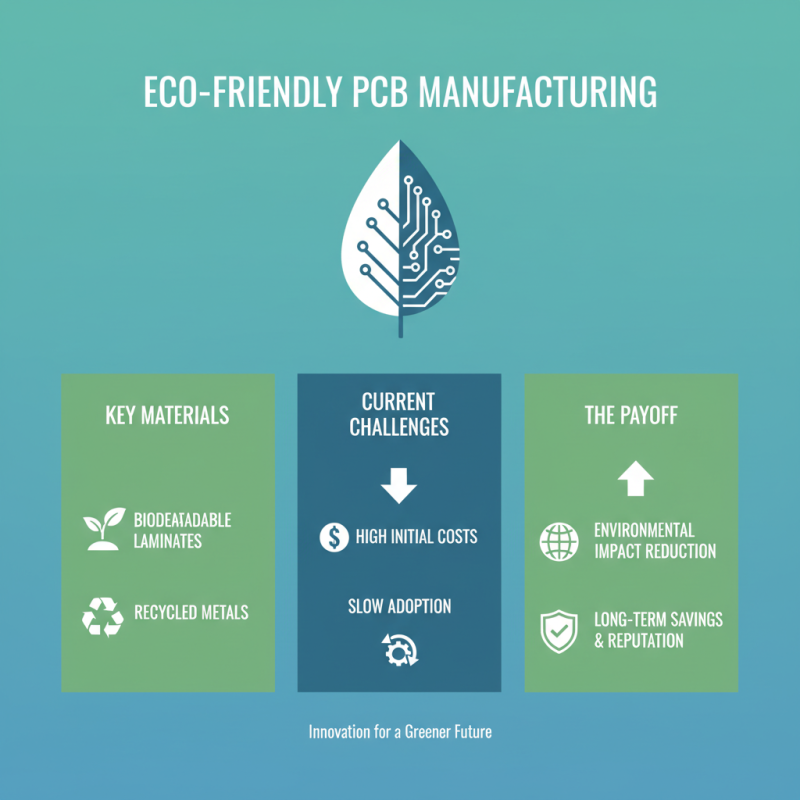

Another emerging trend is the use of biodegradable materials. They can reduce environmental impact significantly. Yet, they might not always offer the same durability. This raises questions regarding their long-term performance. The industry must assess their reliability in demanding conditions. As we push for sustainability, these compromises become more apparent. This is an ongoing discussion among professionals in the field.

Miniaturization Trends in PCB Design for Compact Electronic Devices

The trend of miniaturization in PCB design is reshaping the electronics landscape. Compact devices are becoming the norm. This push for smaller components is driven by consumer demand for portability. Designers face challenges in maintaining functionality while reducing size. Space constraints complicate the integration of more complex circuits.

Advanced materials play a role in overcoming these obstacles. Flexible substrates and thin designs enable efficient use of space. However, these innovations come with potential downsides. Sarcasm may arise in design meetings over the ongoing battle between size and complexity. The tiny traces on a PCB can easily lead to manufacturing issues if not executed correctly.

Despite the excitement, risks lurk in the details. Designers must consider heat dissipation in compact layouts. Without proper thermal management, devices can overheat. So, while miniaturization offers exciting possibilities, it also demands meticulous planning and execution. Each choice impacts the final product in ways that can surprise even seasoned engineers.

Sustainability Practices in PCB Manufacturing and Disposal

Sustainability is crucial in PCB manufacturing. Many companies focus on eco-friendly materials. There are biodegradable laminates and recycled metals available. However, adoption can be slow. The initial costs may deter some manufacturers.

Disposal of PCBs is a growing concern. Traditional methods can lead to environmental damage. Many materials are not easily recyclable. Some manufacturers are exploring alternative disposal methods. These include recovery of valuable metals. But, the effectiveness and efficiency of these methods need improvement.

Education and awareness are vital. Many industry players are still unaware of sustainable practices. Training programs can help bridge this gap. Collaboration is also essential. Sharing best practices can drive change. The journey toward sustainability in PCB production is ongoing and filled with challenges.

Related Posts

-

2025 Top PCB Printing Trends: What You Need to Know for Success

-

Revolutionizing PCB Printing: Insights from the 138th China Import and Export Fair 2025

-

Unlocking Success: The Advantages of Advanced PCB Fabrication Techniques for Global Buyers

-

Top PCB Printing Techniques That Improve Quality and Efficiency Guess Why

-

Unveiling PCB and Assembly Innovations at the 138th China Import and Export Fair 2025

-

Innovative Uses in Aerospace and Challenges in Best Circuit Board Fabrication