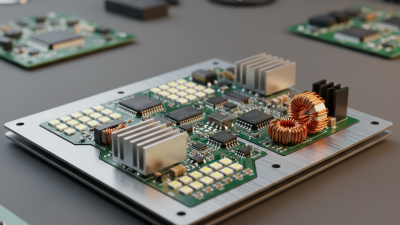

Founded in 2009, JHDPCB has more than 10 years of experience manufacturing full range of PCBs. From simple one or two layers PCBs to high complexity multi-layer PCBs. Low, medium or high volume – Whatever you need.Our goal is to be China’s TOP5 PCB manufacturer.We are committed to providing high-quality, industry-leading PCBs on time at competitive costs.You can rely on us to get the most cost-effective PCB by our expertise and large-scale production.